Non-pneumatic tire material taking thermoplastic vulcanized (TPV) as base material and preparation method of same

A non-pneumatic tire, thermoplastic vulcanization technology, applied in the field of modified polymer materials and non-pneumatic tires, can solve the requirements that the material cannot meet the compression deformation requirements of electric vehicle tires, reach 50 km/h, and the difficulty of recycling and recycling, etc. problems, to achieve high toughness, improved compatibility, and small compression set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

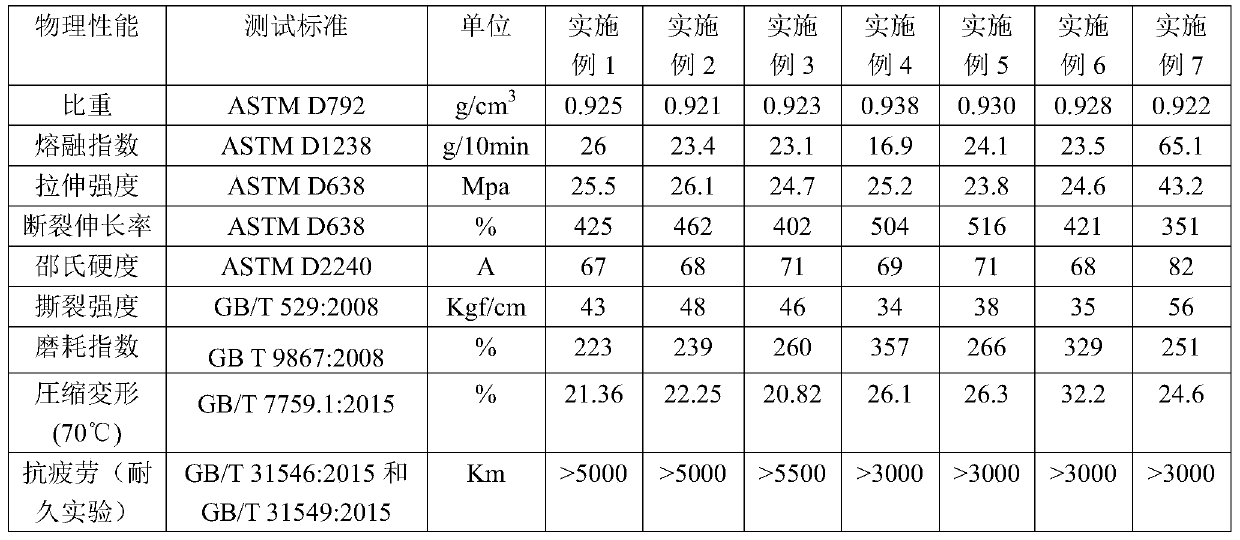

Examples

Embodiment 1

[0060] Embodiment 1 A kind of non-pneumatic tire material based on thermoplastic vulcanizate (TPV)

[0061] A non-pneumatic tire material based on thermoplastic vulcanizate (TPV) provided in this embodiment is composed of the following raw materials in weight percentage: thermoplastic vulcanizate: 28%, styrene elastomer: 10%, hydrogenated styrene elastomer : 15%, plasticizer: 20%, polypropylene: 8%, polyethylene: 4%, filler: 7%, compatibilizer: 2%, hyperbranched polymer: 1.0%, antioxidant: 0.2%, Wear-resistant anti-slip agent: 4.5%, UV absorber: 0.3%.

[0062] Raw material source:

[0063] Thermoplastic vulcanizate: a mixture of nitrile rubber / polyamide 6 and nitrile rubber / polyamide 12 in a weight ratio of 1:2.

[0064] Nitrile rubber / polyamide 6 is self-made, and it is made up of the raw material of following percentage by weight: Nitrile rubber (article number: 3245C, Nandi chemical industry): 50%, polyamide 6 (article number: 1013B, Japan Ube): 25%, Anti-aging agent (ar...

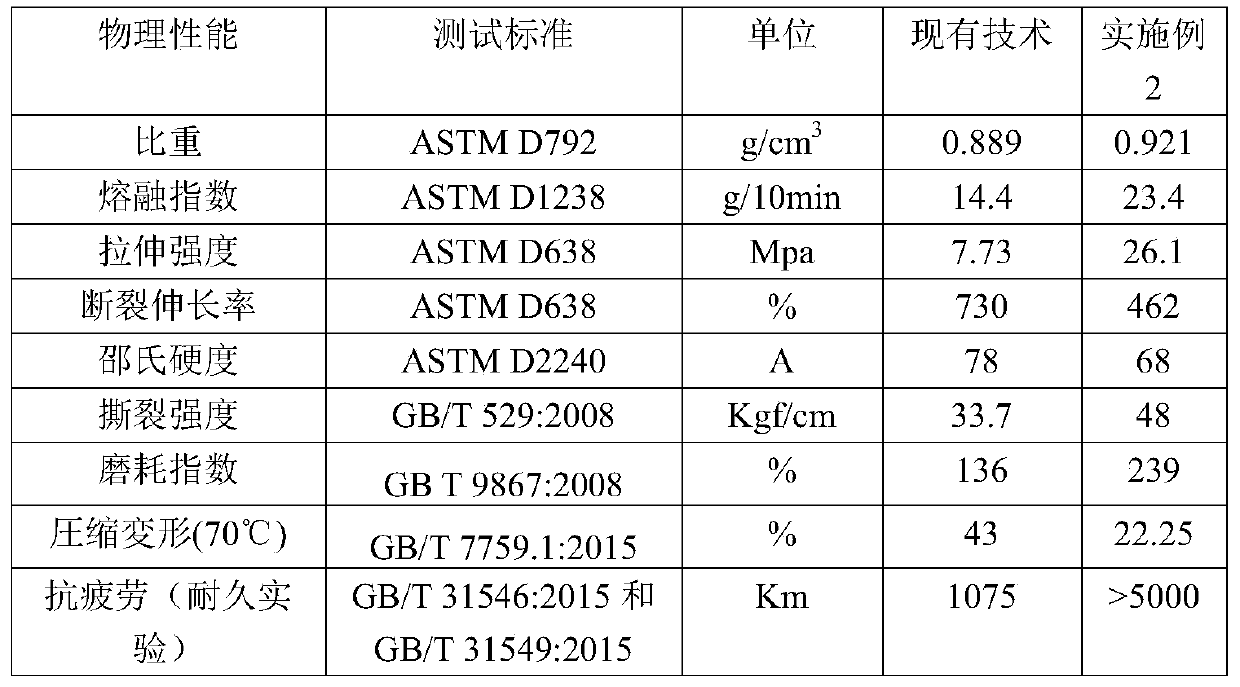

Embodiment 2

[0080] Embodiment 2 A kind of non-pneumatic tire material based on thermoplastic vulcanizate (TPV)

[0081] A non-pneumatic tire material based on thermoplastic vulcanizate (TPV) provided in this embodiment is composed of the following raw materials in weight percentage: thermoplastic vulcanizate: 30%, styrene elastomer: 8%, hydrogenated styrene elastomer : 18%, plasticizer: 18%, polypropylene: 8%, polyethylene: 4%, filler: 6%, compatibilizer: 2.5%, hyperbranched polymer: 1.5%, antioxidant: 0.2%, Wear-resistant anti-slip agent: 3.5%, UV absorber: 0.3%.

[0082] Raw material source:

[0083] Thermoplastic vulcanizate: a mixture of nitrile rubber / polyamide 6 and nitrile rubber / polyamide 12 in a weight ratio of 1:2.

[0084] Nitrile rubber / polyamide 6 is self-made, and it is made up of the raw material of following percentage by weight: Nitrile rubber (article number: 3245C, Nandi chemical industry): 50%, polyamide 6 (article number: 1013B, Japan Ube): 25%, Anti-aging agent (a...

Embodiment 3

[0100] Embodiment 3 A kind of non-pneumatic tire material based on thermoplastic vulcanizate (TPV)

[0101] A non-pneumatic tire material based on thermoplastic vulcanizate (TPV) provided in this embodiment is composed of the following raw materials in weight percentage: thermoplastic vulcanizate: 33%, styrene elastomer: 6%, hydrogenated styrene elastomer : 20%, plasticizer: 16%, polypropylene: 8%, polyethylene: 4%, filler: 5%, compatibilizer: 3%, hyperbranched polymer: 2%, antioxidant: 0.2%, Wear-resistant anti-slip agent: 2.5%, UV absorber: 0.3%.

[0102] Raw material source:

[0103] Thermoplastic vulcanizate: a mixture of nitrile rubber / polyamide 6 and nitrile rubber / polyamide 12 in a weight ratio of 1:2.

[0104] Nitrile rubber / polyamide 6 is self-made, and it is made up of the raw material of following percentage by weight: Nitrile rubber (article number: 3245C, Nandi chemical industry): 50%, polyamide 6 (article number: 1013B, Japan Ube): 25%, Anti-aging agent (artic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com