Yellowing-resistant aqueous adhesive and preparation method thereof

An adhesive, anti-yellowing technology, used in adhesives, adhesive types, adhesive additives, etc., can solve the problems of affecting product appearance and quality, low 180° peel strength, poor bonding performance, etc., to prolong the appearance. and quality time, good high/low temperature resistance, good yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

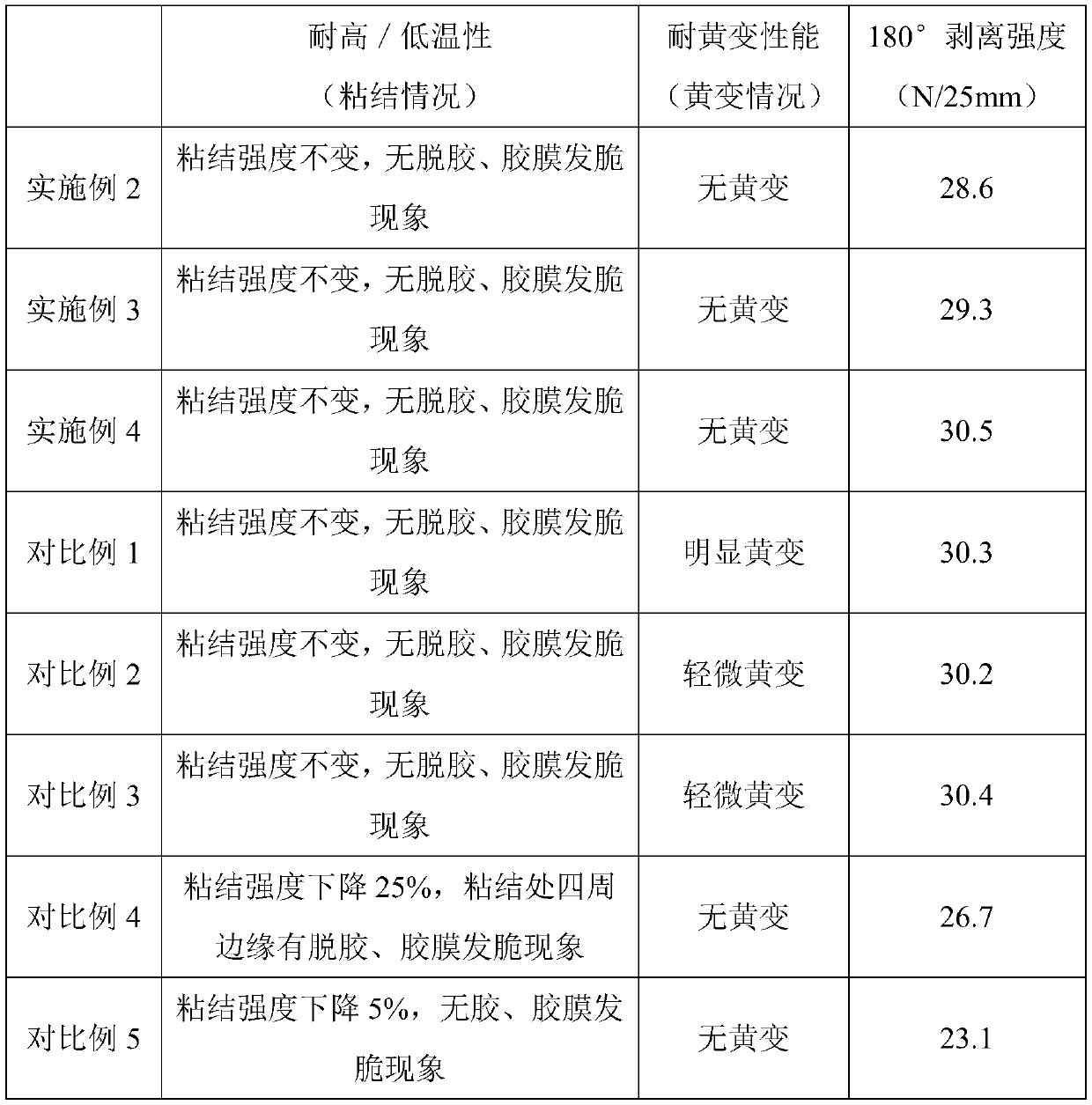

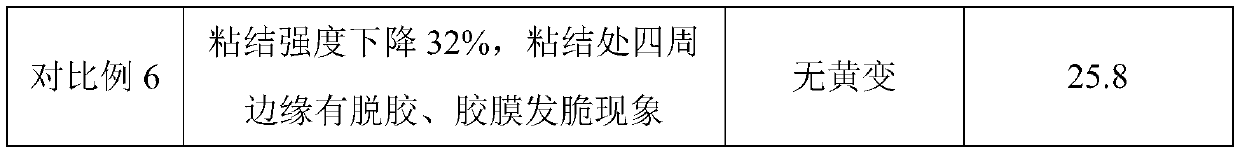

Examples

Embodiment 1

[0035] An anti-yellowing water-based adhesive, made of the following raw materials in parts by weight: 38-48 parts of polyvinyl alcohol, 23-29 parts of water-soluble polyvinyl formal, 28-35 parts of water-based ethylene-vinyl acetate copolymer 12-16 parts of silicone acrylic emulsion, 2-4 parts of emulsifier, 3-6 parts of ultraviolet absorber, 2.5-4 parts of antioxidant; the ultraviolet absorber is 2-(2ˊ-hydroxyl-5ˊ-methylbenzene base) a mixture of benzotriazole and resorcinol monobenzoate.

[0036] Preferably, the anti-yellowing water-based adhesive is made of the following raw materials in parts by weight: 43 parts of polyvinyl alcohol, 26.5 parts of water-soluble polyvinyl formal, 31.5 parts of water-based ethylene-vinyl acetate copolymer, silicone acrylic 14 parts of emulsions, 3.2 parts of emulsifiers, 4.8 parts of ultraviolet absorbers, and 3.6 parts of antioxidants; A mixture of quinone esters.

[0037] Preferably, in the mixture of 2-(2'-hydroxyl-5'-methylphenyl) ben...

Embodiment 2

[0046] An anti-yellowing water-based adhesive, made of the following raw materials in parts by weight: 38 parts of polyvinyl alcohol, 23 parts of water-soluble polyvinyl formal, 28 parts of water-based ethylene-vinyl acetate copolymer, 12 parts of silicon-acrylic emulsion 2 parts, 2 parts of emulsifier, 3 parts of ultraviolet absorber, 2.5 parts of antioxidant; Described ultraviolet absorber is 2-(2'-hydroxyl-5'-methylphenyl) benzotriazole and isophthalic acid monobenzoic acid A mixture of phenolic esters.

[0047] In this example, in the mixture of 2-(2'-hydroxy-5'-methylphenyl)benzotriazole and resorcinol monobenzoate, 2-(2'-hydroxyl-5'-methyl The mass ratio of phenyl)benzotriazole to resorcinol monobenzoate is 1:0.6.

[0048] In this embodiment, the polyvinyl alcohol is 1799 type polyvinyl alcohol.

[0049] In this embodiment, the emulsifier is cocoamine polyoxyethylene ether.

[0050] In this embodiment, the antioxidant is tetrakis[β-(3,5-di-tert-butyl 4-hydroxyphenyl) ...

Embodiment 3

[0057] An anti-yellowing water-based adhesive, made of the following raw materials in parts by weight: 48 parts of polyvinyl alcohol, 29 parts of water-soluble polyvinyl formal, 35 parts of water-based ethylene-vinyl acetate copolymer, 16 parts of silicon acrylic emulsion part, 4 parts of emulsifier, 6 parts of ultraviolet absorber, 4 parts of antioxidant; Described ultraviolet absorber is 2-(2'-hydroxyl-5'-methylphenyl) benzotriazole and monobenzoic acid A mixture of phenolic esters.

[0058] In this example, in the mixture of 2-(2'-hydroxy-5'-methylphenyl)benzotriazole and resorcinol monobenzoate, 2-(2'-hydroxyl-5'-methyl The mass ratio of phenyl)benzotriazole to resorcinol monobenzoate is 1:0.7.

[0059] In this embodiment, the polyvinyl alcohol is 1799 type polyvinyl alcohol.

[0060] In this embodiment, the emulsifier is cocoamine polyoxyethylene ether.

[0061] In this embodiment, the antioxidant is tetrakis[β-(3,5-di-tert-butyl 4-hydroxyphenyl) propionate] pentaeryth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com