Surface treatment process and surface treatment device for basalt fiber profile

A basalt fiber and surface treatment technology, which is applied to the device, spray device, coating and other directions for coating liquid on the surface, can solve the problems of poor spraying effect, poor anti-ultraviolet ability, and inability to flow the paint surface. The effect of UV performance improvement, good product quality, and harm avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

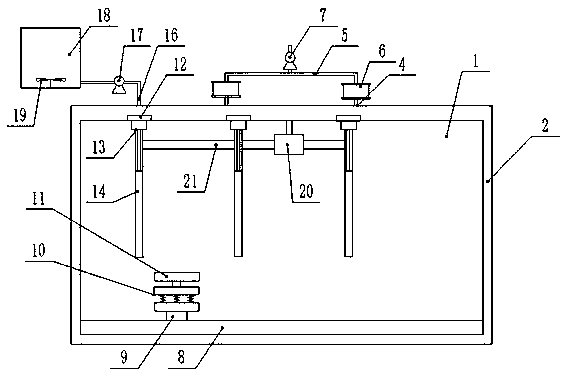

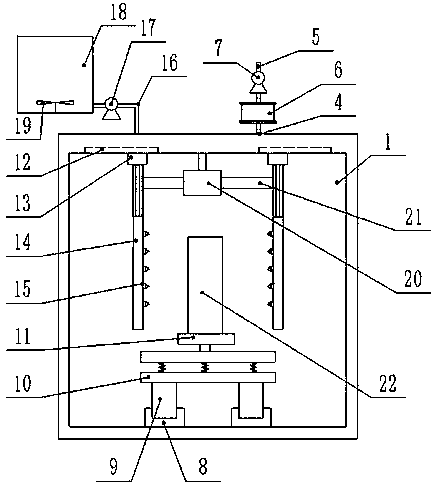

Method used

Image

Examples

Embodiment 1

[0040] A surface treatment process for basalt fiber profiles, comprising the following steps:

[0041] 1) Loading, the basalt fiber profile is loaded for standby, and the surface is polished to obtain a flat surface;

[0042] 2) Preheating, preheating the product surface at 55℃ for 2 minutes after electrostatic dust removal;

[0043] 3) Apply a layer of primer, spray primer treatment on the basalt fiber profiles in the spraying room, and perform leveling treatment for 25 minutes after spraying the primer;

[0044] 4) Apply the second top coat and spray the top coat on the basalt fiber profiles that have been primed in the spraying room. After spraying the top coat, perform leveling treatment for 25 minutes;

[0045] 5) Drying, pre-bake the leveled profiles at a temperature of 75°C for 4 minutes; bake the pre-baked profiles at a temperature of 205°C for 10 minutes;

[0046] 6) Cooling by electrostatic blowing, inspection and storage.

[0047] The primer in the step 3) includ...

Embodiment 2

[0055] A surface treatment process for basalt fiber profiles, comprising the following steps:

[0056] 1) Loading, the basalt fiber profile is loaded for standby, and the surface is polished to obtain a flat surface;

[0057] 2) Preheating, preheating the surface of the product at 50°C for 3 minutes after electrostatic dust removal;

[0058] 3) Apply a layer of primer, spray the primer on the basalt fiber profile in the spraying room, and perform leveling treatment for 20 minutes after spraying the primer;

[0059] 4) Apply three top coats, in the spraying room, spray the top coat on the basalt fiber profiles that have been sprayed with the primer, and perform leveling treatment for 20 minutes after spraying the top coat;

[0060] 5) Drying, pre-bake the leveled profile at 70°C for 5 minutes; bake the pre-baked profile at 200°C for 15 minutes;

[0061] 6) Electrostatic blower cooling, inspection and storage.

[0062] The primer in step 3) includes the following components by ...

Embodiment 3

[0070] A basalt fiber profile surface treatment process, comprising the following steps:

[0071] 1) Loading, the basalt fiber profile is loaded for standby, and the surface is polished to take a flat surface;

[0072] 2) Preheating, preheating the surface of the product at 60°C for 1 minute after electrostatic dust removal;

[0073] 3) Apply a layer of primer, spray the primer on the basalt fiber profile in the spraying room, and perform leveling treatment for 30 minutes after spraying the primer;

[0074] 4) Put on the second top coat, spray the basalt fiber profiles that have been sprayed with the primer in the spraying room, and perform leveling treatment for 30 minutes after spraying the top coat;

[0075] 5) Drying, pre-bake the leveled profile at 80°C for 4 minutes; bake the pre-baked profile at 210°C for 10 minutes;

[0076] 6) Electrostatic blower cooling, inspection and storage.

[0077] The primer in step 3) includes the following components by weight:

[0078] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com