Composite profile and preparation method thereof

A technology of composite profile and molding process, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of high wear resistance and high strength, and achieve good cleanliness, durability Good grinding performance, inhibiting surface bacteria reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

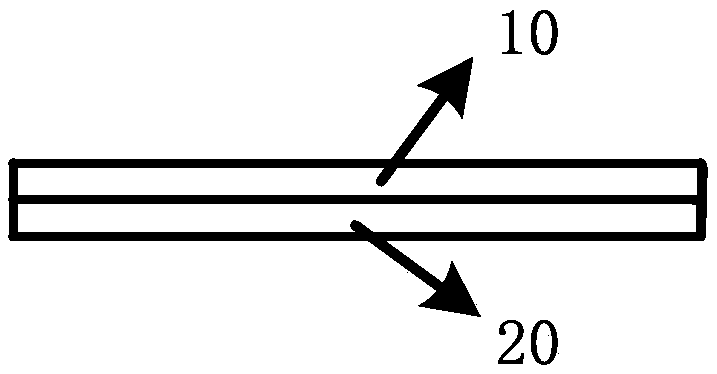

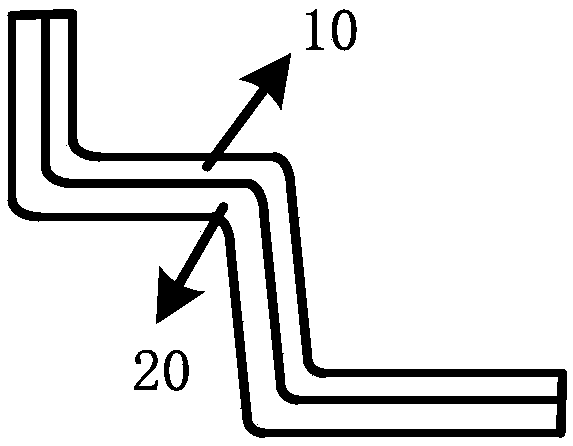

[0038] According to another aspect of the present invention, there is also provided a method for preparing the above-mentioned composite profile, comprising the following steps: forming a resin surface layer 10 from a first raw material comprising ABS resin by a first molding process; forming a resin surface layer 10 by a second molding process One side of 10 forms a resin inner layer 20, the second material forming the resin inner layer 20 includes at least one thermoplastic resin other than ABS resin, and the first material and / or the second material also includes an antibacterial agent.

[0039] In the above preparation method, the laminated resin surface layer 10 and the resin inner layer 20 can be formed simultaneously by vacuum forming, extrusion molding and other molding processes, or the above-mentioned first raw material used to form the resin surface layer 10 can be preformed first, Obtain a preformed product, and then mold the above-mentioned second raw material cont...

Embodiment 1

[0043] The preparation method of the composite profile provided by the present embodiment comprises:

[0044] Provide the first raw material including ABS resin and antibacterial agent, and provide the second raw material including fiber-reinforced polyethylene, wherein the antibacterial agent is powdered calcium phosphate loaded with alkyl dimethyl ammonium ions, wherein the number of carbon atoms of the alkyl group is 8, the particle size is 0.04μm.

[0045] The above-mentioned first raw material and the above-mentioned second raw material are laminated and formed, the first raw material forms a resin surface layer, the second raw material forms a resin inner layer, and the resin surface layer and the resin inner layer are laminated to form a composite profile.

[0046] The mass concentration of the antibacterial agent in the resin surface layer is 5%, and the thicknesses of the resin surface layer and the resin inner layer are both 0.4 mm.

Embodiment 2

[0048] The difference between the preparation method of the composite profile provided in this embodiment and embodiment 1 is:

[0049] Both the first raw material and the second raw material include an antibacterial agent. The antibacterial agent is a powdered titanium phosphate supported dialkyl dimethyl ammonium ion, wherein the number of carbon atoms in the alkyl group is 18, and the particle size is 20 μm. The mass concentration of the antibacterial agent is 0.1%, and the mass concentration of the antibacterial agent in the inner layer of the resin is 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com