High-permeability water-borne epoxy slurry as well as preparation method and application thereof

A water-based epoxy, high-penetration technology, used in epoxy resin adhesives, adhesive types, adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

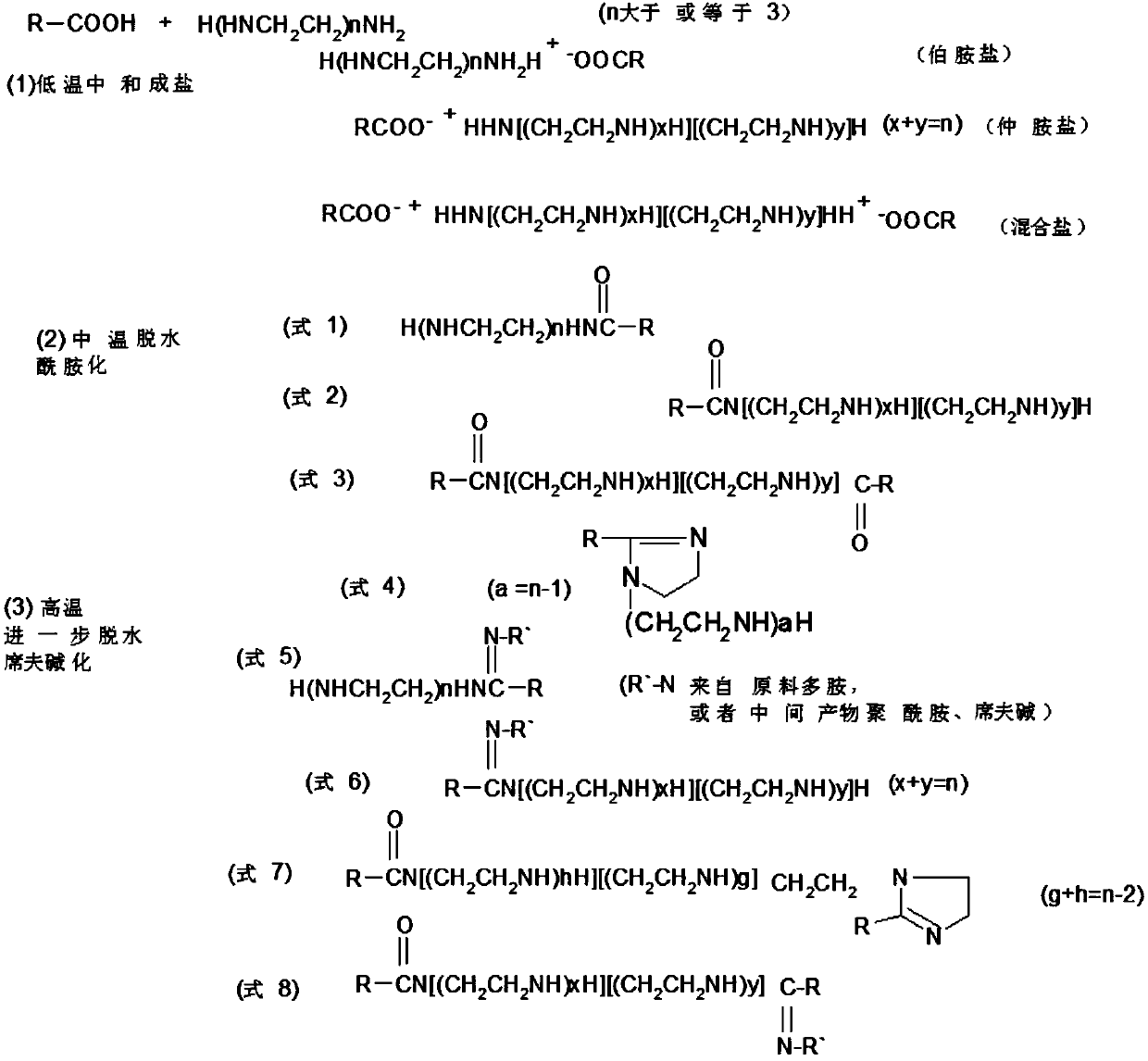

[0068] Embodiment 1: Preparation of water-based amide Schiff base complex curing agent

[0069] (1) Add 1039.5g (5.5 moles) of tetraethylenepentamine into a 5000mL three-necked flask, heat up to 50°C, and slowly add 1490g (5 moles) of ricinoleic acid (molecular weight: 298, Zibo Wanmeng Chemical Co., Ltd. Co., Ltd.), and then heated up to 140°C to 150°C for 3 hours to react, during which 88.7g of water (theoretical water output was 90g) was distilled out under no solvent, at this time, ricinoleic acid amide-amine PAM1 was obtained. Then continue to heat up to 210 ° C for 5 hours, and in this process, 80.3 g of low boiling point liquid is evaporated under no solvent (through chromatographic analysis, the water is 76.9 g, and the others are polyamines), and after cooling, the product containing amide and Schiff Aqueous amide Schiff base complex WASB1 of the base. Samples were taken, and the measured viscosities of PAM1 and WASB1 at room temperature 25°C were 380 and 90 mPa·s, r...

Embodiment 2

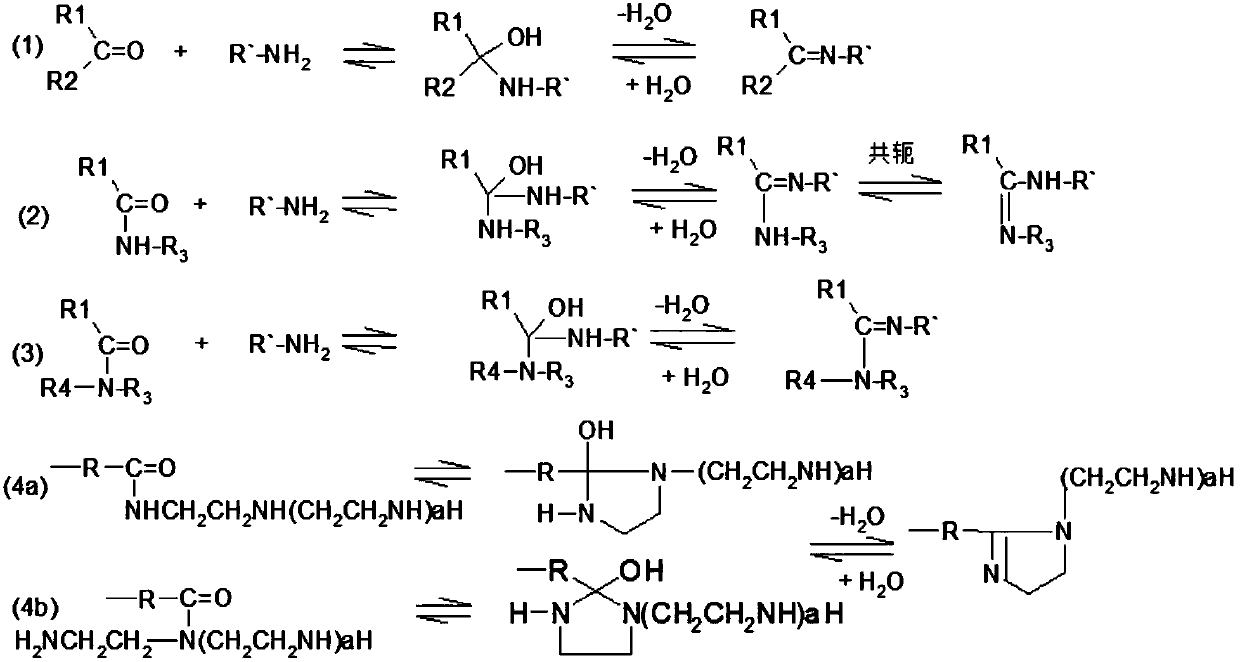

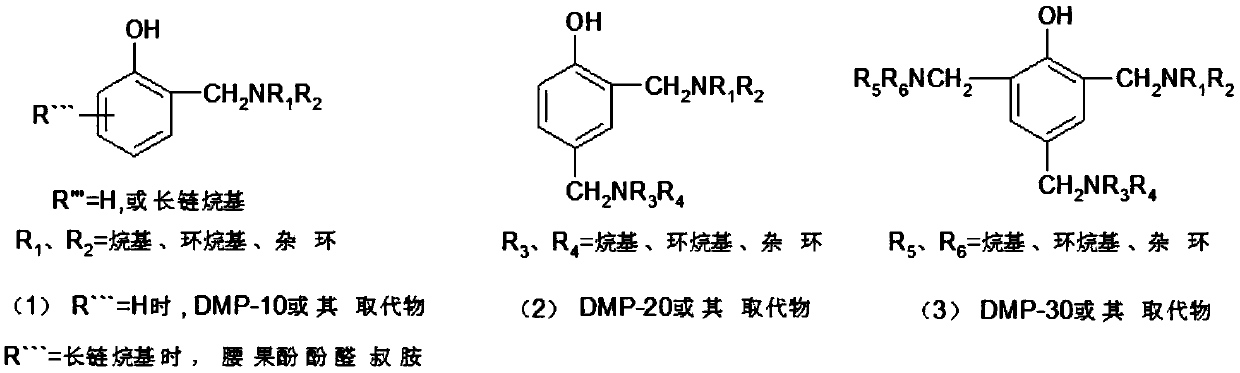

[0074] Embodiment 2: the preparation of phenalkamine

[0075] (1) Phenolic tertiary amine DMP-30 derivative FQSA1: Add 265.4g (1 mole) of 2,4,6-tri-N,N-dimethylaminomethylphenol DMP-30 into a 1000mL three-neck flask, add 129g (1 mole) of di-n-butylamine, heated to 120°C for reflux reaction for 3 hours, then distilled, and the distillate was recovered at low temperature to obtain 48.5g of distillate, which contained 44.1g of dimethylamine by chromatographic analysis . The distillation residue is the phenalk tertiary amine FQSA1 which has partially exchanged dimethylamino with dibutylamino.

[0076] (2) Phenol-formaldehyde long-carbon secondary amine condensate FQSA2: Add 181g (1 mole) of dicyclohexylamine to a 500mL three-necked flask, heat up to 80°C, and gradually add paraformaldehyde solid powder while maintaining a temperature of 80-100°C A total of 30g was stirred and dissolved gradually; after dissolution, 94g of phenol was added, and the temperature was raised to 140-1...

Embodiment 3

[0083] Embodiment 3: the water emulsification dispersibility of solidifying agent

[0084] The water-based amide Schiff base complex curing agent prepared in Example 1 above was mixed with water at a mass ratio of 5:1 and 1:1 to carry out emulsification and dispersion performance experiments, and the results are shown in Table 1 below.

[0085] The water emulsification dispersion performance data of the aqueous amide Schiff base complex solidifying agent prepared in the embodiment 1 of table 1

[0086]

[0087] The aqueous amide Schiff base composite curing agent prepared in Example 1 and the phenalkamine prepared in Example 2 are compounded in a mass ratio of 1:1 to form a composite curing agent, and then the mass ratio of the composite curing agent to water is 5: 1 and 1:1 were mixed and stirred to carry out emulsification and dispersion performance experiments, and the results are shown in Table 2 below.

[0088] Table 2 Water emulsification performance data of water-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com