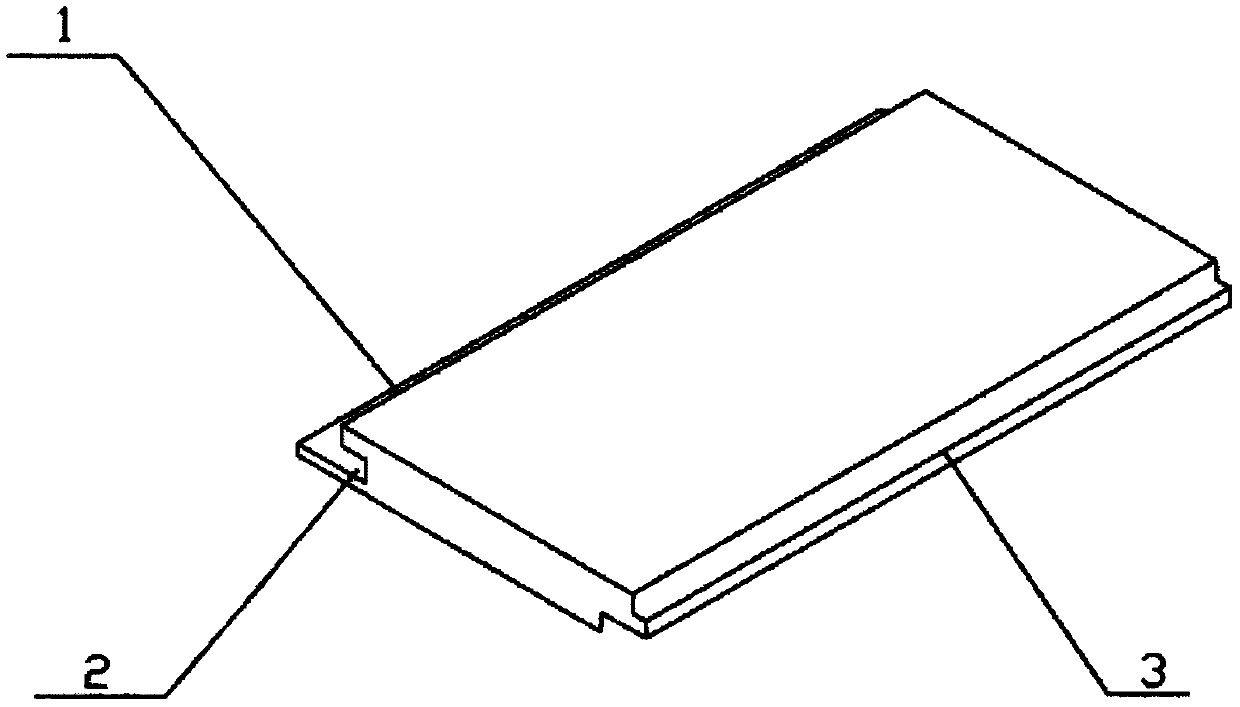

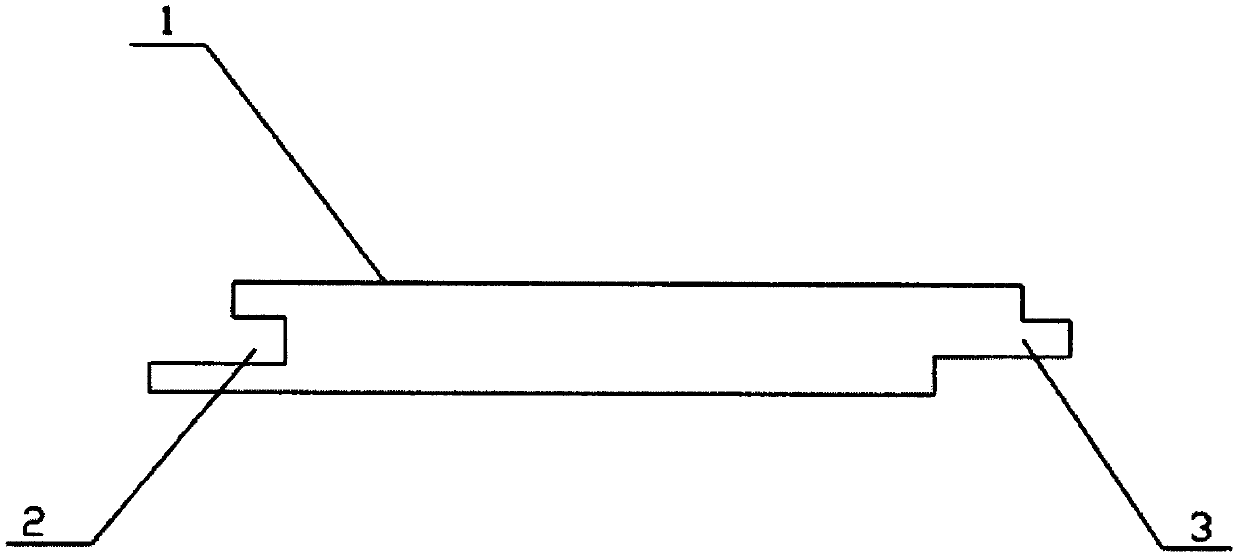

Three-layer solid wood floor with negative ions and capable of removing formaldehyde and production process thereof

A production process, a technology of negative ions, applied in the field of wood flooring, to achieve the effect of improving lung function, improving myocardial nutrition, and reducing the use of wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The raw material formula is:

[0038] Including 33% wood chips, 18% corn stalks, 23% waste rubber, 3% negative ion powder, 1.5% flame retardant, 1.5% waterproofing agent and 12% adhesive.

[0039] Specific steps are as follows:

[0040] Step 1: Cut sawdust, corn stalks and waste rubber separately and grind them into granules, pass through an 80-mesh sieve, put them into a mixer and stir evenly to obtain a mixture;

[0041] Step 2: Add negative ion powder, flame retardant, waterproofing agent and adhesive to the mixture in step 1 in sequence and stir evenly, and shape it by hot pressing to obtain the base material layer;

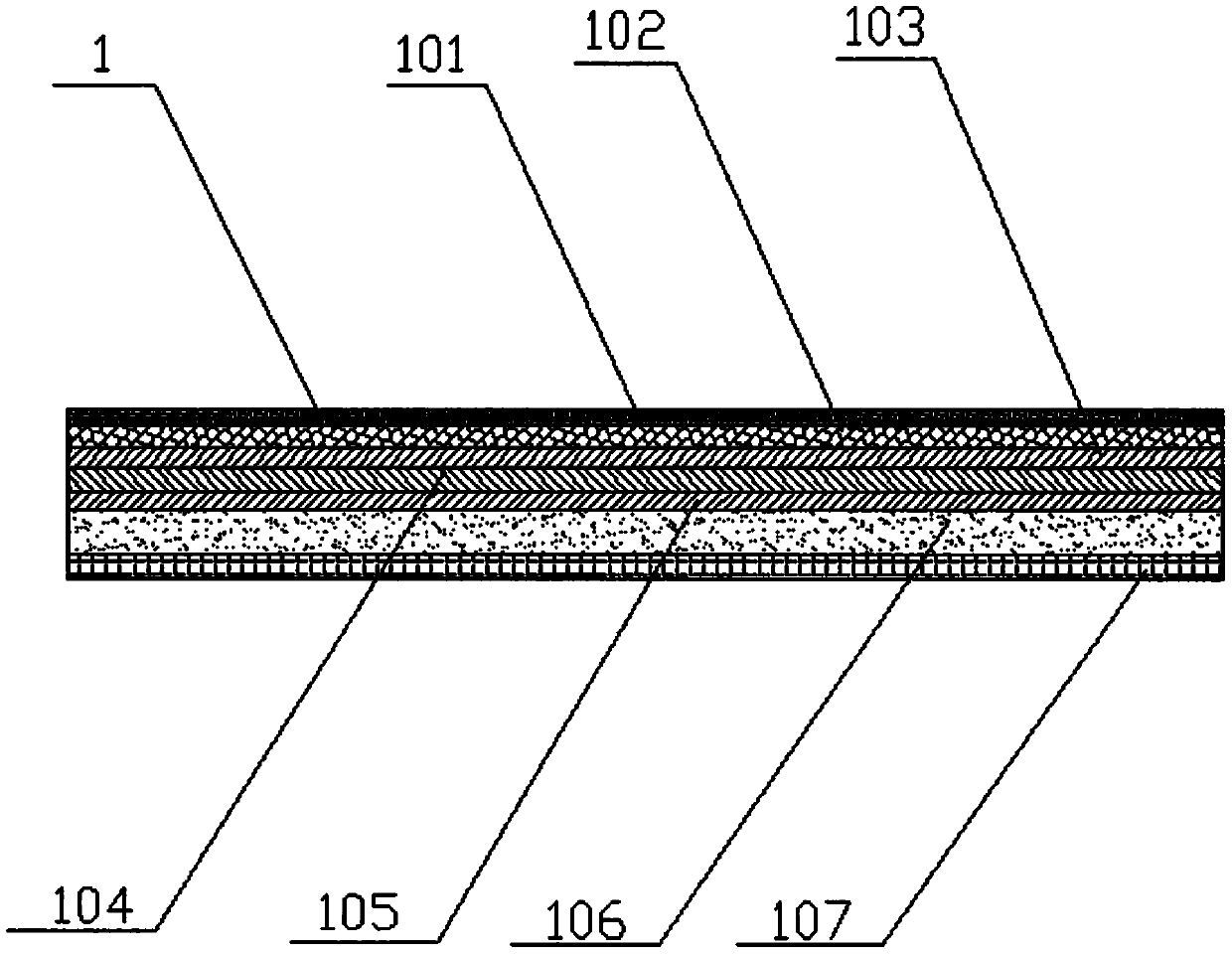

[0042] Step 3: Put the wear-resistant layer, decorative layer, substrate layer, first solid wood layer, second solid wood layer, third solid wood layer and balance layer into a high-temperature press for pressing;

[0043] Step 4: cutting and grooving the pressed wooden floor to obtain a finished wooden floor.

[0044] experimental method:

[0045] S...

Embodiment 2

[0048] The raw material formula is:

[0049] Including 35% wood chips, 20% corn stalks, 25% waste rubber, 5% negative ion powder, 2% flame retardant, 3% waterproofing agent and 10% adhesive.

[0050] Specific steps are as follows:

[0051] Step 1: Cut sawdust, corn stalks and waste rubber separately and grind them into granules, pass through an 80-mesh sieve, put them into a mixer and stir evenly to obtain a mixture;

[0052] Step 2: Add negative ion powder, flame retardant, waterproofing agent and adhesive to the mixture in step 1 in sequence and stir evenly, and shape it by hot pressing to obtain the base material layer;

[0053] Step 3: Put the wear-resistant layer, decorative layer, substrate layer, first solid wood layer, second solid wood layer, third solid wood layer and balance layer into a high-temperature press for pressing;

[0054] Step 4: cutting and grooving the pressed wooden floor to obtain a finished wooden floor.

[0055] experimental method:

[0056] Ste...

Embodiment 3

[0059] The raw material formula is:

[0060] Including 33% of wood chips, 22% of corn stalks, 23% of waste rubber, 7% of negative ion powder, 2.5% of flame retardant, 4.5% of waterproofing agent and 8% of adhesive.

[0061] Specific steps are as follows:

[0062] Step 1: Cut sawdust, corn stalks and waste rubber separately and grind them into granules, pass through an 80-mesh sieve, put them into a mixer and stir evenly to obtain a mixture;

[0063] Step 2: Add negative ion powder, flame retardant, waterproofing agent and adhesive to the mixture in step 1 in sequence and stir evenly, and shape it by hot pressing to obtain the base material layer;

[0064] Step 3: Put the wear-resistant layer, decorative layer, substrate layer, first solid wood layer, second solid wood layer, third solid wood layer and balance layer into a high-temperature press for pressing;

[0065] Step 4: cutting and grooving the pressed wooden floor to obtain a finished wooden floor.

[0066] experiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com