Surface silver-particle-modified layered double hydroxide gas-sensitive element and preparation method and application thereof

A layered bimetallic and hydroxide technology, applied in nickel oxide/nickel hydroxide, zinc oxide/zinc hydroxide, aluminum oxide/aluminum hydroxide, etc. permission and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Configure the precursor solution required for hydrothermal reaction

[0027] Add sodium lauryl sulfate powder into 50ml deionized water, stir magnetically for 10min to dissolve it completely, and obtain a 0.45mmol / L sodium lauryl sulfate solution. Mix magnesium nitrate and aluminum nitrate powder according to the ratio of 2:1 Add the molar ratio of magnesium to aluminum into the sodium lauryl sulfate solution, keep stirring, weigh 6mmol of urea and dissolve it in 10ml of deionized water, add the obtained urea solution to the above solution drop by drop, and then continue magnetic stirring for 20min .

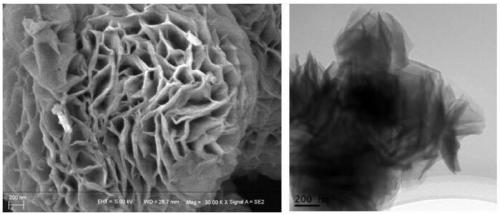

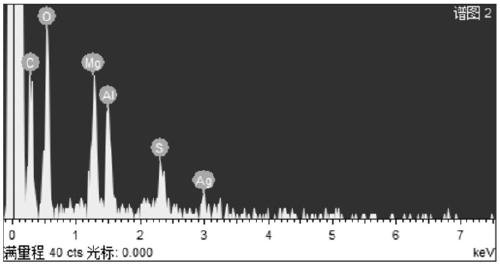

[0028] (2) Preparation of magnesium-aluminum layered double metal hydroxide by hydrothermal method

[0029] The final solution after (1) stirring is transferred to a 100ml high-pressure reactor lined with polytetrafluoroethylene, and after sealing, the reactor is placed in an oven for hydrothermal reaction. The oven operating temperature is 150 ° C, and the heating t...

Embodiment 2

[0040] (1) Configure the precursor solution required for hydrothermal reaction

[0041] Add sodium lauryl sulfate powder into 50ml of deionized water, stir magnetically for 10 minutes, and dissolve it completely to obtain a 0.9mmol / L sodium lauryl sulfate solution. Mix zinc nitrate and aluminum nitrate powder in a ratio of 3:1 Add the molar ratio of zinc to aluminum into the sodium lauryl sulfate solution, keep stirring, weigh 6mmol of urea and dissolve it in 10ml of deionized water, add the obtained urea solution to the above solution drop by drop, and then continue magnetic stirring for 20min .

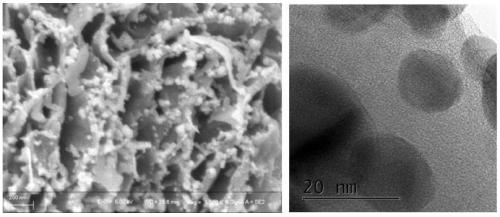

[0042] (2) Preparation of zinc-aluminum layered double metal hydroxides by hydrothermal method

[0043] The final solution after (1) stirring is transferred to a 100ml high-pressure reactor lined with polytetrafluoroethylene, and after sealing, the reactor is placed in an oven for hydrothermal reaction. The oven operating temperature is 150 ° C, and the heating time is 2h.

[004...

Embodiment 3

[0054] (1) Configure the precursor solution required for hydrothermal reaction

[0055] Add sodium lauryl sulfate powder into 50ml of deionized water, stir magnetically for 10min, and dissolve it completely to obtain a 1.8mmol / L sodium lauryl sulfate solution. Mix nickel nitrate and aluminum nitrate powder according to the ratio of 3:1 Add the molar ratio of nickel to aluminum into the sodium lauryl sulfate solution, keep stirring, weigh 6mmol of urea and dissolve it in 10ml of deionized water, add the obtained urea solution to the above solution drop by drop, and then continue magnetic stirring for 20min .

[0056] (2) Preparation of nickel-aluminum layered double hydroxides by hydrothermal method

[0057] The final solution after (1) stirring is transferred to a 100ml high-pressure reactor lined with polytetrafluoroethylene. After sealing, the reactor is placed in an oven for hydrothermal reaction. The operating temperature of the oven is 180 ° C, and the heating time is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com