Thixotropic heat conduction insulating sealant and preparation method thereof

A heat-conducting insulation and sealant technology, applied in the field of sealants, can solve problems such as poor mechanical properties, thixotropic damage of sealants, and large proportion of metal oxides, and achieve the effect of good mechanical properties and good thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

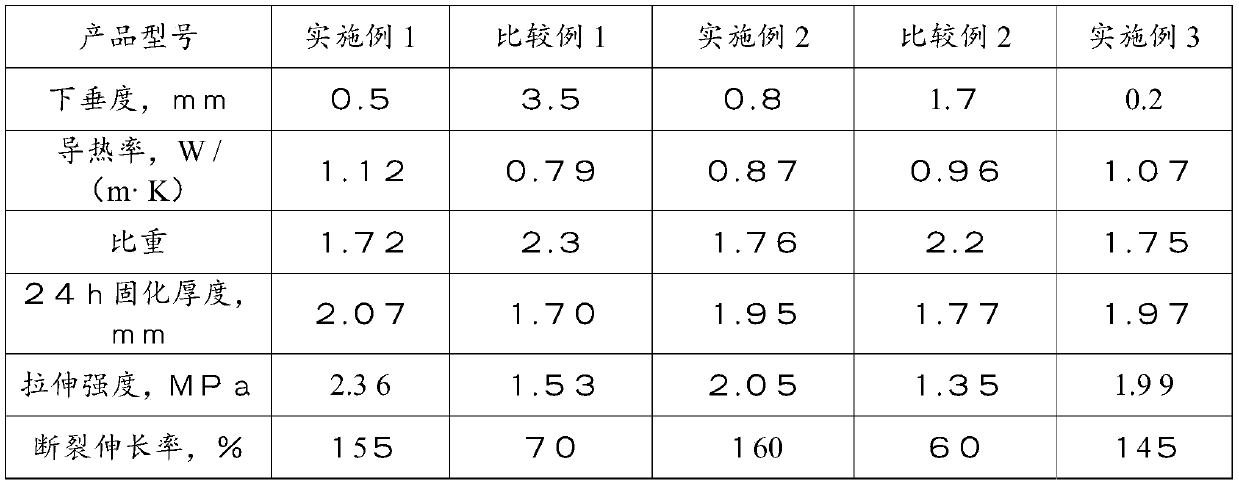

Examples

Embodiment 1

[0030] An embodiment of the thixotropic thermally conductive and insulating sealant of the present invention, the thixotropic thermally conductive and insulating sealant in this embodiment contains the following ingredients in parts by weight:

[0031] 100 parts of hydroxyl-terminated polydimethylsiloxane, 200 parts of silicon micropowder, 100 parts of zinc oxide, 15 parts of nano-calcium carbonate, and 5 parts of hydrophobic fumed silica;

[0032] The particle diameter of the silicon micropowder is 5 μm; the particle diameter of the zinc oxide is 2 μm; the viscosity of the polydimethylsiloxane at 25° C. is 3000 cps; the particle diameter of the nano calcium carbonate is 40 nanometers; The specific surface area of the hydrophobic type fumed silica is 180m 2 / g;

[0033] The preparation method of the thixotropic thermally conductive insulating sealant described in this embodiment is as follows:

[0034] (1) In the planetary stirring tank, add polydimethylsiloxane, silicon m...

Embodiment 2

[0040] An embodiment of the thixotropic thermally conductive and insulating sealant of the present invention, the thixotropic thermally conductive and insulating sealant in this embodiment contains the following ingredients in parts by weight:

[0041] 100 parts of hydroxyl-terminated polydimethylsiloxane, 250 parts of silicon micropowder, 50 parts of zinc oxide, and 35 parts of nano-calcium carbonate;

[0042] The particle size of the silicon micropowder is 2 μm; the particle size of the zinc oxide is 5 μm; the viscosity of the polydimethylsiloxane at 25° C. is 1500 cps; the particle size of the nano-calcium carbonate is 80 nm.

[0043] The preparation method of the thixotropic heat-conducting insulating sealant described in the present embodiment is as follows:

[0044] (1) In the planetary stirring tank, add hydroxyl-terminated polydimethylsiloxane, silicon micropowder, zinc oxide, and active nano-calcium carbonate, mix well and heat up to 120°C, in a vacuum of 0.085MPa and a...

Embodiment 3

[0049] An embodiment of the thixotropic thermally conductive and insulating sealant of the present invention, the thixotropic thermally conductive and insulating sealant in this embodiment contains the following ingredients in parts by weight:

[0050] 100 parts of hydroxyl-terminated polydimethylsiloxane, 200 parts of silicon micropowder, 50 parts of zinc oxide, and 12 parts of hydrophobic fumed silica;

[0051] The particle size of the silicon micropowder is 10 μm; the particle size of the zinc oxide is 2 μm; the viscosity of the polydimethylsiloxane at 25° C. is 5000 cps; the specific surface area of the hydrophobic fumed silica is 200 m 2 / g;

[0052] The preparation method of the thixotropic thermally conductive and insulating sealant described in this embodiment is as follows:

[0053] (1) In the planetary stirring tank, add hydroxyl-terminated polydimethylsiloxane, silicon micropowder, zinc oxide, and active nano-calcium carbonate, mix well and heat up to 120°C, in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com