Flexible material with self-cleaning function and preparation method and application thereof

A flexible material and self-cleaning technology, applied in the field of flexible materials, can solve problems such as affecting sound, air permeability, electrical conversion efficiency reduction, oil infiltration, etc., to achieve stable sound and air permeability, stable frequency response, Strong resistance to effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The specific steps of the preparation method of the flexible material with self-cleaning function in the present invention are as follows:

[0045] (1) Select a suitable self-cleaning solution;

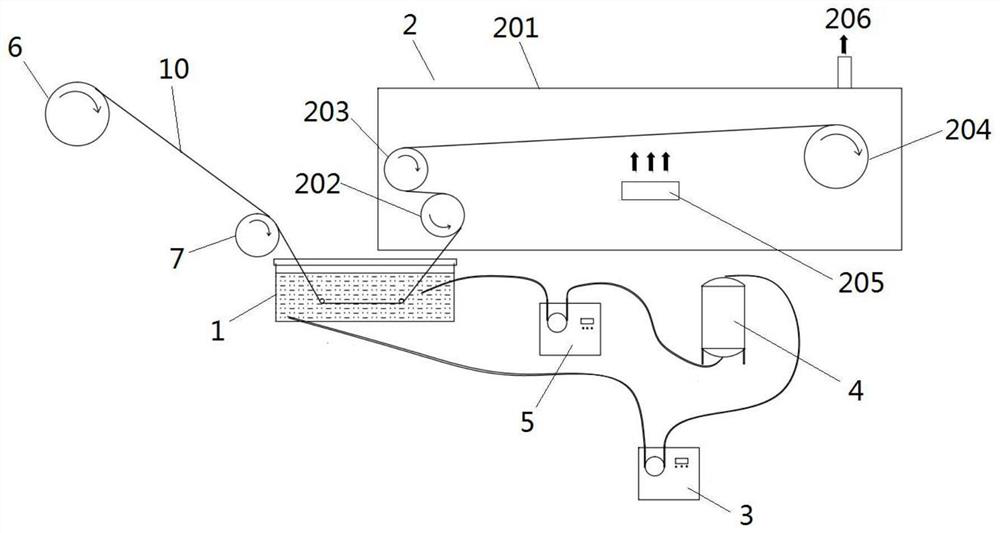

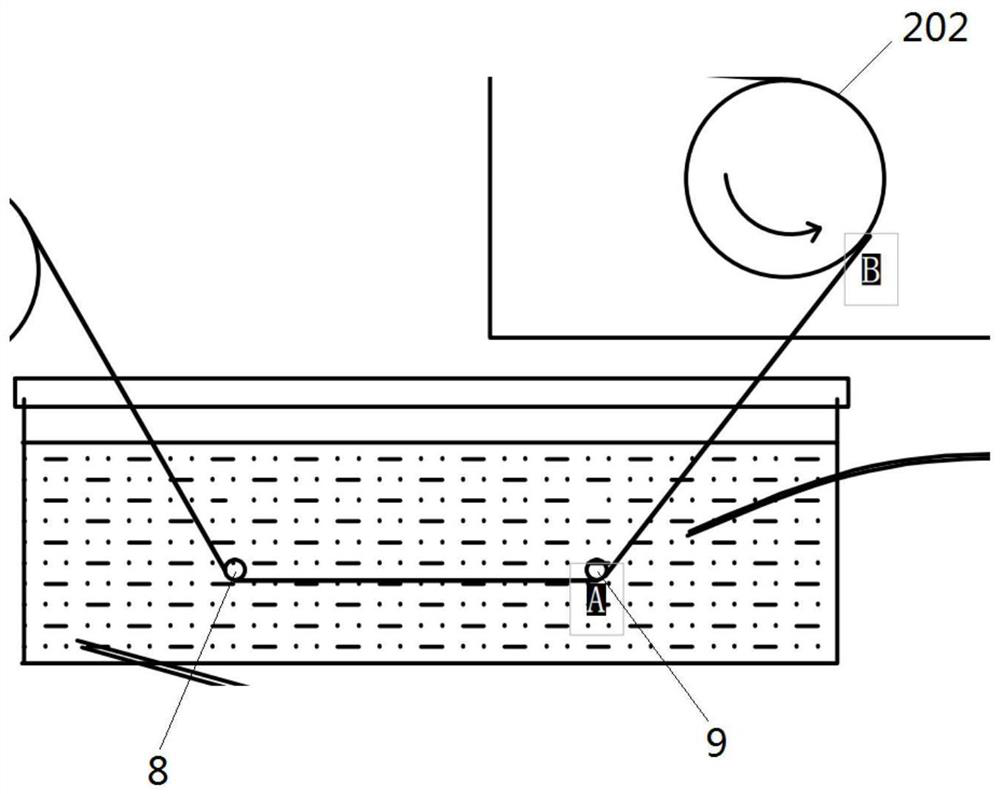

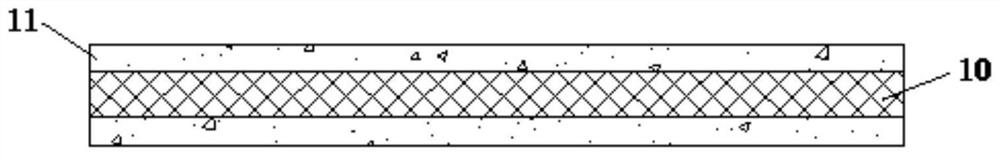

[0046] (2) Use such as figure 1 with figure 2 The self-cleaning treatment system shown performs a dip coating of the base layer 10 ( figure 1There is only one immersion pool 1 in the immersion tank 1, so it only needs to be dipped once, and when multiple immersion tanks 1 are set according to the needs, multiple dip coatings are required), during which process parameters are adjusted to perform self-cleaning treatment on the base layer 10; specifically In other words, driven by the driving shaft, the flexible material of the base layer 10 passes through the self-cleaning solution. During this process, the self-cleaning solution will adhere to the surface of the base layer 10 material and infiltrate into the internal pores of the material, forming a chimeric cross-link with t...

Embodiment 1

[0062] The fluorine-containing hydrophobic and oleophobic coating in the self-cleaning solution is selected as single-end Z-type perfluoropolyether siloxane (for the preparation method of single-end Z-type perfluoropolyether siloxane, see application number 201610551515.X, patent name It is a Chinese invention patent of "Method for preparing single-end Z-type perfluoropolyether siloxane from perfluoroiodinane", its solid content is 1wt%, and the fluorine solvent is hydrofluoroether. The antistatic agent is an ethoxylated alkylamine with a solid content of 1 wt%. The fluorine solvent is hydrofluoroether. Put the above self-cleaning solution in the soaking tank 1, the liquid level is 2-3cm higher than the rotating shaft in the soaking tank 1, and cover the top cover of the soaking tank 1 to reduce the volatilization loss of the fluorine solvent. Adjust the fifth guide roller 204 (the rotation axis of the fifth guide roller 204 is driven by a servo motor, so the rotation speed o...

Embodiment 2

[0064] Increase the mass fraction of perfluoropolyether siloxane and ethoxylated alkylamine in the self-cleaning solution in Example 1, and measure the oleophobicity of the self-cleaning coating layer 11 . When the mass fraction is 0.2% and 0.3%, the oleophobicity of the self-cleaning coating layer 11 reaches the best effect, and its contact angles are 67.1° and 67° respectively. The water contact angle of the self-cleaning paint layer 11 first decreases and then increases with the increase of the mass fraction, thereby increasing the self-cleaning ability of the flexible material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com