Epoxy resin adhesive composition for multilayer flexible circuit board, preparation method of epoxy resin adhesive composition, and adhesive film

A flexible circuit board and epoxy resin technology, applied in the direction of epoxy resin glue, film/sheet adhesive, adhesive type, etc., can solve problems such as poor operation, low initial adhesion, and low efficiency , to achieve the effect of improving production efficiency, product yield and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

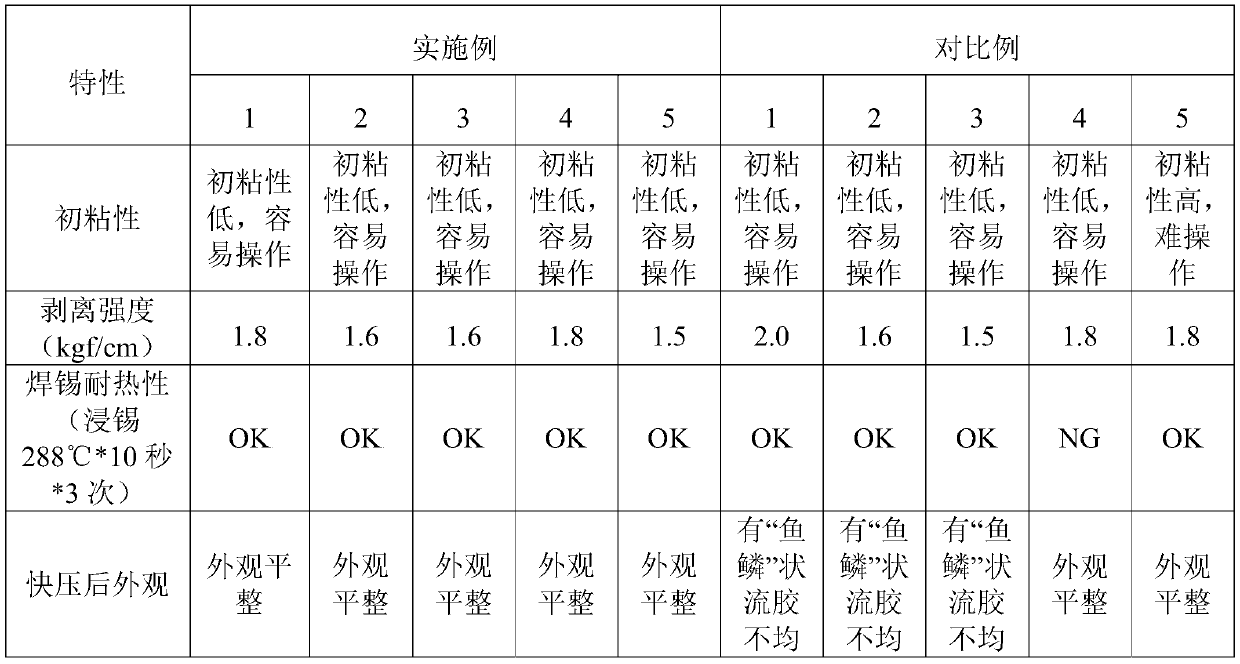

Examples

Embodiment 1

[0044]An epoxy resin bonding composition for multilayer flexible circuit boards, comprising the following raw materials in parts by weight:

[0045] 15 parts of high molecular weight epoxy resin, 40 parts of low water absorption epoxy resin, 18 parts of high molecular weight end carboxyl nitrile rubber, 12 parts of low molecular weight end carboxyl nitrile rubber, 12 parts of fumed silica, 3 parts of curing agent.

[0046] In the above formula, the high molecular weight epoxy resin is JER1256 high molecular weight epoxy resin, the low water absorption epoxy resin is XD-1000 epoxy resin, and the curing agent is 4,4-diaminodiphenyl sulfone.

Embodiment 2

[0048] An epoxy resin bonding composition for multilayer flexible circuit boards, comprising the following raw materials in parts by weight:

[0049] 15 parts of high molecular weight epoxy resin, 40 parts of low water absorption epoxy resin, 21 parts of high molecular weight end carboxyl nitrile rubber, 9 parts of low molecular weight end carboxyl nitrile rubber, 12 parts of fumed silica, 3 parts of curing agent.

[0050] In the above formula, the high molecular weight epoxy resin is JER1256 high molecular weight epoxy resin, the low water absorption epoxy resin is XD-1000 epoxy resin, and the curing agent is 4,4-diaminodiphenyl sulfone.

Embodiment 3

[0052] An epoxy resin bonding composition for multilayer flexible circuit boards, comprising the following raw materials in parts by weight:

[0053] 10 parts of high molecular weight epoxy resin, 45 parts of low water absorption epoxy resin, 18 parts of high molecular weight end carboxyl nitrile rubber, 12 parts of low molecular weight end carboxyl nitrile rubber, 12 parts of fumed silica, 3 parts of curing agent.

[0054] In the above formula, the high molecular weight epoxy resin is JER1256 high molecular weight epoxy resin, the low water absorption epoxy resin is XD-1000 epoxy resin, and the curing agent is 4,4-diaminodiphenyl sulfone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com