Preparation method of hole sealing agent of aluminum alloy anode oxidation film

An anodic oxide film and sealing agent technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problem of being easily oxidized by high temperature, unable to reach the sealing depth, and the sealing penetration depth of inorganic machine sealing agents. Low problems, to avoid being oxidized, to improve the viscosity and dispersion effect, and to improve the penetration depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

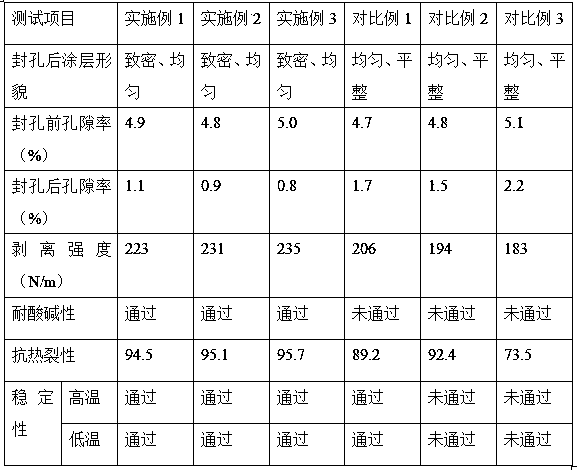

Examples

Embodiment 1

[0032] Preparation of aluminum citrate xerogel:

[0033] In parts by weight, mix 40 parts of citric acid solution with a mass fraction of 20% and 5 parts of aluminum nitrate in a beaker, place the beaker in a water bath, heat up to 70°C, and stir for 40 minutes to obtain aluminum citrate Gel, put the aluminum citrate gel in an oven, heat up to 100°C, and dry for 6 hours to obtain the aluminum citrate xerogel, which is stored in a sealed bag.

[0034] Preparation of carbon-coated aluminum nanoparticles:

[0035] In parts by weight, take 20 parts of aluminum citrate xerogel, 30 parts of colloidal graphite, and 50 parts of cyclotrimethyltrinitramine and mix them into a high-pressure airtight container, and fill the high-pressure airtight container with a volume ratio of 3:1 Nitrogen and argon gas were ignited and detonated with a lead wire, and left to stand for 10 minutes to collect carbon-coated aluminum nanoparticles.

[0036] Preparation of active molybdenite powder:

[00...

Embodiment 2

[0045] Preparation of aluminum citrate xerogel:

[0046] In parts by weight, mix 45 parts of citric acid solution with a mass fraction of 20% and 6 parts of aluminum nitrate in a beaker, place the beaker in a water bath, heat up to 73°C, and stir for 45 minutes to obtain aluminum citrate Gel, put the aluminum citrate gel in an oven, heat up to 105°C, and dry for 6 hours to obtain the aluminum citrate xerogel, which is stored in a sealed bag.

[0047] Preparation of carbon-coated aluminum nanoparticles:

[0048] In parts by weight, take 23 parts of aluminum citrate dry gel, 35 parts of colloidal graphite, and 55 parts of cyclotrimethyltrinitramine and mix them into a high-pressure airtight container, and fill the high-pressure airtight container with a volume ratio of 3:1 Nitrogen and argon gas were ignited and detonated with a lead wire, and left to stand for 13 minutes to collect carbon-coated aluminum nanoparticles.

[0049] Preparation of active molybdenite powder:

[00...

Embodiment 3

[0058] Preparation of aluminum citrate xerogel:

[0059] In parts by weight, mix 50 parts of citric acid solution with a mass fraction of 20% and 8 parts of aluminum nitrate in a beaker, place the beaker in a water bath, heat up to 75°C, and stir for 50 minutes to obtain aluminum citrate Gel, put the aluminum citrate gel in an oven, heat up to 110°C, and dry for 7 hours to obtain the aluminum citrate xerogel, which is stored in a sealed bag.

[0060] Preparation of carbon-coated aluminum nanoparticles:

[0061] In parts by weight, take 25 parts of aluminum citrate dry gel, 40 parts of colloidal graphite, and 60 parts of cyclotrimethyltrinitramine and mix them into a high-pressure airtight container, and fill the high-pressure airtight container with a volume ratio of 3:1 Nitrogen and argon gas were ignited and detonated with a lead wire, and left to stand for 15 minutes to collect carbon-coated aluminum nanoparticles.

[0062] Preparation of active molybdenite powder:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com