High-reflection film for 10 kW semiconductor laser and preparation method thereof

A high-reflection film and laser technology, applied in the field of optical reflective films, can solve the problems of increasing the difficulty of film thickness monitoring, increasing the number of film layers, and increasing the cost of coating, so as to improve the ability to resist laser damage and reduce the number of film layers. number, the effect of reducing the plating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the high reflection film provided by the invention comprises the following steps:

[0033] S1. cleaning the substrate;

[0034] S2. Clean the reaction chamber, place the substrate and the coating material in the coating equipment, and vacuumize to 10 -4 Below Pa;

[0035] S3. Set the control program of the coating equipment, and prepare TiO on the substrate in turn 2 - SiO 2 Membranes and HfO 2 - SiO 2 Membrane stack, and coated with HfO on the outermost layer 2 film layer;

[0036] Among them, the TiO 2 For the film layer, the substrate temperature is 280-350°C; 2 For the film layer, the substrate temperature is 200-260°C; HfO plating 2 For the film layer, the substrate temperature is 380-430°C;

[0037] S4. Annealing the plated film in situ at 300-400° C. for 20-60 min to prepare the high-reflection film.

[0038] What the substrate of the present invention adopts is K9 glass, and its anti-laser damage property is better than SiO ...

Embodiment 1

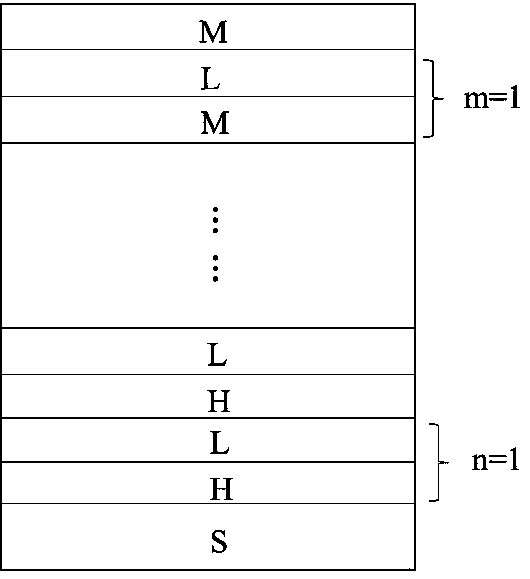

[0043] A high-reflection film for a 10kW semiconductor laser is characterized in that it includes a substrate and an optical film system attached to the substrate, and its characteristic structure is S / (HL) 10 (ML) 3 M / Air, where S means K9 glass, H means TiO with high refractive index 2 film layer, L means SiO with low refractive index 2 film layer, M indicates HfO with high damage threshold 2 film layer; the high reflection film is a laser high reflection film with a working wavelength λ of 1064 nm, and the preparation method is as follows:

[0044] S1. The substrate is cleaned, and on the ultra-clean bench, use a non-woven cloth dipped in a mixed solution of alcohol and ether (mixing ratio 3:1) to clean the substrate, and then dry it;

[0045] S2. Fully clean the reaction chamber, keep the equipment with a high degree of cleanliness, place the cleaned substrate and coating material in the ion beam-assisted deposition coating equipment, and vacuum to 10 -4 Below Pa;

[...

Embodiment 2-8

[0055] Embodiment 2-8 is compared with embodiment 1, and difference is that described TiO 2 - SiO 2 Films and HfO 2 - SiO 2 The period number of the film system is shown in Table 1, and the others are the same as in Example 1. Table 1 also shows the reflectivity and anti-laser damage threshold of the high-reflection film prepared in Example 2-5 at λ = 1064 nm.

[0056] It can be seen from the test results in Table 1 that when HfO 2 - SiO 2 When the period of the film system is constant, as the TiO 2 - SiO 2 The period number of the film system increases, the reflectivity of the high-reflection film increases, but the damage threshold decreases, because the high refractive index of TiO 2 The number of film layers increases, so the reflectivity increases, but as the number of film layers increases, the HfO 2 The relative thickness of the number of film layers is reduced, so the anti-laser damage threshold is reduced, and TiO 2 - SiO 2 When the period number of the film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com