A kind of polycarbonate antioxidant, preparation method and a kind of polycarbonate composition

A technology of polycarbonate and antioxidant, which is applied in the field of polycarbonate antioxidant, preparation, and polycarbonate composition, can solve the problems of low antioxidant use efficiency and increased production cost, and achieve good antioxidant capacity, Reduced dosage and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

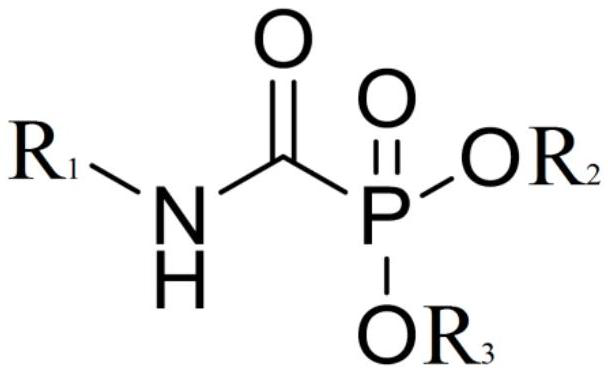

Method used

Image

Examples

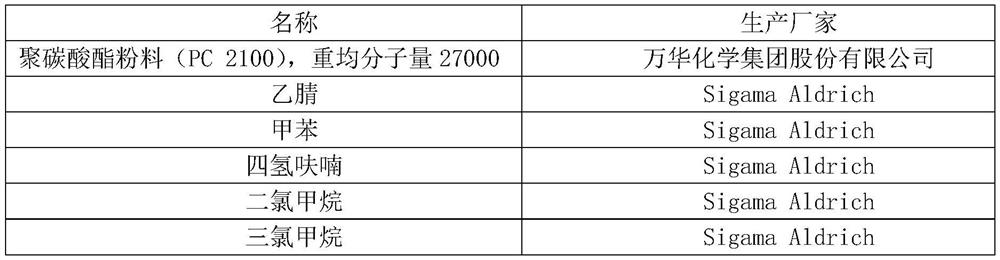

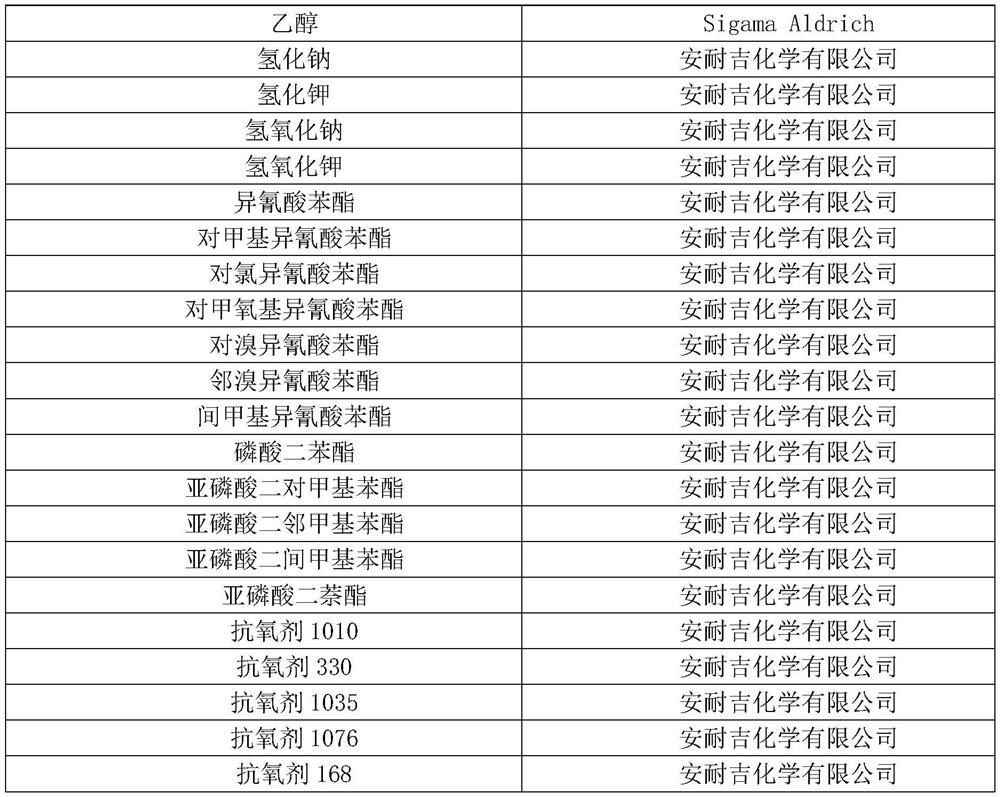

Embodiment 1

[0036] A reactor of acetonitrile (10 mL) and phosphite (4.68 g, 20 mmol) was added sequentially, and sodium hydrogen fluid was added to the reactor multiple times. (0.576 g, 24mmol), the temperature of the reaction system is 60 ° C, after the sodium hydrogen fluid is completely dissolved, the temperature to the boiling point of the acetonitrile is 80 ° C for reflux, after which 25 ml of constant voltage drops can be applied, dripped from the constant pressure droplet funnel into isocyanic acid Phenyl ester (4.28 g, 36 mmol) 10 ml acetonitrile solution, reflux reaction 2H, filtrate, filtrate, evaporate the solvent in the filtrator to give a crude product. The resulting crude product was recrystallized with acetonitrile to extract the white solid in which the polycarbonate antioxidant A was 6.78 g, and the yield was 96%. The reaction is as follows:

[0037]

[0038] 1 H NMR (CDCL 3 500MHz): Δ9.08-9.22 (m, 1H), 7.58-7.62 (m, 2H), 7.25-7.32 (M, 4H), 7.15-7.22 (M, 7H) .

[0039] Then...

Embodiment 2

[0042] Toluene (10 mL) and phosphite (4.68 g, 20 mmol) were sequentially added to the reactor equipped with a thermometer, reflow the condensed tube, and constant pressure drops, and add sodium hydride to the reactor multiple times (0.96 g, 40 mmol), the control reaction system temperature is 95 ° C, and the temperature to the sodium hydrogen is completely dissolved, the temperature to the boiling point of the toluene is refluxed. After installing 25 ml of constant pressure drops, the solubility is dripped from the constant pressure droplet funnel. Phenocyanate (5.32 g, 40 mmol) 10 ml toluene solution, reflux reaction for 2 h, filtrate filtrate, and the solvent in the filtrator was evaporated to give a crude product. The resulting crude product was recrystallized with acetonitrile, and the white solid in which the polycarbonate antioxidant B was 6.75 g, and the yield was 92%. The reaction is as follows:

[0043]

[0044] 1 H NMR (CDCL 3500MHz): Δ9.11-9.32 (m, 1H), 7.02-7.32 (m, ...

Embodiment 3

[0047] Tetrahydrofuran (10 mL) and phosphite 2 oxoethylanter (5.24 g, 20 mmol) were sequentially added to reactors equipped with a thermometer, reflow the condensed tube, and constant voltage drops, which were added to the reactor to add potassium hydride into the reactor. 1.203g, 30 mmol), the temperature of the reaction system is 45 ° C, and the potassium to be hydrolyzed is completely dissolved, and the temperature to the boiling point of tetrahydrofuran is refluxed. After installing 25 ml of constant voltage drops, it is dripped from the constant pressure droplet funnel. The 10 ml of chlorocyanate (6.91 g, 45 mmol) of 10 ml of tetrahydrofuran, refluxed reaction 2H, filtrate, filtered, and the solvent in the filtrator was evaporated to give a crude product. The obtained crude product was recrystallized with acetonitrile, and the white solid in which the polycarbonate antioxidant was extracted, and the yield was 98%. The reaction is as follows:

[0048]

[0049] 1 H NMR (CDCL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com