Preparation and application of phosphorus-doped cobalt telluride nano material

A technology of nanomaterials and phosphorus doping, which is applied in the fields of electrochemistry, composite materials and preparation, can solve the problems of large overpotential, etc., and achieve the effects of high conductivity, easy product structure and small batch difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Co. 3 o 4 Preparation of nanosheets: Take 291 mg of Co(NO 3 ) 2 •6H 2 O and 300 mg urea were dissolved in 35 mL of deionized water and stirred for 30 minutes to form a homogeneous solution; the mixed solution was transferred to a 50 mL stainless steel autoclave lined with polytetrafluoroethylene, and hydrothermally reacted at 120 °C for 6 hours; the reaction After the end, the reactor was cooled to room temperature, and the precipitated product was washed with deionized water and ethanol for 3 to 4 times, and then dried in a vacuum oven at 60°C for 8 hours; °C (heating rate is 2 °C min -1 ) and calcined for 2 hours to obtain Co 3 o 4 Nanosheets;

[0033] (2) CoTe 2 Preparation of nanosheets: take the above synthesized Co 3 o 4 100 mg of nanosheets, and 200 mg of Te powder were ground evenly in a mortar, at 5°C min -1 The temperature was raised to 680°C and calcined for 2 hours to obtain CoTe 2 Nanosheets;

[0034] (3) P-CoTe 2 Preparation of nanopartic...

Embodiment 2

[0037] (1) Co. 3 o 4 Preparation of nanosheets: same as Example 1;

[0038] (2) CoTe 2 Preparation of nanosheets: same as Example 1;

[0039] (3) P-CoTe 2 Preparation of nanoparticles: 100 mg CoTe 2 The nanosheets and 200 mg of sodium hypophosphite were uniformly ground in a mortar, and the sample was heated to 300 °C in an Ar atmosphere (heating rate 2 °C min -1 ) and calcined for 120 minutes; then cooled to room temperature, the product was washed three times with deionized water and ethanol, and dried in a vacuum oven at 60°C for 4 hours to obtain P-CoTe 2 Nanoparticles;

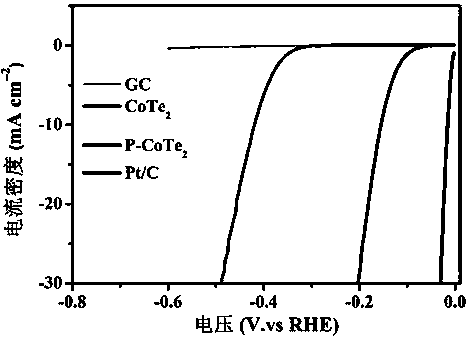

[0040] (4) P-CoTe 2 Catalytic Hydrogen Evolution Performance Test of Nanoparticle Electrode: P-CoTe 2 Current density is 10mAcm in acidic environment -2 , the overpotential is 192mV; the current density is 10 mAcm in alkaline conditions -2 , the overpotential is 198mV.

Embodiment 3

[0042] (1) Co. 3 o 4 Preparation of nanosheets: same as Example 1;

[0043] (2) CoTe 2 Preparation of nanosheets: same as Example 1;

[0044] (3) P-CoTe 2 Preparation of nanoparticles: 100 mg CoTe 2 The nanosheets and 300 mg of sodium hypophosphite were ground evenly in a mortar, and the sample was heated to 300 °C in an Ar atmosphere (heating rate 2 °C min -1 ) and calcined for 120 minutes; then cooled to room temperature, the product was washed three times with deionized water and ethanol, and dried in a vacuum oven at 60°C for 4 hours to obtain P-CoTe 2 Nanoparticles;

[0045] (4) P-CoTe 2 Catalytic hydrogen evolution performance test of nanoparticle electrode: current density is 10 mAcm in acidic environment -2 , with an overpotential of 210mV and a current density of 10 mAcm in alkaline conditions -2 , the overpotential is 218mV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com