Environment-friendly slow-release compound fertilizer and preparation method thereof

A compound fertilizer and compound fertilizer technology, applied in the field of environment-friendly slow-release compound fertilizer and its preparation, can solve the problems of low nutritional value, high price, long release period, etc. sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

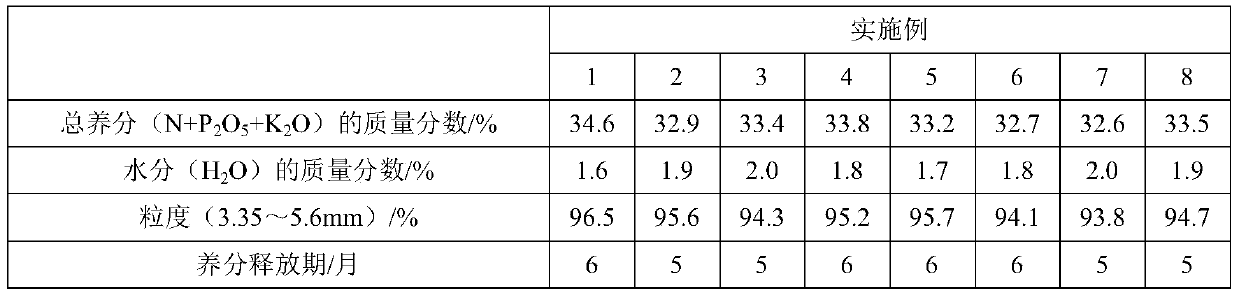

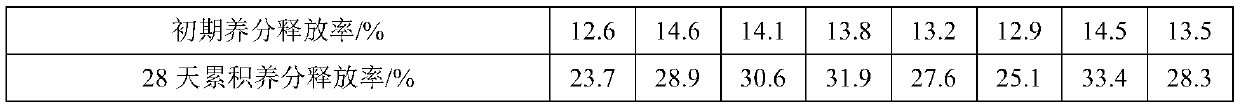

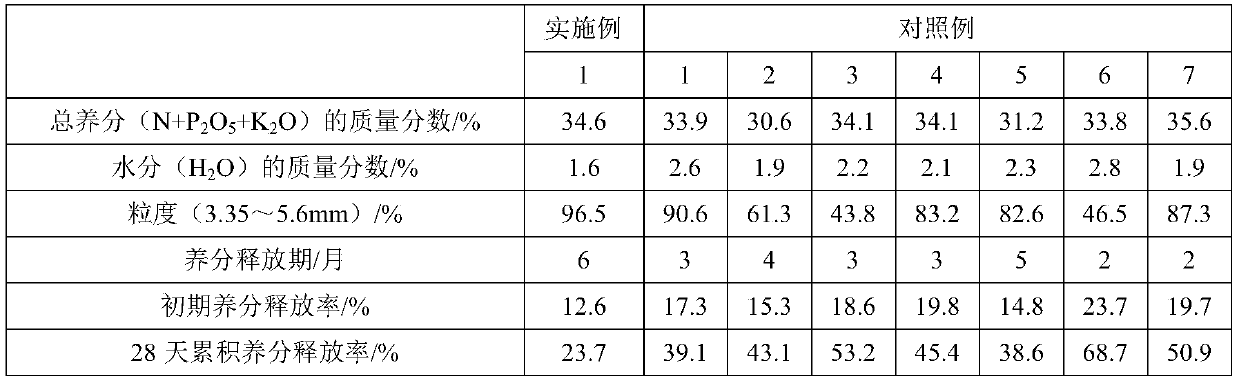

Examples

Embodiment 1

[0034] An environmentally friendly slow-release compound fertilizer, prepared by the following steps:

[0035] (1), weigh 8 parts of polylactic acid powder, 4.3 parts of polyvinyl alcohol powder, 2.2 parts of Sr-10 emulsifier, 0.02 part of 184 photoinitiator and 3.6 parts of methoxy polyethylene glycol 550 monomethacrylate and add Into the reaction kettle, the stirring speed is 60r / min, the reaction is maintained at a system temperature of 30°C for 20min, the product is illuminated by a 40W LED light for 5s, and 19 parts of polyvinyl alcohol aqueous solution (mass concentration is 0.9%) is added to the reaction kettle, and stirred The speed is 70r / min, the mixing temperature is 50°C for 15min, and the material is freeze-dried at -50°C for 2h. After the product is crushed, add the product, 2.8 parts of Trichoderma and 3.9 parts of earthworm secretion to the mixer, and the mixing speed is 60r / min, the mixing temperature is 30°C and mixed for 20min to obtain the outer covering f...

Embodiment 2

[0041] An environmentally friendly slow-release compound fertilizer, prepared by the following steps:

[0042] (1), weigh 8 parts of polylactic acid powder, 3 parts of polyvinyl alcohol powder, 2 parts of Sr-10 emulsifier, 0.01 part of 184 photoinitiator and 3 parts of methoxy polyethylene glycol 550 monomethacrylate and add Into the reaction kettle, the stirring speed is 60r / min, and the reaction is maintained at the system temperature of 30°C for 20min. The temperature is 50°C and mixed for 15 minutes, and the material is freeze-dried at -50°C for 2 hours. After the product is pulverized, add the product, 1 part of Trichoderma and 2 parts of earthworm secretion to the mixer, the mixing speed is 60r / min, and the mixing temperature is 30 Mix for 20 minutes at ℃ to obtain the outer covering film material;

[0043] (2) Weigh 31 parts of meat and bone meal, 62 parts of water and 5 parts of acetic acid into the hydrothermal reaction kettle, maintain the hydrothermal reaction temp...

Embodiment 3

[0048] An environmentally friendly slow-release compound fertilizer, prepared by the following steps:

[0049] (1), weigh 8 parts of polylactic acid powder, 6 parts of polyvinyl alcohol powder, 5 parts of Sr-10 emulsifier, 0.05 part of 184 photoinitiator and 8 parts of methoxy polyethylene glycol 550 monomethacrylate and add Put into the reaction kettle, the stirring speed is 60r / min, keep the system temperature at 30°C and react for 20min, the product is illuminated by 400W LED light for 2s, add 29 parts of polyvinyl alcohol aqueous solution to the reaction kettle, the stirring speed is 70r / min, mix The temperature was 50°C and mixed for 15 minutes, and the material was freeze-dried at -50°C for 2 hours. After the product was crushed, the product, 7 parts of Trichoderma and 6 parts of earthworm secretions were added to the mixer, the mixing speed was 60r / min, and the mixing temperature was 30 Mix for 20 minutes at ℃ to obtain the outer covering film material;

[0050] (2) We...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com