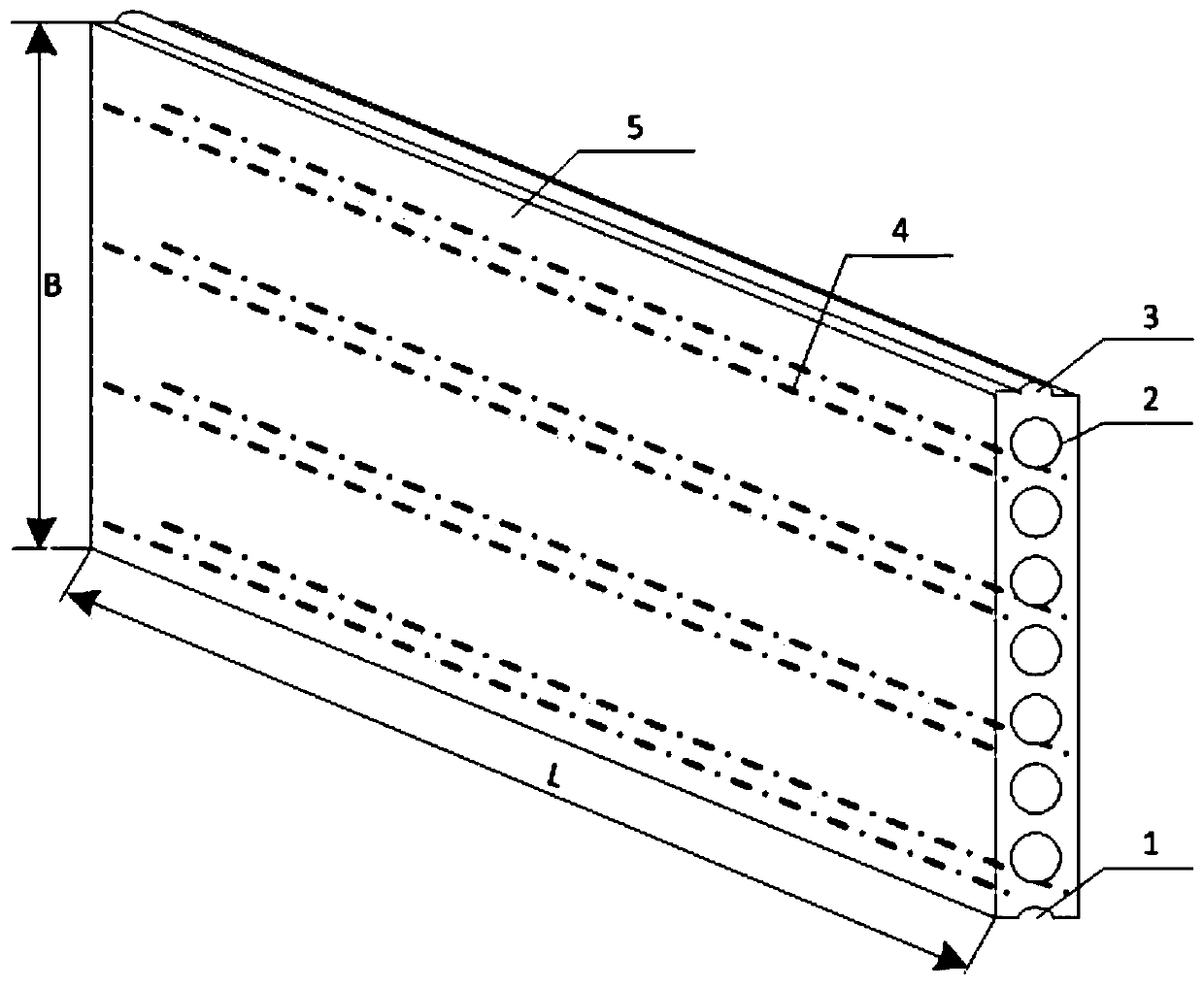

All brick slag recycled aggregate concrete light partition board and making method thereof

A technology of lightweight partition board and recycled aggregate, applied in the field of building materials, can solve the problems of insufficient utilization value, low density and high price, and achieve the effects of reducing adverse effects, high production efficiency and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Prepare materials in parts by weight: 8 parts of ordinary Portland cement, 5 parts of fly ash, 3 parts of mineral powder, 35 parts of recycled brick fine aggregate, 45 parts of recycled brick coarse aggregate, powdery polycarboxylic acid 0.03 parts of water agent, 0.02 parts of tributyl phosphate (defoamer), 0.08 parts of polypropylene fiber, and 5 parts of water.

[0073] Among them: (1) The specification of ordinary Portland cement is P.O 42.5; (2) The fly ash is grade II, and the mineral powder is grade S95; (3) The mass distribution of the particle size r1 of recycled brick coarse aggregate is: 5mm< r1≤10mm is 25%, 10mm<r1≤16mm is 55%, 16mm<r1≤20mm is 20%, crushing index is 23%, impurity content is 3.2%, 1h water absorption rate is 16.3%; (4) recycled brick The particle size r2 of the fine aggregate is: 0mm<r2≤5mm, the impurity content is 2.9%, and the 1h water absorption rate is 21.5%; (5) the diameter of the polypropylene fiber is 2mm, and the length is 20mm; (6) ...

Embodiment 2

[0090] Prepare materials in parts by weight: 8 parts of ordinary Portland cement, 3 parts of fly ash, 3 parts of mineral powder, 33 parts of recycled brick fine aggregate, 47 parts of recycled brick coarse aggregate, powdery polycarboxylic acid 0.03 parts of water, 0.02 parts of polyethylene glycol (defoamer), 0.01 parts of polyvinyl alcohol (thickener), 0.07 parts of alkali-resistant glass fiber, and 4 parts of water.

[0091] Among them: (1) The specification of ordinary Portland cement is P.O 42.5; (2) The fly ash is grade II, and the mineral powder is grade S95; (3) The mass distribution of the particle size r1 of recycled brick coarse aggregate is: 5mm< r1≤10mm is 24%, 10mm<r1≤16mm is 51%, 16mm<r1≤20mm is 25%, crushing index is 21%, impurity content is 3.6%, 1h water absorption rate is 15.1%; (4) recycled brick The particle size r2 of fine aggregate is: 0mm<r2≤5mm, the impurity content is 4.2%, and the water absorption rate in 1h is 22.3%; (5) the diameter of alkali-resis...

Embodiment 3

[0095] Prepare materials in parts by weight: 10 parts of ordinary Portland cement, 3 parts of fly ash, 2 parts of mineral powder, 1 part of silica fume, 37 parts of recycled brick fine aggregate, 44 parts of recycled brick coarse aggregate, powdered 0.04 parts of polycarboxylic acid superplasticizer, 0.01 parts of polyol (defoamer), 0.09 parts of steel fiber, and 5 parts of water.

[0096] Among them: (1) The specification of ordinary Portland cement is P.O 42.5; (2) The fly ash is grade II, the mineral powder is grade S95, the particle size of silica fume is 0.17um, and the bulk density is 280kg / m 3 (3) The mass distribution of the particle size r1 of recycled brick coarse aggregate is: 5mm<r1≤10mm is 30%, 10mm<r1≤16mm is 48%, 16mm<r1≤20mm is 22%, and the crushing index is 26 %, the impurity content is 5.2%, and the 1h water absorption rate is 18.3%; (4) The particle size r2 of the recycled brick fine aggregate is: 0mm<r2≤5mm, the impurity content is 3.2%, and the 1h water ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com