Production process of extra-heavy nodular cast iron manhole cover

A technology of ductile cast iron and production process, which is applied in the production process of super-heavy ductile iron manhole cover, can solve the problems of insufficient bearing capacity, unsuitable manhole cover, and non-corrosion resistance, so as to improve roundness and reduce non-metallic inclusions and slag, eliminate the effect of shrinkage cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

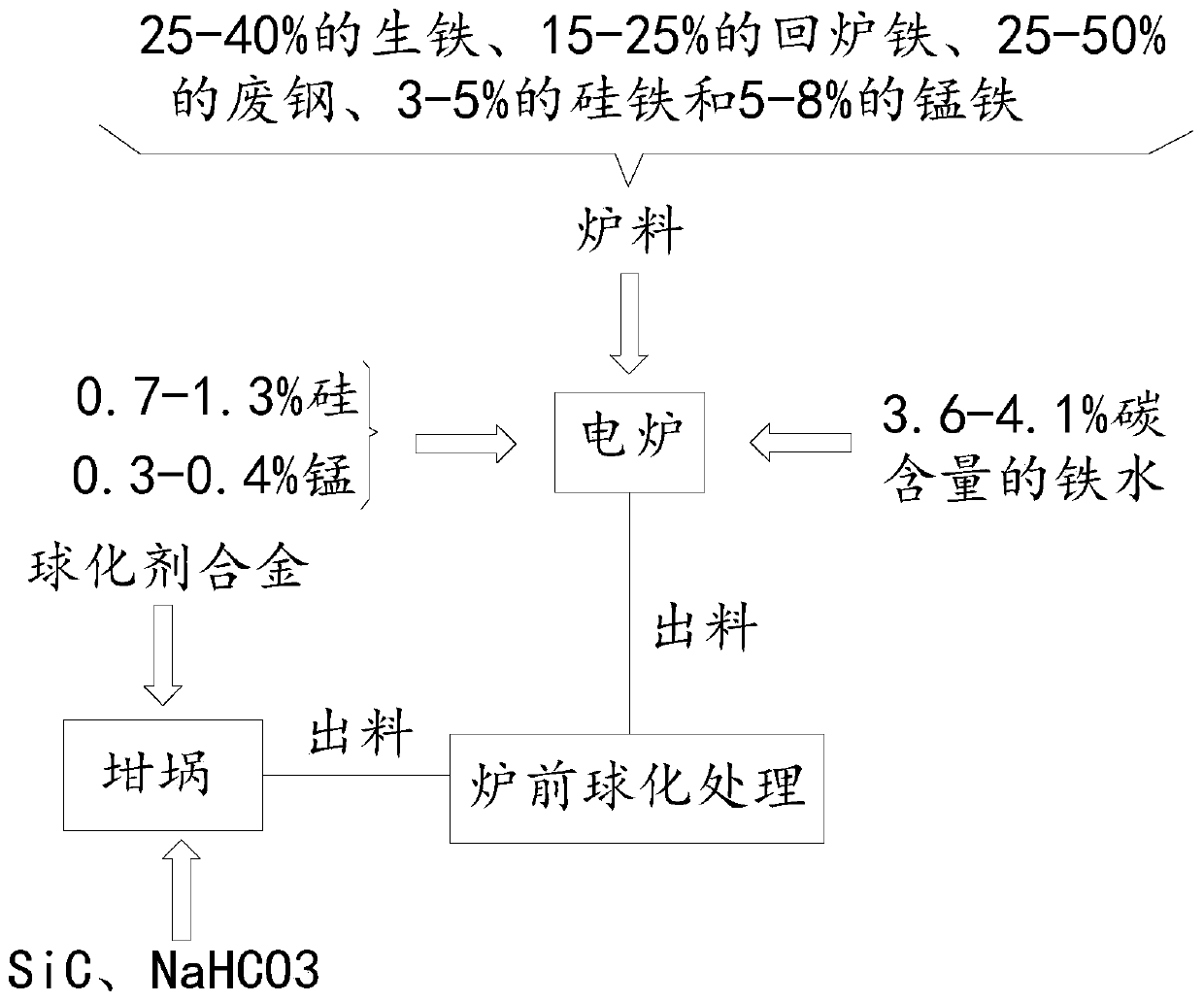

[0024] see figure 1 , in the embodiment of the present invention: provide a kind of super heavy nodular cast iron manhole cover production process, comprise the following steps:

[0025] The first step: choose clay sand and water-based graphite coating with a compactness of 75-85, and use a closed pouring system for pouring. The ratio of sprue: horizontal sprue: inner sprue is 1.25: 2: 1-1.25, A sprue cup is provided on the sprue, a semi-circular runner is used, and a slag collecting bag is set, four ingates are set up vertically in the shape of a trumpet, and a gas riser is left at the last filling part of the molten iron;

[0026] Step 2: Furnace charge ratio: 25% of pig iron, 15% of returned iron, 50% of scrap steel, 3% of ferrosilicon and 7% of ferromanganese are put into the electric furnace for smelting for 20-30min at a temperature of 1750-1800°C;

[0027] Step 3: After the charge is in a molten state, select molten iron with a carbon content of 3.6%, add 0.7% silicon ...

Embodiment 2

[0031] In the embodiment of the present invention: provide a kind of super-heavy nodular cast iron manhole cover production process, comprise the following steps:

[0032] The first step: choose clay sand and water-based graphite coating with a compactness of 75-85, and use a closed pouring system for pouring. The ratio of sprue: horizontal sprue: inner sprue is 1.25: 2: 1-1.25, A sprue cup is provided on the sprue, a semi-circular runner is used, and a slag collecting bag is set, four ingates are set up vertically in the shape of a trumpet, and a gas riser is left at the last filling part of the molten iron;

[0033] Step 2: Furnace charge ratio: 40% of pig iron, 25% of returned iron, 25% of scrap steel, 5% of ferrosilicon and 5% of ferromanganese are put into the electric furnace for smelting for 20-30min at a temperature of 1750-1800°C;

[0034] Step 3: After the charge is in a molten state, select molten iron with 4.1% carbon content, add 1.3% silicon, 0.4% manganese and m...

Embodiment 3

[0038] In the embodiment of the present invention: provide a kind of super-heavy nodular cast iron manhole cover production process, comprise the following steps:

[0039]The first step: choose clay sand and water-based graphite coating with a compactness of 75-85, and use a closed pouring system for pouring. The ratio of sprue: horizontal sprue: inner sprue is 1.25: 2: 1-1.25, A sprue cup is provided on the sprue, a semi-circular runner is used, and a slag collecting bag is set, four ingates are set up vertically in the shape of a trumpet, and a gas riser is left at the last filling part of the molten iron;

[0040] Step 2: Furnace charge ratio: 40% of pig iron, 25% of returned iron, 25% of scrap steel, 5% of ferrosilicon and 5% of ferromanganese are put into the electric furnace for smelting for 20-30min at a temperature of 1750-1800°C;

[0041] Step 3: After the charge is in a molten state, select molten iron with 4.1% carbon content, add 1.3% silicon, 0.4% manganese and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com