Treatment process for tannery wastewater

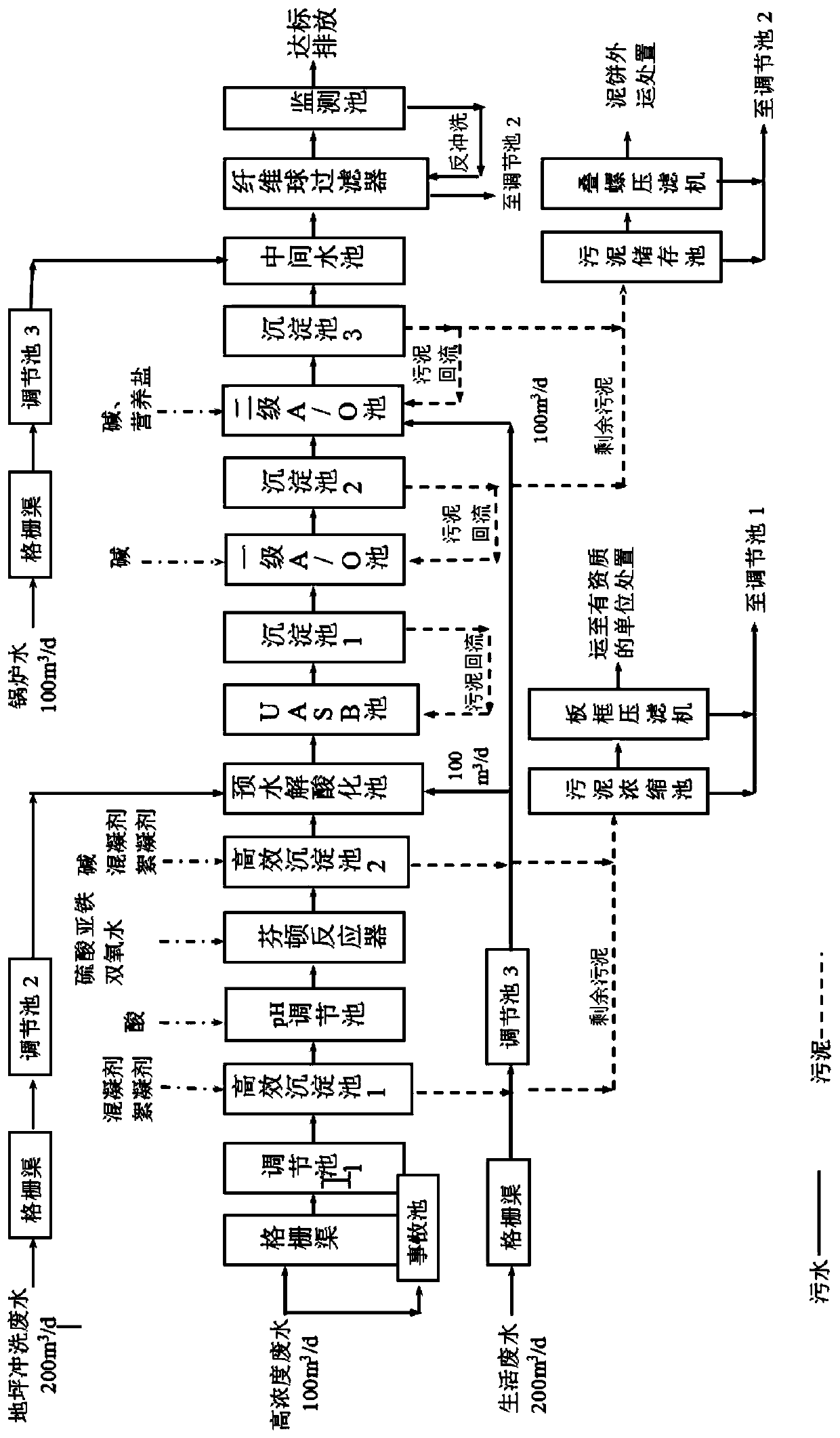

A technology for treating process and tannery wastewater, which is applied in animal processing wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of large differences in wastewater quality and quantity, drastic changes in comprehensive water quality and quantity, and inability to guarantee synchronization, etc. problems, to achieve the effect of improving biochemical reaction efficiency, low processing cost, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

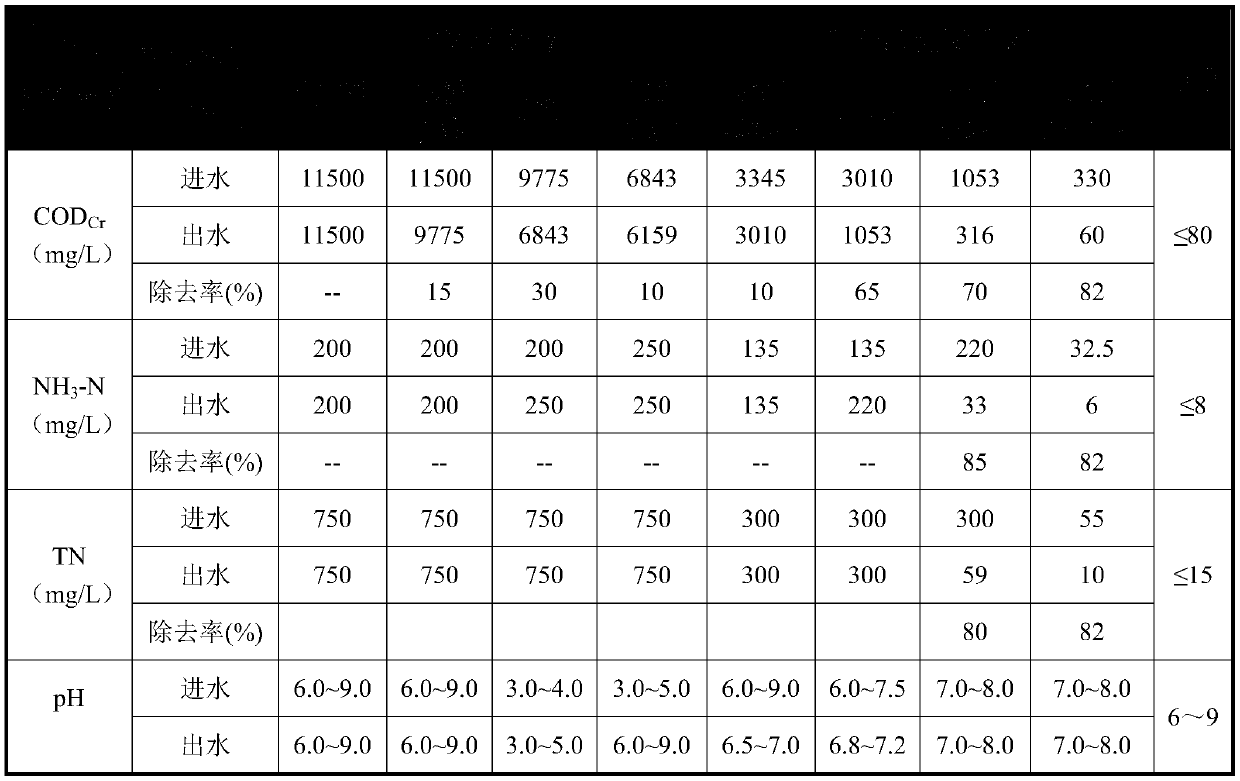

[0025] See Table 1 for the influent water quality of the project.

[0026] Table 1 Water volume and water quality of tannery wastewater generated by the project Unit: mg / L (except pH)

[0027]

[0028] After the wastewater treatment of this project, the effluent will implement the standard of "Discharge Standard of Pollutants for Synthetic Leather and Artificial Leather Industry" (GB21902-2008), and the specific design indicators are shown in Table 2.

[0029] Table 2 Design water quality Unit: mg / L (except pH and chroma)

[0030] pollution project COD cr

TN TP DMF SS NH 3 -N

pH Chroma Concentration of pollutants ≤80 ≤15.0 ≤1.0 ≤2.0 ≤40 ≤8.0 6~9 50

[0031] The specific treatment process includes the following steps:

[0032] (1) The high-concentration wastewater composed of tower washing water, condensation water, tanning water and bucket washing water flows into the grid channel through gravity, and the grid channel is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com