Composite nerve restoration catheter and preparation method thereof

A nerve repair and catheter technology, which is applied in the field of medical biomaterials and medical devices, can solve the problems of poor operability and cumbersome steps, and achieve the effects of improving mechanical strength, simple manufacturing process, and promoting nerve regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Preparation of the inner layer collagen catheter of the composite nerve repair catheter

[0049] Taking the preparation of the inner layer collagen catheter with 6% collagen slurry as an example, the preparation steps of the inner layer catheter are as follows:

[0050] (1) Mix according to the ratio of 0.6g ground and pulverized type I collagen: 10ml (0.6M acetic acid solution), acidify for 200min to obtain a uniform collagen slurry with a concentration of 6% (mass volume ratio);

[0051] (2) Centrifuge the collagen slurry in step (1): the temperature is controlled at 10±2°C, the rotation speed is 4000rpm, and the time is 60min;

[0052] (3) Centrifuge and install to the mould: take a hollow stainless steel cylindrical mold with a diameter of 6 mm and a length of 30 mm, inject the collagen slurry, and insert the mould, with a central axis diameter of 4 mm;

[0053] (4) Freeze-drying: gradient freezing: the mold is placed in the elevator, the descending spee...

Embodiment 2

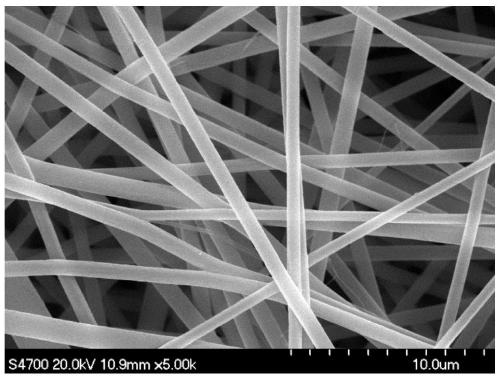

[0058] Example 2: Preparation Method 1 of the Outer Layer of the Composite Nerve Repair Catheter

[0059] (1) Electrospinning process: 0.95g polylactic acid and 0.05g chitosan are dissolved in trifluoroacetic acid, form the spinning solution that uniform chitosan mass content is 5%, polylactic acid: chitosan=9.5 : 0.5 (mass ratio); the collagen catheter prepared by embodiment 1 is placed in an electrostatic field, electrostatic high voltage 20kV, receiving distance 20cm, advancing speed 1.8ml / h, spinning time 90min;

[0060] (2) Vacuum drying at 40°C for 24 hours;

[0061] (3) Ethylene oxide gas sterilization after primary packaging.

Embodiment 3

[0062] Example 3: Preparation Method 2 of the Outer Layer of the Composite Nerve Repair Catheter

[0063] (1) Electrospinning process: 0.9g polylactic acid and 0.1g chitosan are dissolved in trifluoroacetic acid, form the spinning solution of uniform chitosan quality 10%, polylactic acid: chitosan=9:1 (mass ratio); the collagen catheter prepared in Example 1 is placed in an electrostatic field, the electrostatic high voltage is 20kV, the receiving distance is 20cm, the advancing speed is 1.8ml / h, and the spinning time is 90min;

[0064] (2) Vacuum drying at 40°C for 24 hours;

[0065] (3) Ethylene oxide gas sterilization after primary packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com