Photo-thermal free radical polymerization preparation method and application of vinyl polymer

A vinyl polymer, free radical technology, applied in the field of materials, can solve the problems of uneven reaction, affecting performance, unfavorable production environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

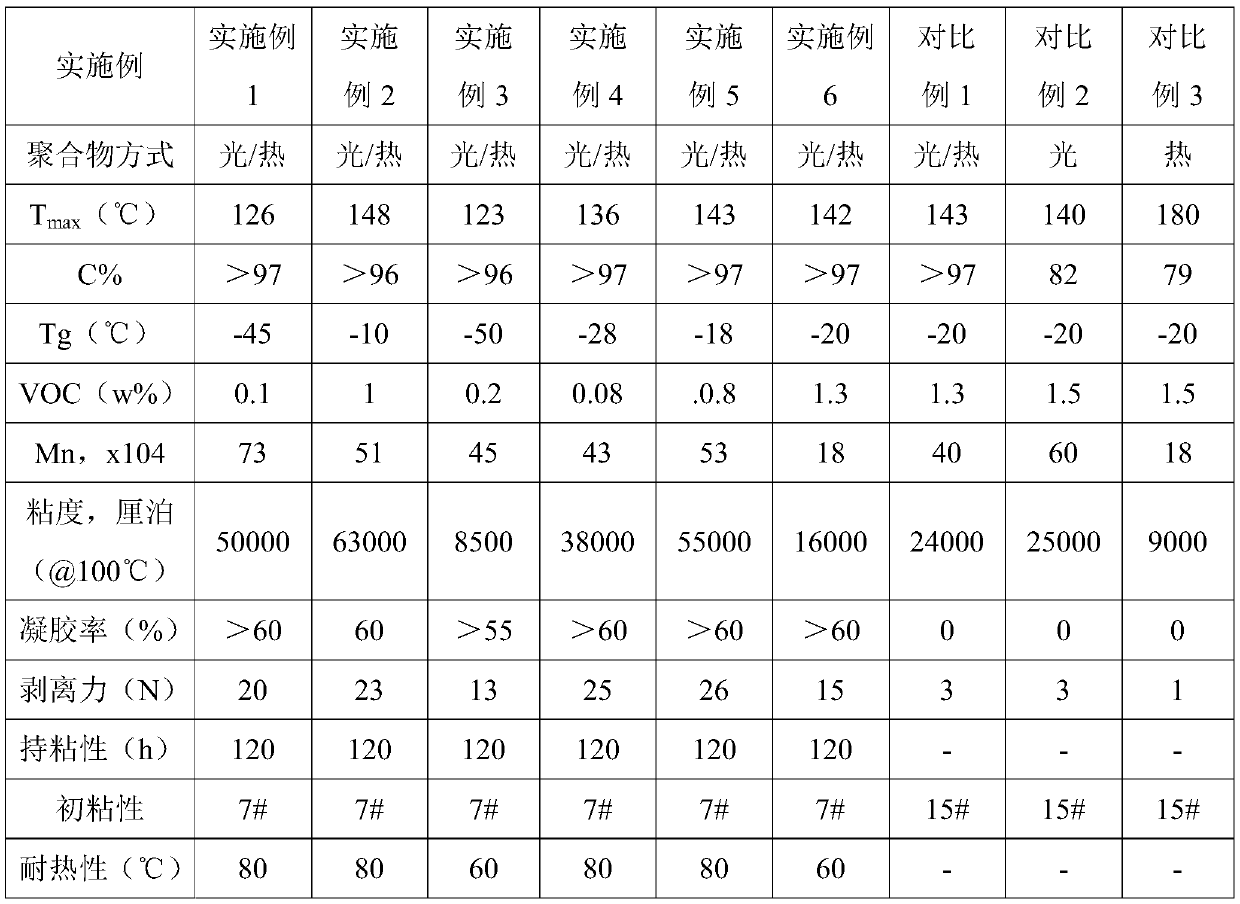

Examples

Embodiment 1

[0071] Solvent-free light / heat-initiated polymerization: soft monomer isononyl acrylate, hard monomer methyl methacrylate and vinyl acetate, functional monomer hydroxypropyl acrylate and acryloyl morpholine, the total amount of the above vinyl monomers is 100g ,Design Tg-40℃, 0.3g photoactive monomer 4-(acryloyloxy)benzophenone, add together with 0.1g photoinitiator TPO, 0.1g thermal initiator AIBN and 0.15g dodecyl mercaptan A 250ml three-neck round bottom flask is equipped with a thermometer, a reflux condenser and a nitrogen inlet, and the nitrogen is connected to a liquid-sealed tube from the top of the reflux condenser. Start stirring, pass 99.999% pure nitrogen for 10 minutes, irradiate the glass bottle with a 15W 365 / 395nm mixed wavelength LED lamp, the temperature will start to rise in about 10 seconds, stop the light when the temperature rises to 65°C, and the temperature in the reactor will continue Rise, there is obvious solvent reflux in the bottle, rise to the hig...

Embodiment 2

[0074] Light / heat initiated polymerization: soft monomer butyl acrylate, hard monomer isobornyl acrylate and vinyl acetate, functional monomer: hydroxypropyl acrylate, N-vinylpyrrolidone, design Tg-13℃, photoinitiator TPO , carry out photopolymerization after stirring and removing oxygen, then turn off the light, add a solution of ethyl acetate dissolved in photoactive monomer 4-(acryloyloxy)fluorenone containing aryl ketone and thermal initiator BPO, and then react for 1h , followed by devolatilization at 120°C and 3kPa, and the rest of the operations were similar to Example 1.

Embodiment 3

[0076] Solvent light / heat initiated polymerization: soft monomer 12 alkyl acrylate, 2(2-ethoxyethoxy) ethyl acrylate, hard monomer methyl methacrylate, cyclohexyl acrylate, functional monomer Hydroxypropyl acrylate, tetrahydrofuryl acrylate, design Tg-54°C, solvent ethyl acetate 10w%, photoinitiator TPO, semi-thermal initiator AIBN, and chain transfer agent mercaptoethanol are mixed to deoxygenate and carry out photopolymerization, and then turn off the light; Subsequently, the solution of ethyl acetate dissolved with the photoactive monomer 4-(2-acryloyloxyethoxy)-benzophenone containing aryl ketone and the other semi-thermal initiator tert-butyl peroxyacetate was exposed to light. Drop in within 15 minutes after stopping, and after another 1 hour of reaction, then add 0.1w% antioxidant 168 of the total amount of polymerization and 0.8w% antioxidant 1010 of the total amount of polymer; then pump into the surface renewal type devolatilization device, and the rest of the operat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com