Phosphotungstic heteropolyacid salt catalyst for synthesizing epoxy chloropropane and preparation method thereof

A technology of phosphotungstic heteropoly salt and epichlorohydrin, which is applied in the field of catalytic chemistry, can solve the problems that the conversion rate of propylene is only 93% and unfavorable production, and achieve the effects of convenient catalyst recovery, low production cost and safe raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

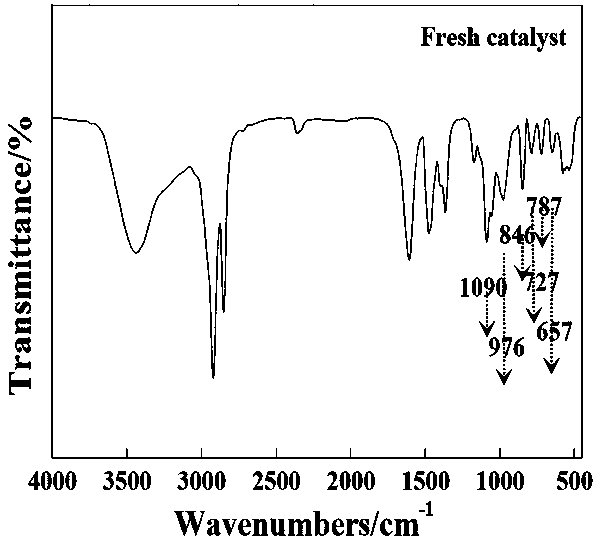

Image

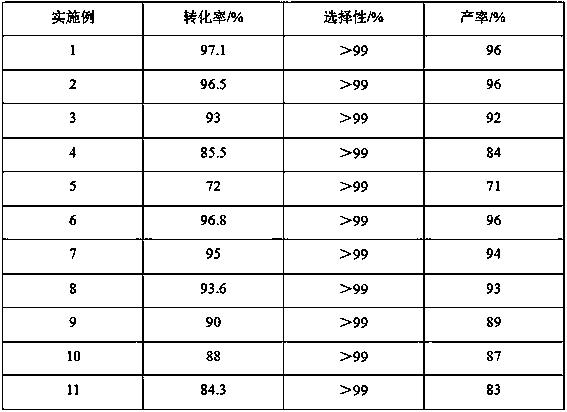

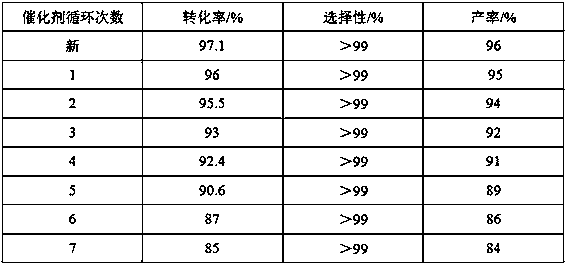

Examples

Embodiment 1

[0014] Add 1.152 kg of solid phosphotungstic acid and 1.7 L of 30% hydrogen peroxide into a 5 L glass reactor, and stir at room temperature in the dark. At the same time, 0.727 kg of dimethyl dioctadecyl ammonium chloride and 8 L of absolute ethanol were added to a 50 L glass reactor, and heated to dissolve at 40°C. After 2 hours, the peroxyphosphotungstic acid solution obtained in the 5 L glass reactor was added dropwise to the 50 L glass reactor with a metering pump. After the addition was completed, the stirring reaction was continued at 40°C for 2 h. After the reaction, cool to room temperature and filter under reduced pressure to obtain a crude catalyst white powder. Wash the white powder with 40 L of distilled water, then wash with 10 L of ethanol, filter, and vacuum-dry at 40°C for 6 h to obtain a white catalyst powder totaling 1.776 kg.

Embodiment 2

[0016] Add 1.152 kg of solid phosphotungstic acid and 1.7 L of 30% hydrogen peroxide into a 5 L glass reactor, and stir at room temperature in the dark. At the same time, 0.727 kg of dimethyl dioctadecyl ammonium chloride and 8 L of absolute ethanol were added to a 50 L glass reactor, and heated to dissolve at 45°C. After 2 hours, the peroxyphosphotungstic acid solution obtained in the 5 L glass reactor was added dropwise to the 50 L glass reactor with a metering pump. After the addition was completed, the stirring reaction was continued at 45°C for 2 h. After the reaction, cool to room temperature and filter under reduced pressure to obtain a crude catalyst white powder. Wash the white powder with 40 L of distilled water, then wash with 10 L of ethanol, filter, and vacuum-dry at 40°C for 6 h to obtain a white catalyst powder totaling 1.764 kg.

Embodiment 3

[0018] Add 1.152 kg of solid phosphotungstic acid and 1.7 L of 30% hydrogen peroxide into a 5 L glass reactor, and stir at room temperature in the dark. At the same time, 0.727 kg of dimethyl dioctadecyl ammonium chloride and 8 L of absolute ethanol were added to a 50 L glass reactor, and heated to dissolve at 50°C. After 2 hours, the peroxyphosphotungstic acid solution obtained in the 5 L glass reactor was added dropwise to the 50 L glass reactor with a metering pump. After the addition was completed, the stirring reaction was continued at 50°C for 2 h. After the reaction, cool to room temperature and filter under reduced pressure to obtain a crude catalyst white powder. Wash the white powder with 40 L of distilled water, then wash with 10 L of ethanol, filter, and vacuum-dry at 40°C for 6 h to obtain a white catalyst powder totaling 1.730 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com