Iron oxide surface coating technology

A surface coating, iron oxide technology, applied in transportation and packaging, pressure inorganic powder coating, coating and other directions, can solve the problems of long time coating aluminum oxide film, low coating quality, heavy workload, etc. The effect of avoiding separate screening operation, good mixing effect and saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] see figure 1 , an iron oxide surface coating technology, comprising the following steps:

[0052] A1. Place 60-70 parts by weight of iron oxide powder and 30-40 parts by weight of aluminum powder in No. 1 self-selected high-speed dispersing equipment and No. 2 self-selected high-speed dispersing equipment:

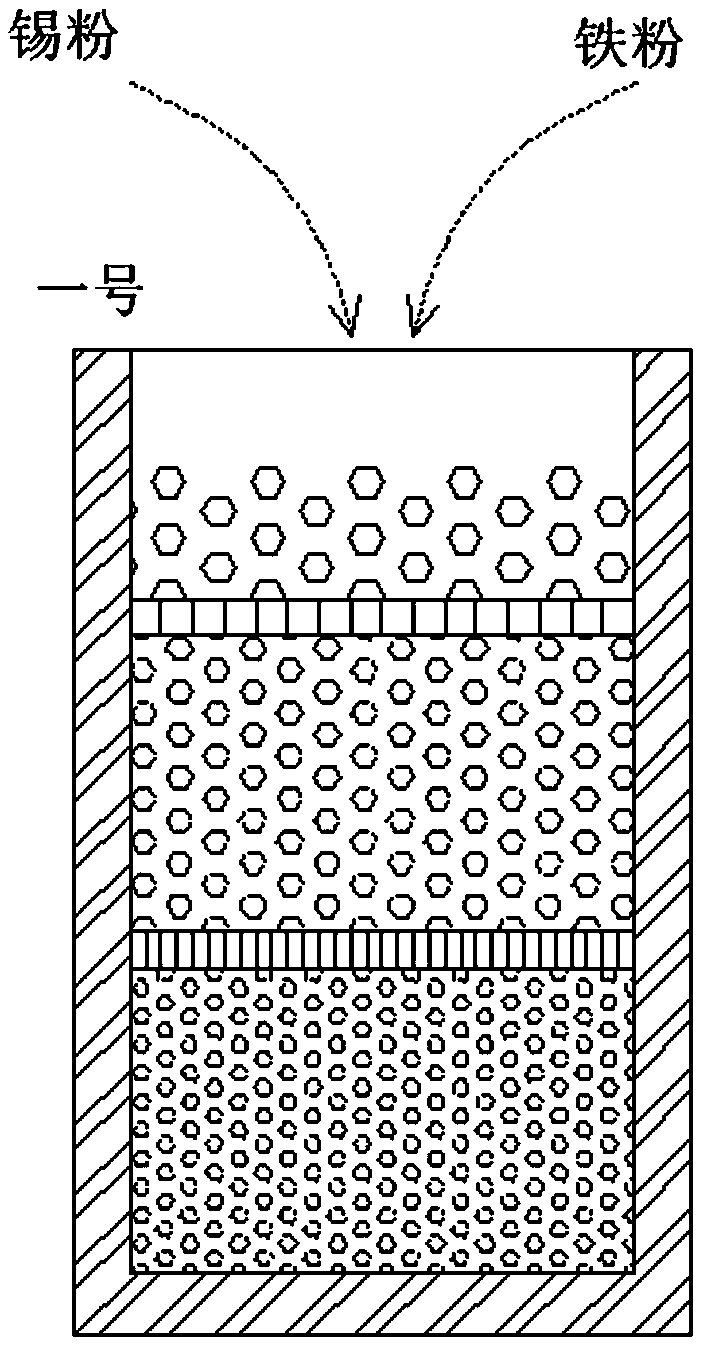

[0053] a. Please refer to image 3 , the iron oxide powder is heated and dispersed at a high speed in No. 1 optional high-speed dispersing equipment, and the dispersion time is 5-15 minutes. Tin powder is completely melted and coated on the surface of iron oxide powder to obtain tin layer iron powder;

[0054] b. Please refer to Figure 4 , the aluminum powder is heated and dispersed at a high speed in No. 2 optional high-speed dispersing equipment. The dispersion time is 5-15 minutes. Completely melted and coated on the surface of aluminum powder to obtain tin layer aluminum powder;

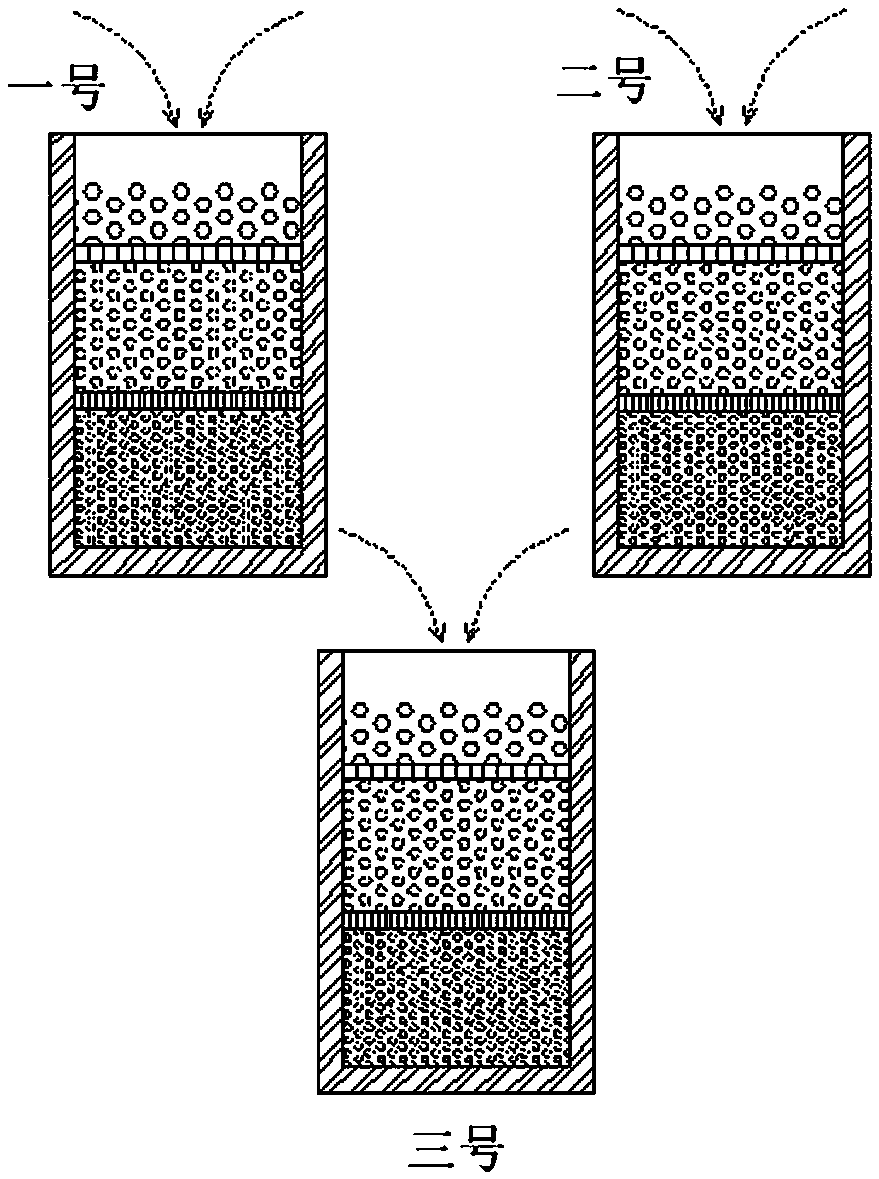

[0055] A2. Please refer to Figure 5 Put the tin layer iron powder in the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com