Anti-arc ablation material and preparation method and application thereof

An ablation material, anti-arc technology, applied in circuits, electrical switches, electrical components, etc., can solve the problems of contact resistance and mechanical wear performance not meeting the requirements of use well, and achieve improved wettability and contact resistance, The effect of improving strength and toughness and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

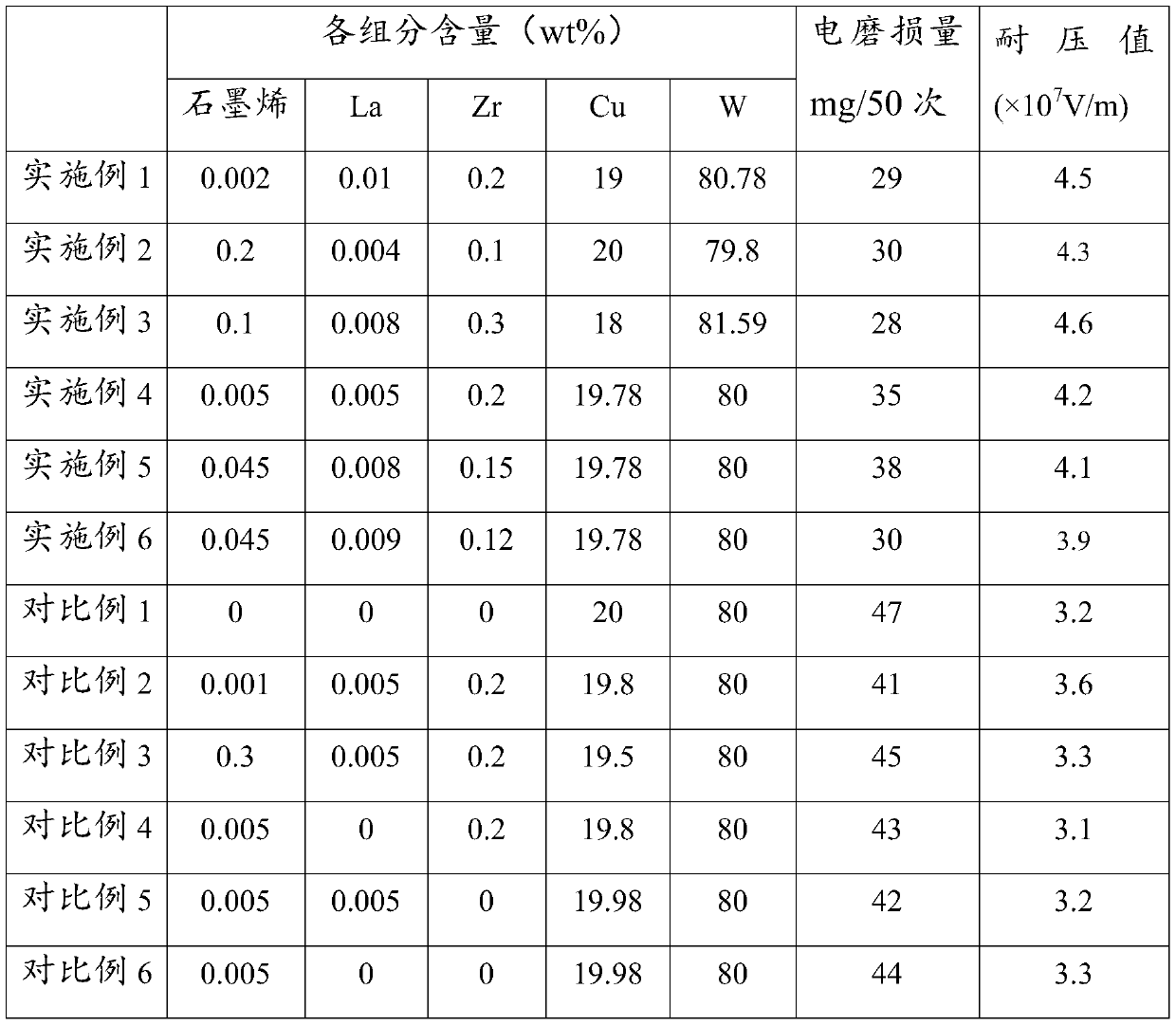

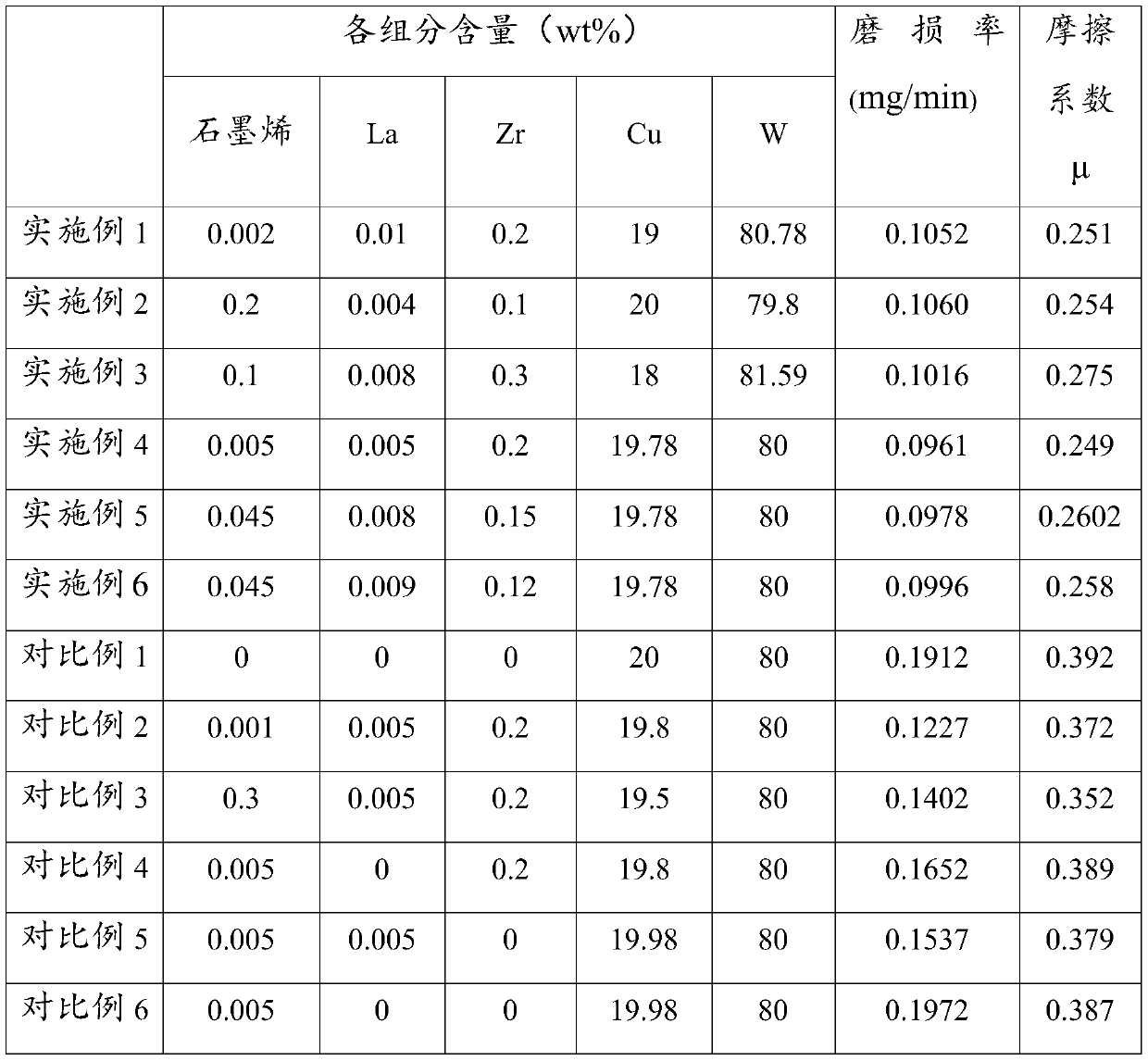

Examples

Embodiment 1

[0037] This embodiment provides an anti-arc ablation material and its preparation method, the specific steps are:

[0038]Mixing of raw materials: Weigh 0.002g of graphene and add it into 0.2ml of ethanol to obtain a 10mg / ml graphene ethanol suspension, then mix it with 0.2ml of 0.5M polyvinyl butyral ethanol solution, and gradually add it under the condition of stirring at 8000rpm 80.78g tungsten powder, 0.01g lanthanum, 0.2g zirconium and 9.5g copper powder to obtain mixed powder;

[0039] Compact: vacuum-dry the mixed powder, pass through an 80-mesh sieve, and press into a steel mold with a pressing pressure of 500 MPa to obtain a compact;

[0040] Sintering: Heat the green compact to 185°C in an argon protection furnace and keep it for 30 minutes; then raise the temperature to 450°C and keep it for 30 minutes; then raise the temperature to 1400°C for sintering, keep it for 1.5 hours, and then cool it to room temperature to obtain a sintered compact;

[0041] Infiltration:...

Embodiment 2

[0043] This embodiment provides an anti-arc ablation material and its preparation method, the specific steps are:

[0044] Mixing of raw materials: Weigh 0.2g of graphene oxide and add it to 8ml of ethanol to obtain a 25mg / ml graphene ethanol suspension, then mix it with 16ml of 0.6M polyvinyl butyral ethanol solution, and gradually add 79.8 g tungsten powder, 0.004g lanthanum, 0.1g zirconium and 6g copper powder to obtain mixed powder;

[0045] Compact: the mixed powder is vacuum-dried, passed through a 90-mesh sieve, and pressed into a steel mold with a pressing pressure of 700 MPa to obtain a compact;

[0046] Sintering: Heat the green compact to 180°C in an argon protection furnace and keep it for 50 minutes; then raise the temperature to 400°C and keep it for 50 minutes; then raise the temperature to 1500°C for sintering, keep it for 2.5 hours, and then cool it to room temperature to obtain a sintered billet;

[0047] Infiltration: After cleaning the surface of the sinte...

Embodiment 3

[0049] This embodiment provides an anti-arc ablation material and its preparation method, the specific steps are:

[0050] Raw material mixing: Weigh 0.1g of reduced graphene oxide and add it to 5ml of ethanol to obtain a 20mg / ml graphene ethanol suspension, then mix it with 2.5ml of 0.4M polyvinyl butyral ethanol solution, and gradually Add 81.59g of tungsten powder, 0.008g of lanthanum, 0.3g of zirconium and 7.2g of copper powder to obtain a mixed powder;

[0051] Compact: vacuum-dry the mixed powder, pass through a 100-mesh sieve, and press into a steel mold with a pressing pressure of 600 MPa to obtain a compact;

[0052] Sintering: Heat the green compact to 175°C in an argon protection furnace and keep it for 40 minutes; then raise the temperature to 500°C and keep it for 40 minutes; then raise the temperature to 1400°C for sintering, keep it for 2 hours, and then cool it down to room temperature to get a sintered billet;

[0053] Infiltration: After cleaning the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com