Synthesis method of environmentally-friendly vehicle biodiesel

A technology of biodiesel and synthesis method, applied in the direction of biofuel, chemical instrument and method, organic compound/hydride/coordination complex catalyst, etc., can solve the problem of no recyclability, etc., and achieve easy recovery and high catalysis Good performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In one embodiment, the preparation method of transesterification catalyst comprises the steps:

[0037] Deashed lignin is obtained by removing ash from lignin through acid pretreatment; the ash in lignin promotes the release of volatile matter during the carbonization process, so that the yield of activated carbon is relatively low, and acid pretreatment lignin can effectively remove Inorganic salt ash in lignin;

[0038] Mix deashed lignin with activator and then knead to obtain kneaded lignin;

[0039] Carbonize the kneaded lignin to obtain activated carbon particles;

[0040] Add anhydrous toluene and silane coupling agent to the activated carbon, and reflux to obtain modified activated carbon particles; avoid the presence of water during this process;

[0041] Phosphorous acid is added to the modified active carbon, reflux reaction, and formaldehyde solution is added dropwise to obtain a transesterification catalyst.

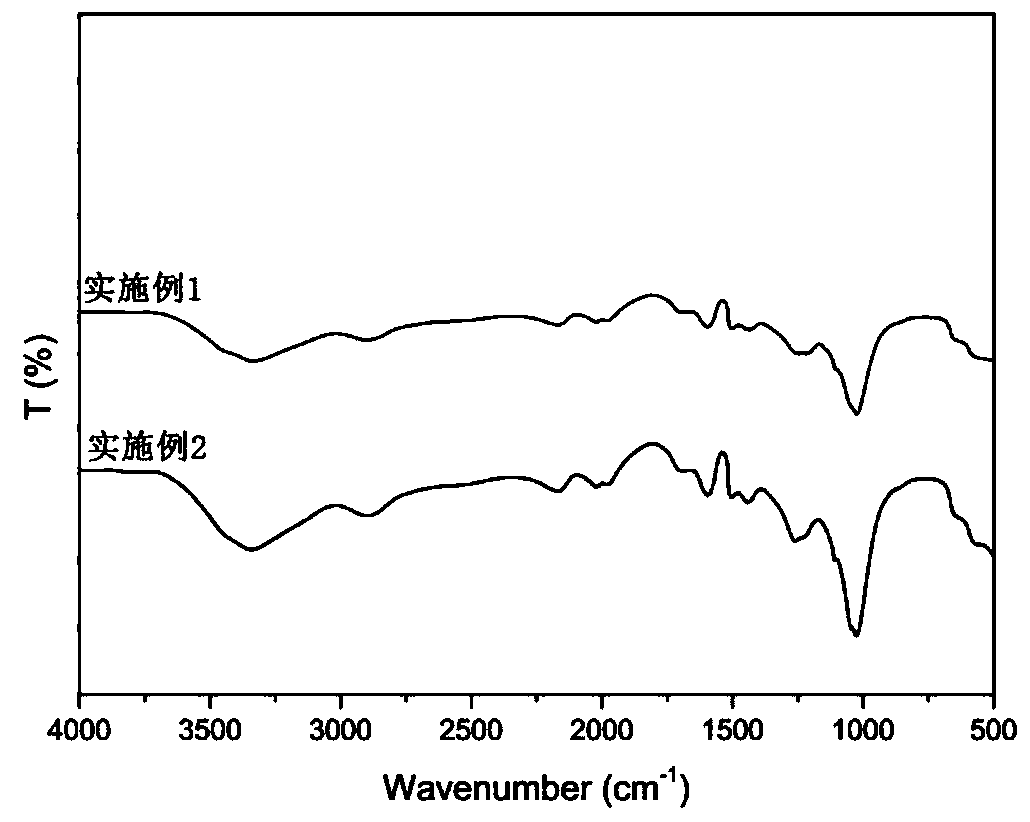

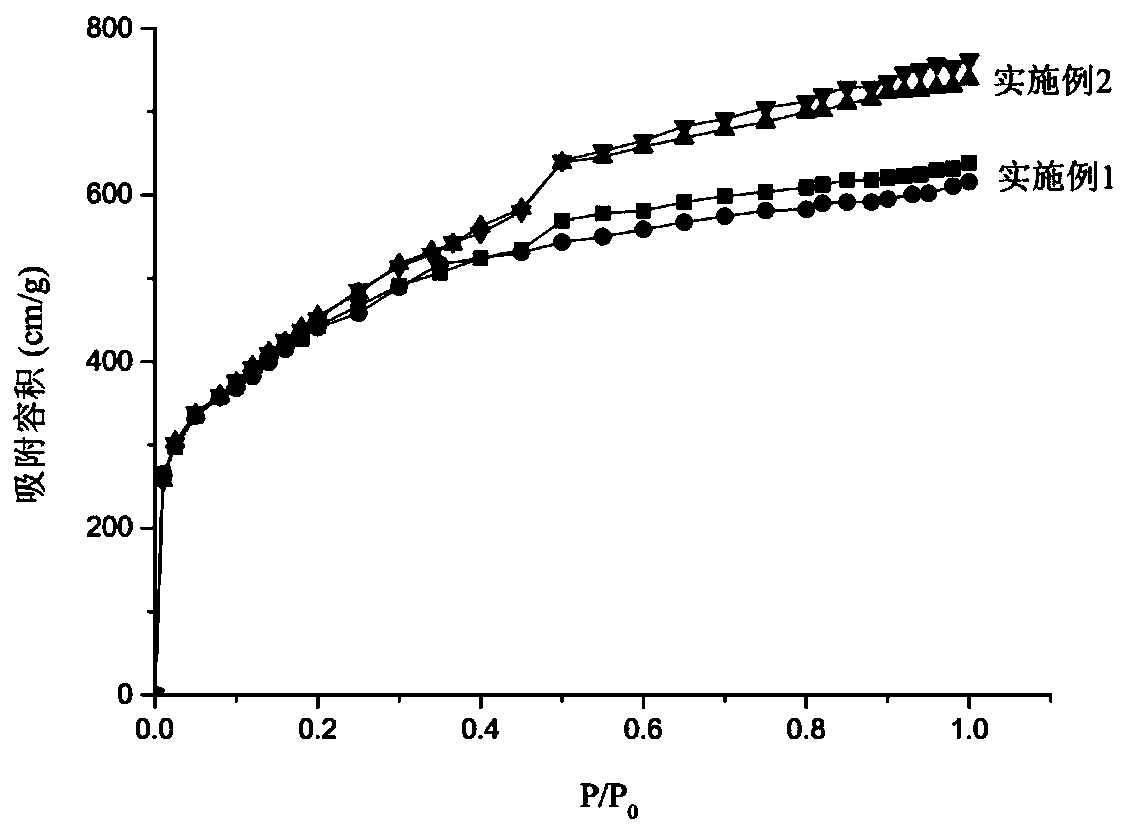

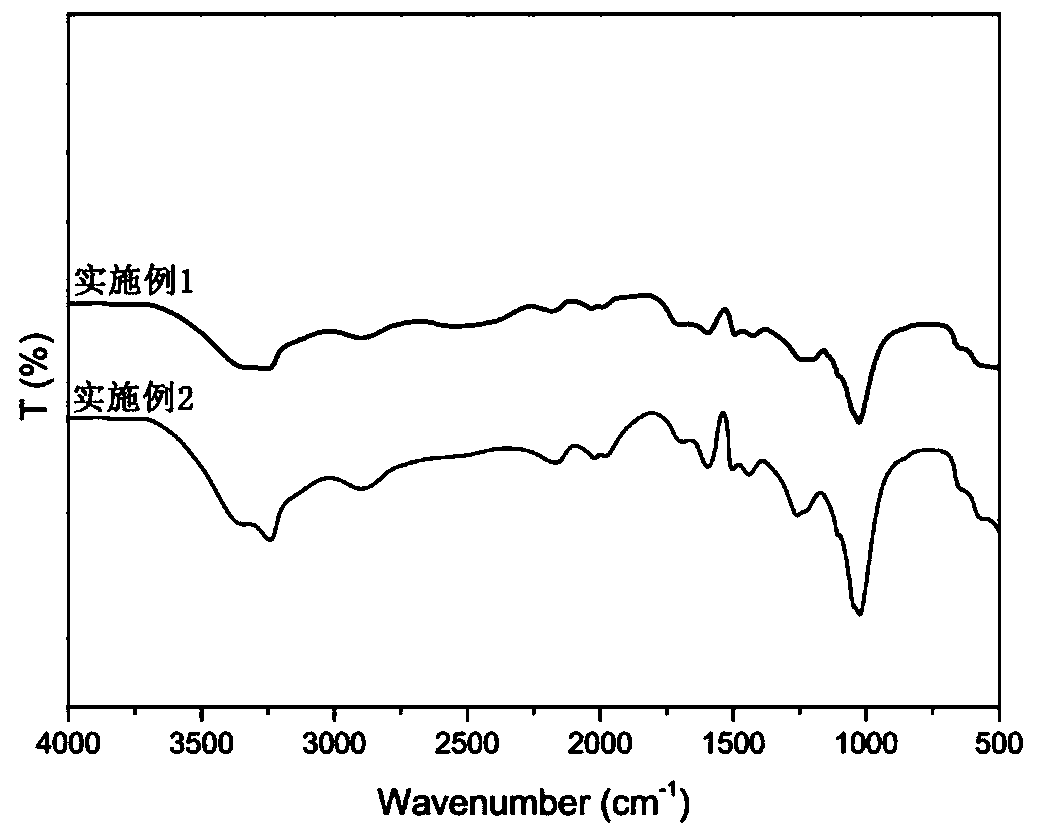

[0042]In this preparation method, the obtain...

Embodiment 1

[0059] The preparation method of transesterification catalyst comprises the steps:

[0060] S1: Dissolve lignin in deionized water at a solid-to-liquid ratio of 1:5g / mL, add concentrated sulfuric acid during stirring to make the pH 1.5, continue stirring at 80°C for 5 hours, remove ash, centrifuge and wash until the pH is low Change and dry to obtain deashed lignin;

[0061] S2: Add phosphoric acid to the delimed lignin obtained in step S1 at a solid-to-liquid ratio of 1:4g / mL, mix thoroughly, and knead at 150°C for 45 minutes to obtain kneaded lignin;

[0062] S3: Put the kneaded lignin obtained in step S2 at a temperature of 550°C and N 2 Carry out carbonization and activation at the same time at a flow rate of 80mL / min for 3 hours, wash until the washing water is close to neutral, and dry to obtain activated carbon particles;

[0063] S4: According to the solid-to-liquid ratio of 1:3g / mL, add anhydrous toluene to the activated carbon obtained in step S3, and then add a si...

Embodiment 2

[0066] The preparation method of transesterification catalyst comprises the steps:

[0067] S1: Dissolve lignin in deionized water at a solid-to-liquid ratio of 1:5g / mL, add concentrated sulfuric acid during stirring to make the pH 1.5, continue stirring at 80°C for 5 hours, remove ash, centrifuge and wash until the pH is low Change and dry to obtain deashed lignin;

[0068] S2: Add phosphoric acid to the delimed lignin obtained in step S1 at a solid-to-liquid ratio of 1:4g / mL, then add polyethylene glycol with 0.3% by weight of phosphoric acid and sodium hypophosphite with 0.02% by weight of phosphoric acid, mix thoroughly, and Kneading at 150°C for 45 minutes to obtain kneading lignin, polyethylene glycol and sodium hypophosphite;

[0069] S3: Put the kneaded lignin obtained in step S2 at a temperature of 550°C and N 2 Carry out carbonization and activation at the same time at a flow rate of 80mL / min for 3 hours, wash until the washing water is close to neutral, and dry to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com