Polyolefin and nano calcium carbonate composite master batch and production method thereof

A nano-calcium carbonate and production method technology, applied in the field of polyolefin and nano-calcium carbonate composite masterbatch, can solve the problems of large specific surface area of nano-calcium carbonate, inability to achieve uniform blending, dust pollution of the production environment, etc., and achieve transparency without being affected impact, excellent environmental stress cracking properties, and good processing thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of production method of polyolefin and nano calcium carbonate composite masterbatch:

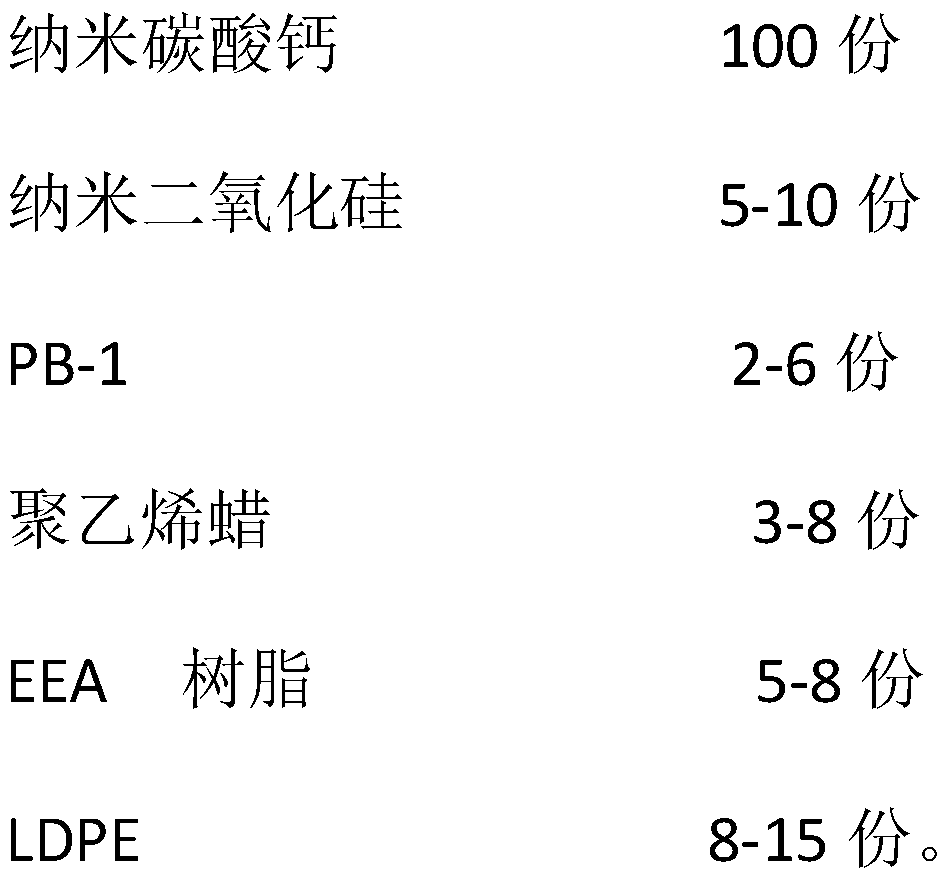

[0019] Include the following components in parts by mass:

[0020]

[0021]

[0022] The preparation method adopted is:

[0023] (1) The above-mentioned nano-calcium carbonate and hydrophobic nano-silicon dioxide are first put into a microwave dryer for drying. Then the material is sucked by the automatic metering vacuum into the first feeding port of the parallel in-line three-screw extruder.

[0024] (2) The above-mentioned EEA and LDPE are automatically metered and automatically fed into the second feeding port of the parallel in-line three-screw extruder.

[0025] (3) The above-mentioned PB and grafted polyethylene wax are automatically metered and vacuum-suctioned into the third feeding port of the parallel in-line three-screw extruder.

[0026] (4) The component materials are kneaded-kneaded-kneaded into a distributed and dispersed composite melt in the same dire...

Embodiment 2

[0028] A kind of production method of polyolefin and nano-calcium carbonate compound (blend) new masterbatch

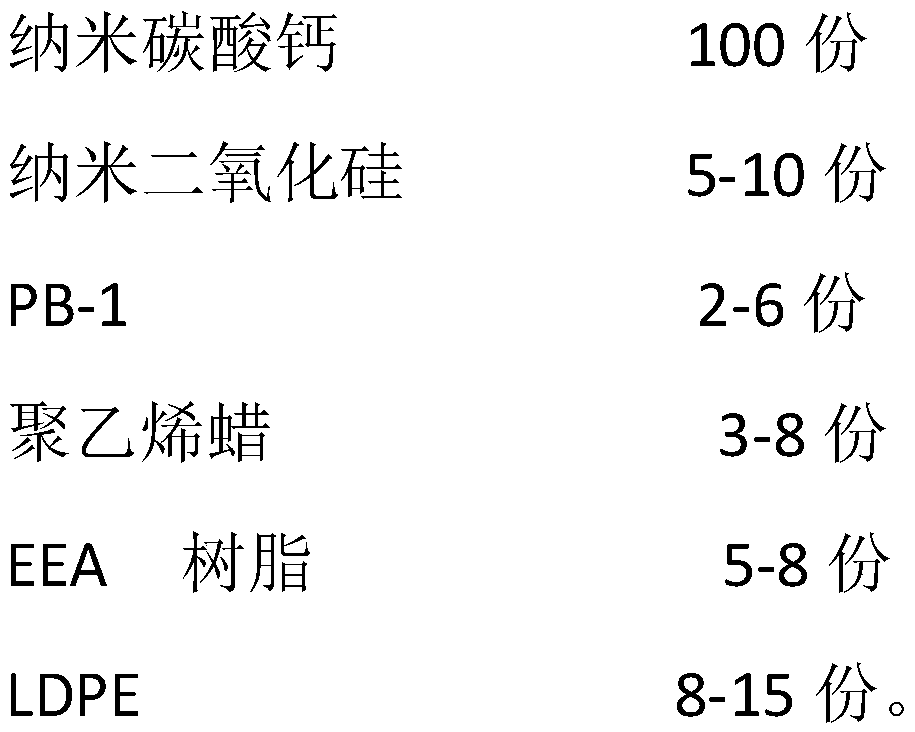

[0029] Include the following components in parts by mass:

[0030]

[0031]

[0032] The preparation method adopted is:

[0033] (1) The above-mentioned nano-calcium carbonate and hydrophobic nano-silicon dioxide are first put into a microwave dryer for drying. Then the material is sucked by the automatic metering vacuum into the first feeding port of the parallel in-line three-screw extruder.

[0034] (2) The above-mentioned EEA and LDPE are automatically metered and automatically fed into the second feeding port of the parallel in-line three-screw extruder.

[0035] (3) The above-mentioned PB and grafted polyethylene wax are automatically metered and vacuum-suctioned into the third feeding port of the parallel in-line three-screw extruder.

[0036](4) The component materials are kneaded-kneaded-kneaded into a distributed and dispersed composite melt in the ...

Embodiment 3

[0038] A kind of production method of polyolefin and nano calcium carbonate composite masterbatch

[0039] Include the following components in parts by mass;

[0040]

[0041]

[0042] The preparation method adopted is:

[0043] (1) The above-mentioned nano-calcium carbonate and hydrophobic nano-silicon dioxide are first put into a microwave dryer for drying. Then the material is sucked by the automatic metering vacuum into the first feeding port of the parallel in-line three-screw extruder.

[0044] (2) The above-mentioned EEA and LDPE are automatically metered and automatically fed into the second feeding port of the parallel in-line three-screw extruder.

[0045] (3) The above-mentioned PB and grafted polyethylene wax are automatically metered and vacuum-suctioned into the third feeding port of the parallel in-line three-screw extruder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com