Cadmium metal organic framework material as well as preparation method and application thereof

An organic framework, cadmium metal technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. The effect of low temperature and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 8mg Cd(NO 3 ) 2 ·3H 2 O and 6 mg H 5 L was added to a 10mL glass bottle; 4mL of DMF / C with a volume ratio of 2:1:2 was added to the glass bottle 2 h 5 OH / H 2 O and add 0.1mL of nitric acid solution dropwise to this mixed solution, seal the mixed solution, put it into a blast drying oven, and slowly heat it from room temperature to 90°C. The temperature was maintained at 90°C for 3000 min, and then the mixture was cooled to 30°C at a rate of 7°C / h to obtain white needle-like crystals.

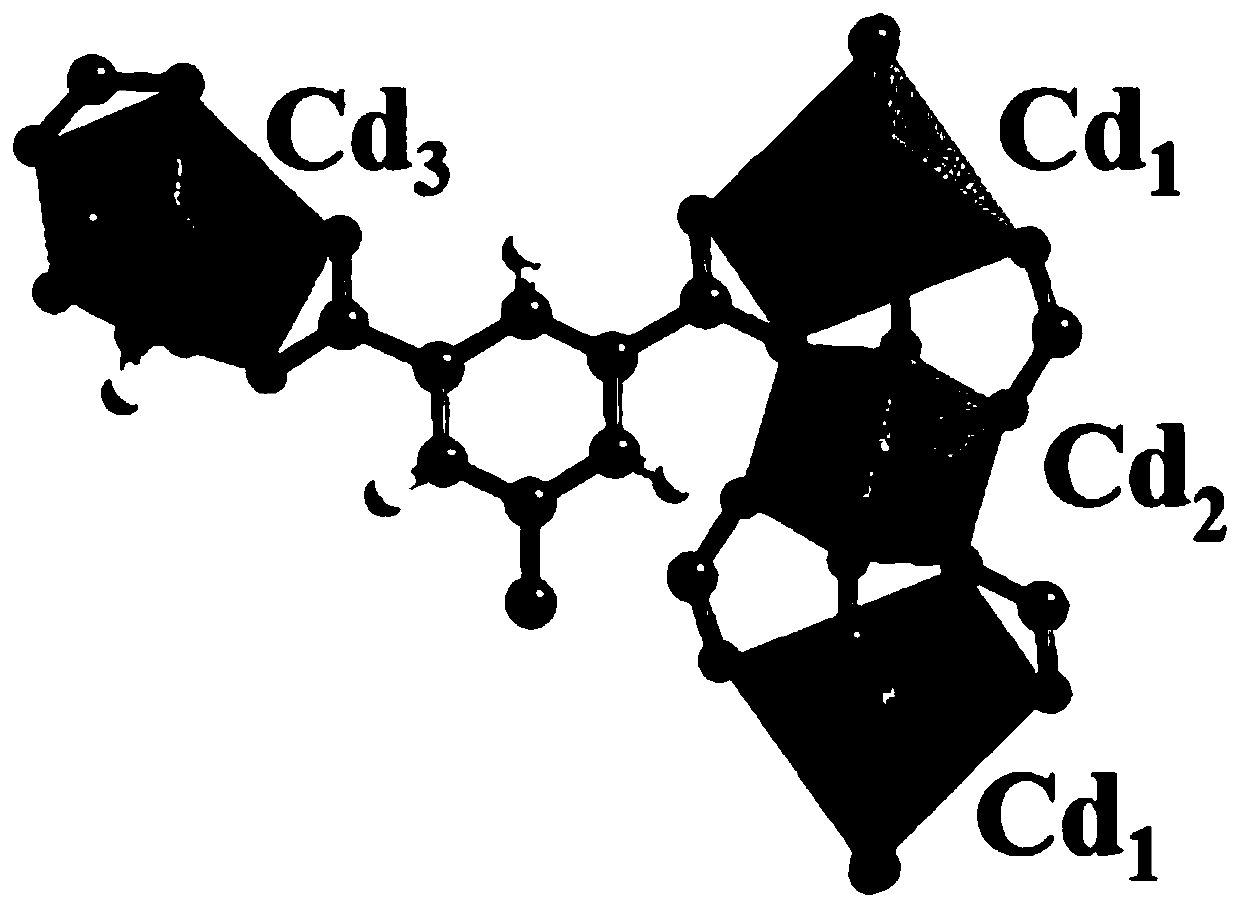

[0037] According to elemental analysis and single crystal diffraction data to determine the content of C, N, O, the elemental analysis results are shown in Table 1, and then determine the chemical formula of the metal organic framework material is C 28 Cd 3 o 15 h 32 N 2 .

[0038] Table 1 Elemental analysis results of white needle-like crystals

[0039] H / % C / % N / % measured value 4.01 34.90 3.34 Calculated 3.69 35.40 3.10

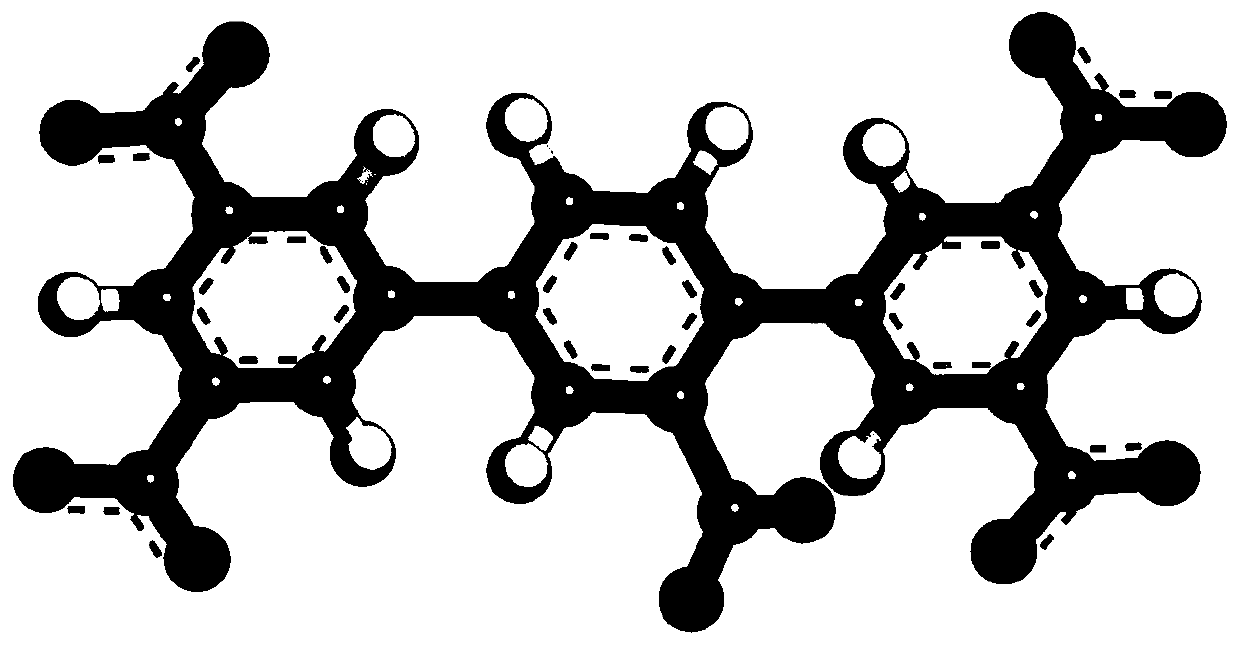

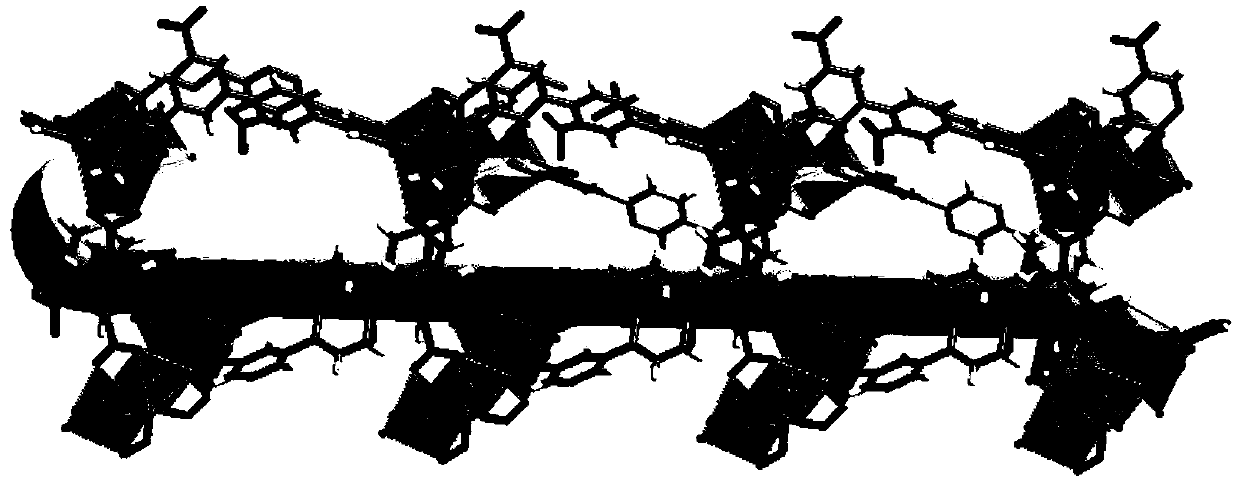

[0040] refer to Fi...

Embodiment 2

[0042] 9mg Cd(NO 3 ) 2 ·3H 2 O and 5 mg H 5 L was added to a 10mL glass bottle; 4mL of DMF / C with a volume ratio of 2:1:2 was added to the glass bottle 2 h 5 OH / H 2 O and add 0.1mL of nitric acid solution dropwise to this mixed solution, seal the mixed solution, put it into a blast drying oven, and slowly heat it from room temperature to 87°C. The temperature was maintained at 87 °C for 3000 min, and then the mixture was cooled to 25 °C at a rate of 6 °C / h to obtain white needle-like crystals.

[0043] Such as Figure 5 As shown, it can be seen from the figure that within the temperature range of 0-800°C, the thermogravimetric curve shows three distinct declines; in the first stage, 40°C-98°C, it corresponds to the loss of crystal water; In the second stage 98°C-240°C, the weight loss is 36.52%, the DMF solvent is lost, and the water molecules are coordinated. Above 360°C, the crystal skeleton begins to collapse.

Embodiment 3

[0045] 9mg Cd(NO 3 ) 2 ·3H 2 O and 5 mg H 5 L was added to a 10mL glass bottle; 4mL of DMF / C with a volume ratio of 2:1:2 was added to the glass bottle 2 h 5 OH / H 2 O and add 0.1mL of nitric acid solution dropwise to this mixed solution, seal the mixed solution, put it into a blast drying oven, and slowly heat it from room temperature to 92°C. The temperature was maintained at 92°C for 3000 min, and then the mixture was cooled to 30°C at a rate of 8°C / h to obtain white needle-like crystals.

[0046] The obtained white needle-like crystals were subjected to a powder diffraction test experiment, and the powder diffraction test (PXRD) was used to detect the phase purity of the prepared cadmium metal organic framework material at room temperature. Such as Figure 6 As shown, the diffraction pattern of the experimentally synthesized crystal sample is consistent with the diffraction pattern derived from the single crystal data cif file, indicating that the crystal sample cadm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com