A barium-based energetic metal-organic framework directly detonated by 800nm laser, preparation method and application

A metal-organic framework and laser direct technology, applied in the direction of offensive equipment, igniter, detonator, etc., can solve the problems of accidental explosion, personnel and property loss, etc., and achieve the effect of low ignition time, high product quality and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

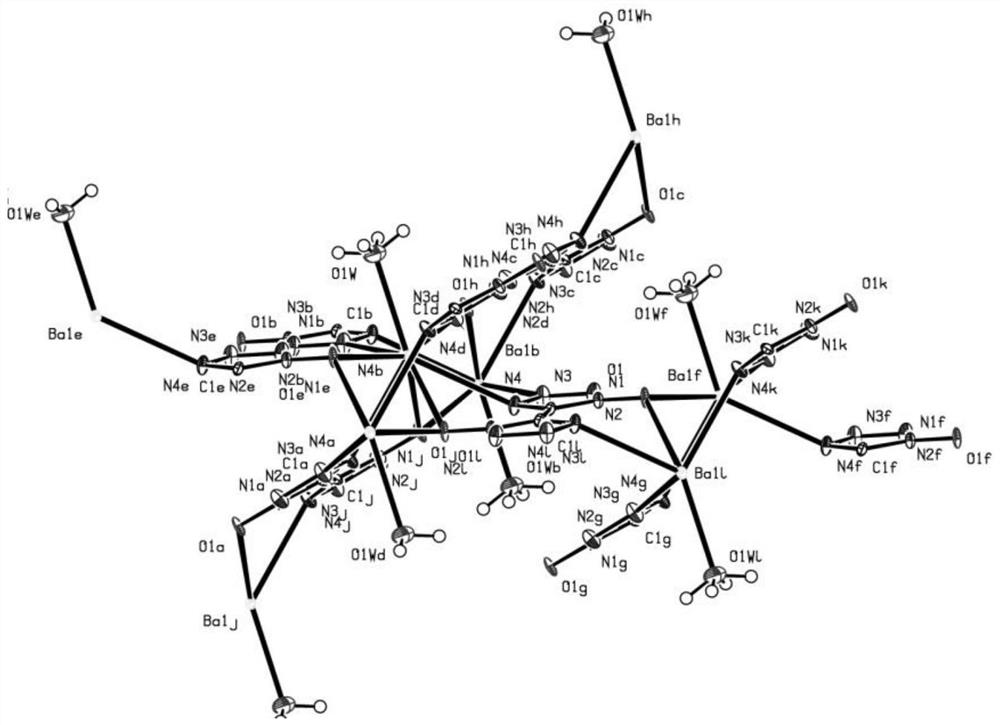

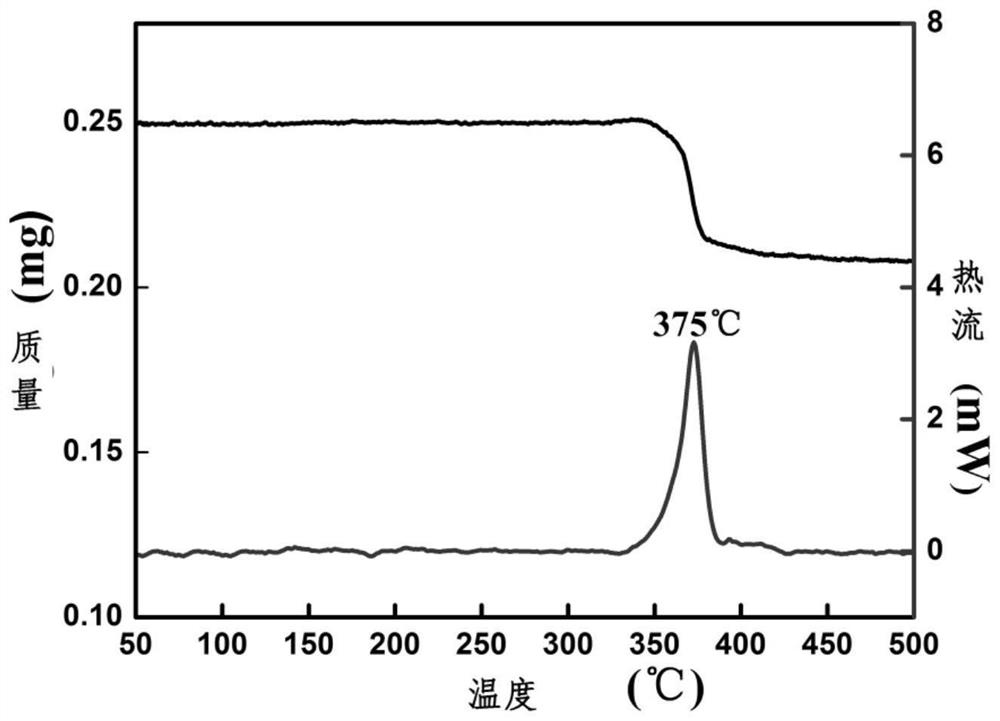

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Put 118 mg of 5,5'-bitetrazole-1,1'-dioxohydroxyammonium salt and 104 mg of barium chloride weighed into a sealable reaction kettle prepared from polytetrafluoroethylene, Add 15ml of distilled water to obtain turbid liquid;

[0024] Step 2: Seal the autoclave and place it in a pressurized steel jacket and tighten the steel jacket. and put it into a constant temperature crystal incubator;

[0025] Step 3: Set the target temperature of the constant temperature crystal incubator to 120°C, use the programmed temperature rise method to raise the temperature of the constant temperature crystal incubator to the target temperature at a heating rate of 10°C / min, keep the temperature for 48 hours, and then use the programmed cooling method to 3°C / min to return the temperature to room temperature. Using a hydrothermal method with a higher temperature, the ligand and the metal ion can react as quickly and completely as possible to obtain high-yield and high-purity crysta...

Embodiment 2

[0032] Step 1: Put 118 mg of 5,5'-bitetrazole-1,1'-dioxohydroxyammonium salt and 130 mg of barium nitrate weighed into a sealable reaction kettle made of polytetrafluoroethylene, add 10ml distilled water to obtain turbid liquid;

[0033] Step 2: Seal the autoclave and place it in a pressurized steel jacket and tighten the steel jacket. and put it into a constant temperature crystal incubator;

[0034] Step 3: Set the target temperature of the constant temperature crystal incubator to 140°C, use the programmed temperature rise method to raise the temperature of the constant temperature crystal incubator to the target temperature at a heating rate of 10°C / min, keep the temperature for 48 hours, and then use the programmed cooling method to 3°C / min to return the temperature to room temperature.

[0035] Step 4: When the temperature of the incubator drops to room temperature, the reaction kettle can be opened, and the colorless and transparent crystals in the liquid can be obse...

Embodiment 3

[0041] Step 1: Put the weighed 236 mg of 5,5'-bitetrazole-1,1'-dioxyhydroxyammonium salt and 261 mg of barium nitrate into a sealable reaction kettle made of polytetrafluoroethylene, add 30ml distilled water to obtain turbid liquid;

[0042] Step 2: Seal the autoclave and place it in a pressurized steel jacket and tighten the steel jacket. and put it into a constant temperature crystal incubator;

[0043] Step 3: Set the target temperature of the constant temperature crystal incubator to 150°C, use the programmed temperature rise method to raise the temperature of the constant temperature crystal incubator to the target temperature at a heating rate of 10°C / min, keep the temperature for 48 hours, and then use the programmed cooling method to 3°C / min to return the temperature to room temperature.

[0044] Step 4: When the temperature of the incubator drops to room temperature, the reaction kettle can be opened, and the colorless and transparent crystals in the liquid can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com