Caustic soda-free and normal temperature papermaking pulping process

A technology of pulping and normal temperature, which is applied in the field of paper pulping, can solve the problems of large energy consumption in coal combustion, resource and energy consumption, backward pulping process, etc., achieve low production cost, less labor, and improve pulp yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following description describes alternative embodiments of the invention to teach those of ordinary skill in the art how to make and reproduce the invention.

[0042] Embodiments of the present invention are as follows, and embodiment is raw material with cotton stalk.

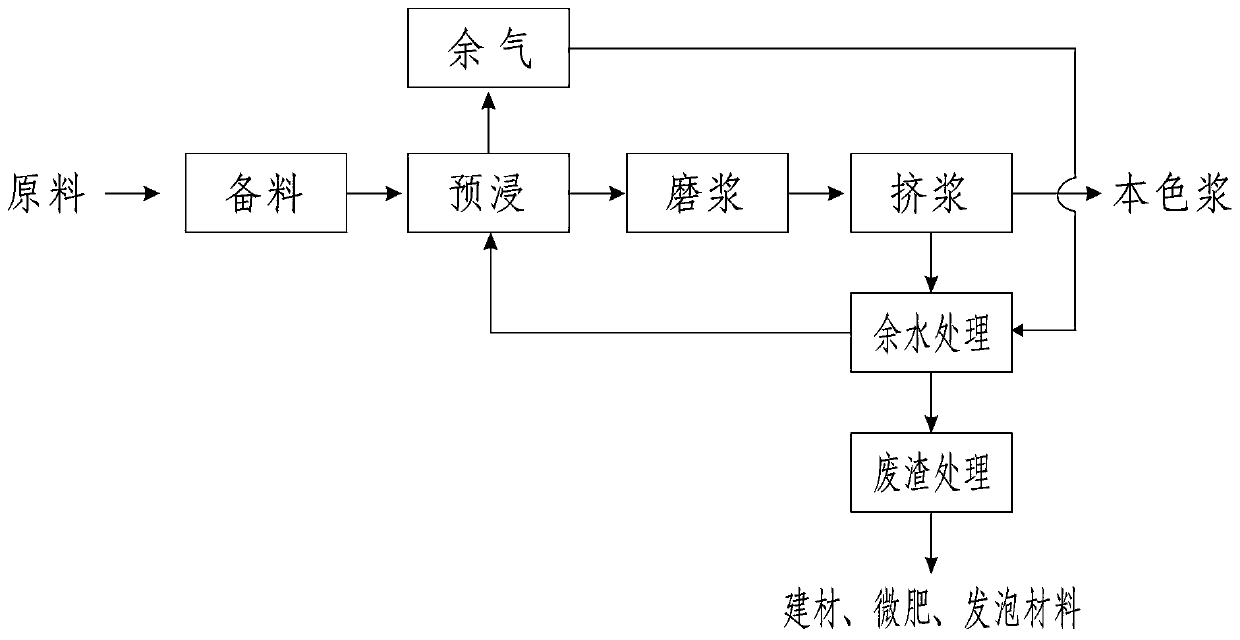

[0043] A new papermaking pulping process without caustic soda at room temperature, the pulping process is shown in Figure 1 ,

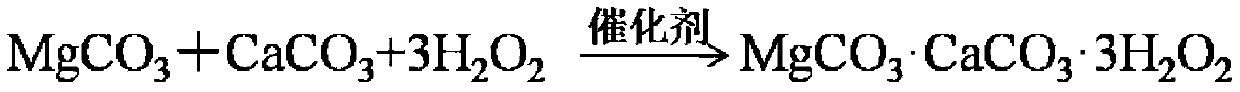

[0044] 1. The non-caustic soda normal temperature pulping formula includes:

[0045] Environmentally friendly pulping agent A

[0046] Environmentally friendly pulping agent B

[0047] 2. Pulping equipment includes:

[0048] Material preparation: BX215 drum chipper

[0049] Prepreg: self-made silo, 304# material

[0050] Refining: YZJH350 high concentration refining machine

[0051] Squeezing: RBYL-1000 belt filter press

[0052] Remaining water treatment pool: self-made, 304# material

[0053] Waste residue treatment pool: self-made, 304# material

[0054] 3. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com