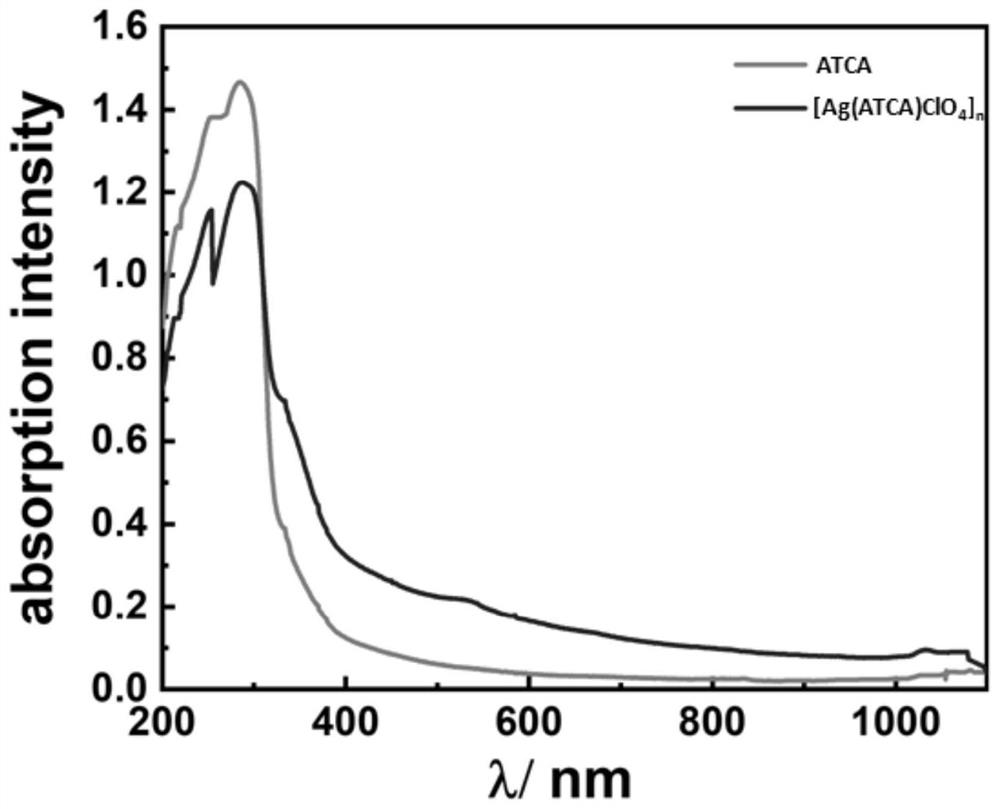

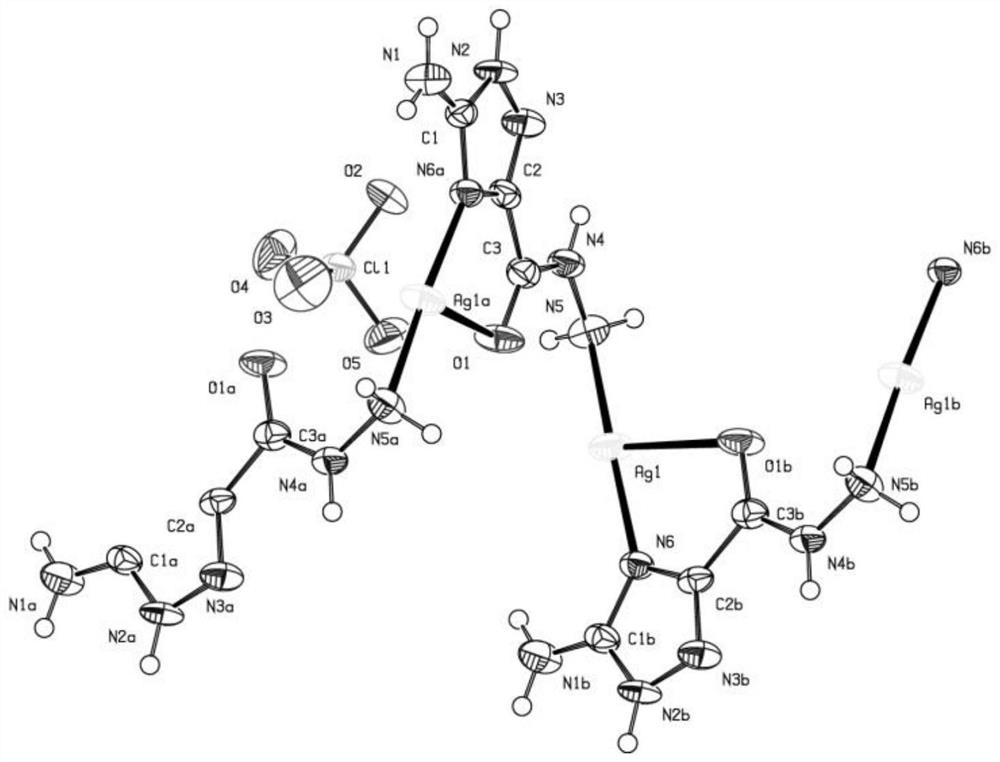

Application of a Silver-Based Cationic Energetic Metal-Organic Framework as a Formulation of Laser Direct Initiating Agent

A metal-organic framework and laser direct technology, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve problems such as personnel and property losses, accidental explosions, etc., and achieve high product quality, low ignition time, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Preparation of laser direct detonation agent powder

[0028] Take 1.0g of the prepared silver-based cationic energetic metal-organic framework [Ag(ATCA)ClO 4 ] n Mixed with 50mg of molybdenum disulfide, and ground into 100um powder material;

[0029] Step 2: Charging and packaging of laser direct detonation agent powder

[0030] The prepared laser direct detonation powder is divided into two times and pressed into the detonator. The lower 500mg powder is pressed into the detonator with a pressure of 30MP, and the pressure is kept for 5min before unloading; after the upper layer of 500mg is loaded, the pressure is released immediately after the pressure of 1MP. Press and seal the detonator with window glass.

[0031] Step 3: Laser initiation performance test based on femtosecond laser

[0032] A femtosecond laser with a wavelength of 800 nm was used to test the detonation performance of the laser detonator prepared by the above method. When the frequency of ...

Embodiment 2

[0034] Step 1: Preparation of laser direct detonation agent powder

[0035] Take 1.0g of the prepared silver-based cationic energetic metal-organic framework [Ag(ATCA)ClO 4 ] n Mixed with 30mg of molybdenum disulfide, and ground into a 50um powder material;

[0036] Step 2: Charging and packaging of laser direct detonation agent powder

[0037] The prepared laser direct detonation powder is divided into two times and pressed into the detonator. The lower layer of 500mg powder is pressed into the detonator at a pressure of 20MP, and the pressure is kept for 5 minutes before the pressure is unloaded; after the upper layer of medicament is loaded with 500mg, the pressure is released immediately after the pressure of 5MP. Press and seal the detonator with window glass.

[0038] Step 3: Laser initiation performance test based on femtosecond laser

[0039] A femtosecond laser with a wavelength of 800 nm was used to test the detonation performance of the laser detonator prepared ...

Embodiment 3

[0041] Step 1: Preparation of laser direct detonation agent powder

[0042] Take 1.0g of the prepared silver-based cationic energetic metal-organic framework [Ag(ATCA)ClO 4 ] n Mixed with 20mg of molybdenum disulfide, and ground into a 300um powder material;

[0043] Step 2: Charging and packaging of laser direct detonation agent powder

[0044] Press the prepared laser direct detonation powder twice into the detonator. The lower layer of 500mg powder is pressed into the detonator with a pressure of 35MP, and the pressure is kept for 5min before unloading; after loading the upper layer of 500mg of medicament, it is released immediately after the pressure of 2MP. Press and seal the detonator with window glass.

[0045] Step 3: Laser initiation performance test based on femtosecond laser

[0046]A femtosecond laser with a wavelength of 800 nm was used to test the detonation performance of the laser detonator prepared by the above method. When the frequency of the femtosecon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com