Coupling membrane biological treatment reactor for toxic high-nitrogen-content chemical industry sewage

A technology of biological treatment and nitrogen chemical industry, applied in biological treatment devices, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor anti-pollutant impact ability, failure of effluent total nitrogen to reach the standard, and poor system operation Stability and other issues, to achieve the effect of reducing the toxicity of sewage, increasing energy consumption, and stabilizing the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A wet-process acrylic fiber production sewage, the treatment capacity is 150m 3 / h, water quality after neutralization and coagulation air flotation to remove suspended solids: COD: 1000mg / L, total nitrogen: 115mg / L, ammonia nitrogen: 15mg / L, acrylonitrile: 80mg / L, sodium thiocyanate: 100mg / L.

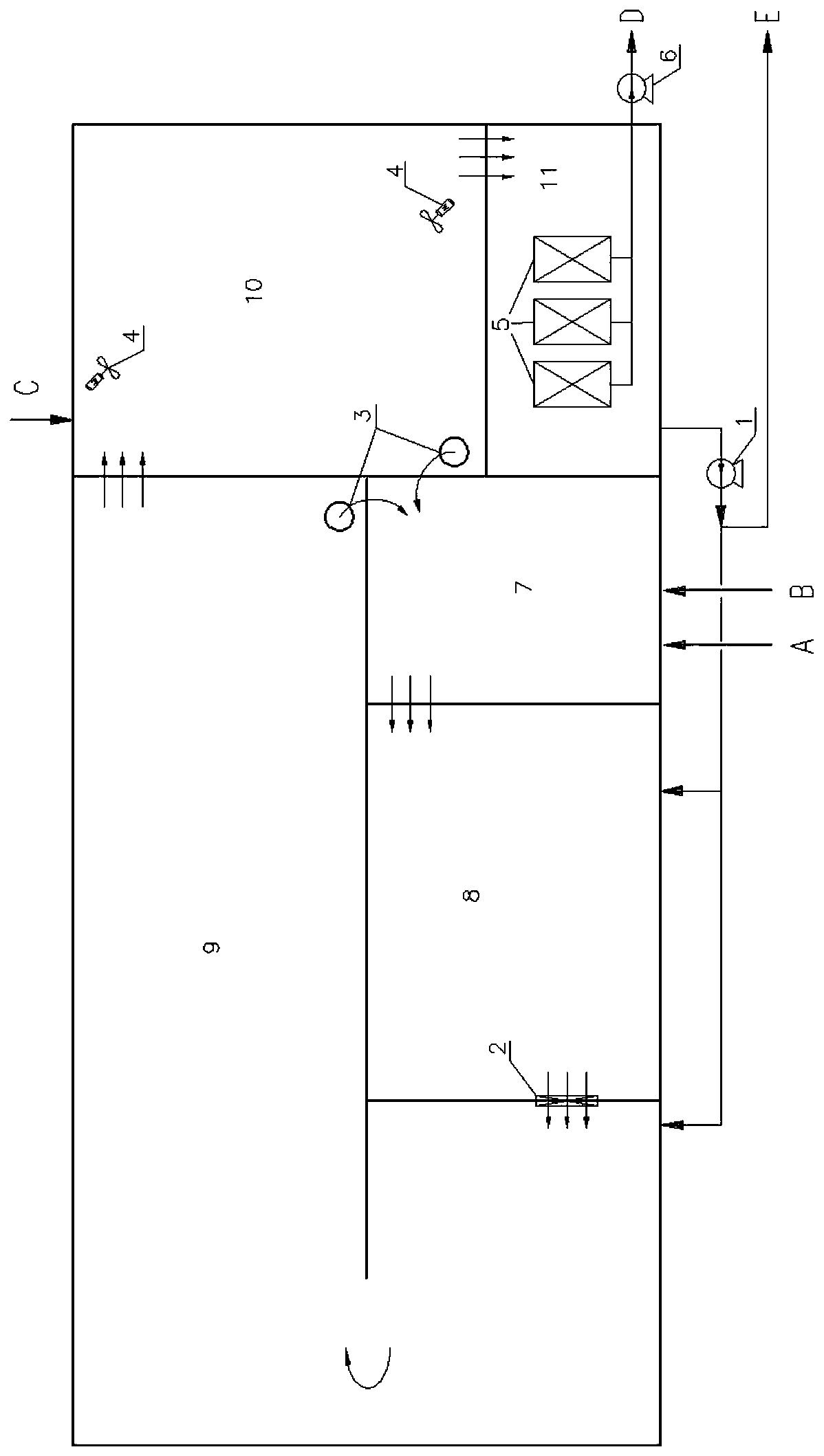

[0053] The treatment process and reactor structure are as follows figure 1 As shown, the coupled membrane bioreactor (CCMBR) used is a reinforced concrete structure.

[0054] Suspended packing oxidation tank, aerobic activated sludge tank, anoxic activated sludge tank and membrane tank were inoculated and acclimatized with sludge for 2 to 4 weeks respectively, and the acrylic fiber wastewater entered biological selection tank, suspended packing oxidation tank, aerobic Activated sludge tank, anoxic activated sludge tank and membrane tank, the final effluent is pumped from the ultrafiltration membrane module of the membrane tank.

[0055] The biological selection tank is used ...

Embodiment 2

[0065] An acrylonitrile plant produces sewage with a treatment capacity of 50m 3 / h, the influent water quality is COD:

[0066] 3500mg / L, total nitrogen: 280mg / L, ammonia nitrogen: 80mg / L, NO 3 - -N: 12 mg / l, acrylonitrile: 100 mg / L, pyridines: 600 mg / L.

[0067] The treatment process and reactor structure are as follows figure 1 As shown, the coupled membrane bioreactor (CCMBR) used is a reinforced concrete structure.

[0068] Suspended packing oxidation tank, aerobic activated sludge tank, anoxic activated sludge tank and membrane tank were respectively inoculated and domesticated with sludge for 2 to 4 weeks, and the acrylonitrile sewage entered the biological selection tank, suspended packing oxidation tank, good Oxygen activated sludge tank, anoxic activated sludge tank and membrane tank, the final effluent is pumped from the ultrafiltration membrane module of the membrane tank.

[0069] The biological selection tank is used as a hydrolysis and acidification tank. T...

Embodiment 3

[0079] A coking waste water with a treatment capacity of 100m 3 / h, after dephenolization, ammonia distillation, decyanation and pre-recovery of phenol sodium salt, liquid ammonia and cyanide, the sewage water quality is COD: 3000mg / L, ammonia nitrogen: 300mg / L, phenol: 300mg / L, cyanide: less than 20mg / L.

[0080] The treatment process and reactor structure are as follows figure 1 As shown, the coupled membrane bioreactor (CCMBR) used is a reinforced concrete structure.

[0081] Suspended packing oxidation tank, aerobic activated sludge tank, anoxic activated sludge tank and membrane tank were inoculated and acclimatized with sludge for 2 to 4 weeks respectively, and the acrylic fiber wastewater entered biological selection tank, suspended packing oxidation tank, aerobic Activated sludge tank, anoxic activated sludge tank and membrane tank, the final effluent is pumped from the ultrafiltration membrane module of the membrane tank.

[0082] The biological selection tank is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com