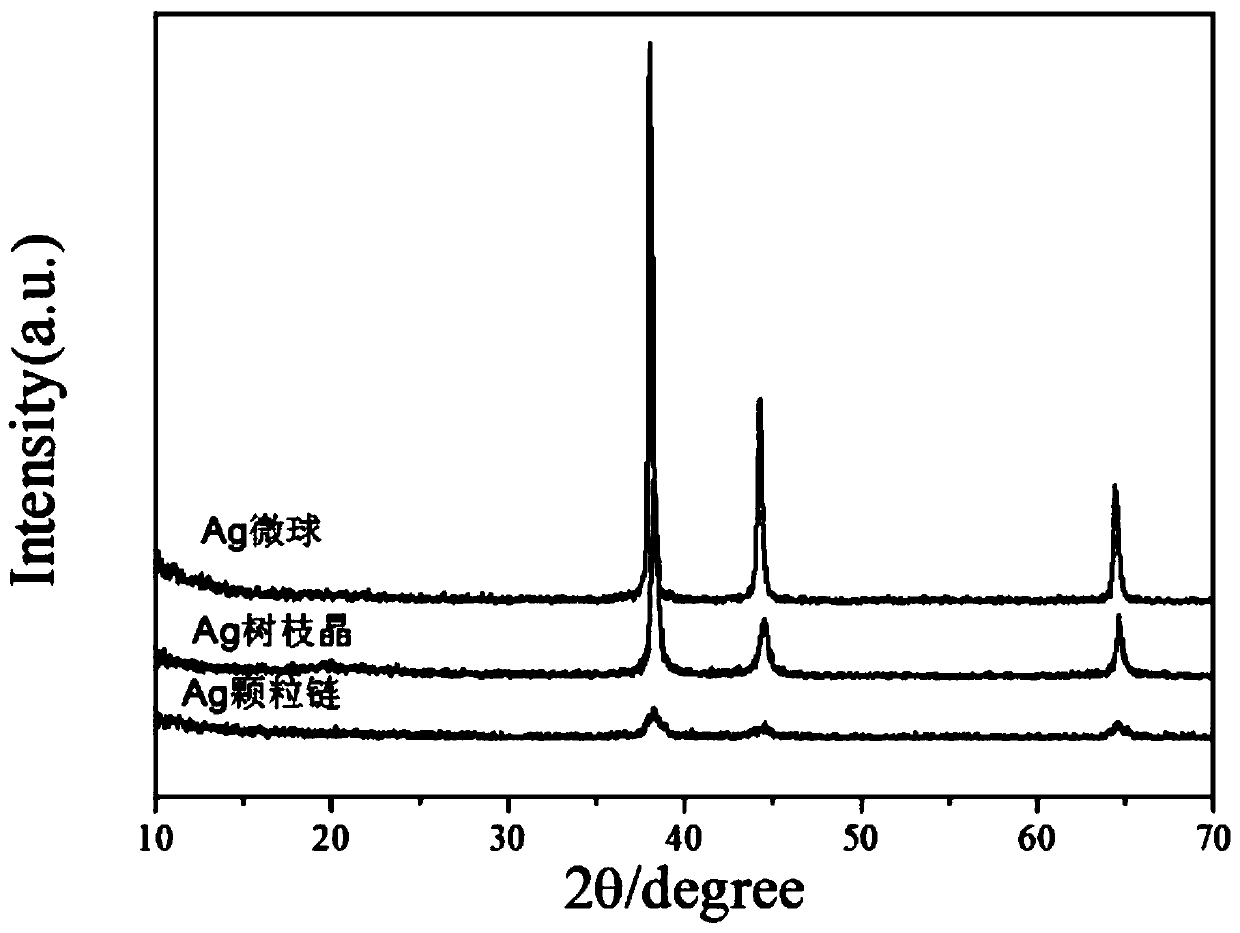

Water-soluble silver micro/nano crystal and controllable preparation method thereof

A silver micro-nano, water-soluble technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of small size of Ag nanocrystals, limit practical application, poor dispersion, etc., and achieve good dispersion and stability , high yield and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of water-soluble silver micro-nano crystals, the steps are as follows:

[0021] 100 mL of AgNO with a concentration of 0.01 mol / L 3 The solution and 0.2 g of VC solids were uniformly mixed, and the water-soluble silver micro-nano crystals were obtained through a reduction reaction for 2 minutes.

Embodiment 2

[0023] A preparation method of water-soluble silver micro-nano crystals, the steps are as follows:

[0024] 1), 100mL of AgNO with a concentration of 0.01mol / L 3 The solution was mixed with 10 mL of 0.2 mol / L blue moon hand sanitizer LYL aqueous solution to obtain the active reaction precursor solution.

[0025] 2), the VC solid of 0.4g is joined in the reaction precursor solution, obtains water-soluble silver micro-nano crystal by reduction reaction 3min.

Embodiment 3

[0027] A preparation method of water-soluble silver micro-nano crystals, the steps are as follows:

[0028] 1), 100mL of AgNO with a concentration of 0.01mol / L 3 The solution was mixed with 10 mL of an aqueous solution of stearic acid microemulsion ALA with a concentration of 0.2 mol / L to obtain an active reaction precursor solution.

[0029] 2), the VC solid of 0.4g is joined in the reaction precursor solution, obtains water-soluble silver micro-nano crystal by reduction reaction 3min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com