Super-absorbent silk fibroin material and production method thereof

A technology of super absorbent material and silk fibroin, applied in the field of super absorbent silk fibroin, can solve the problems of low water absorption rate, high reaction temperature, polluted environment, etc., achieve good biocompatibility, improve swelling ability, and reduce reaction effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of embodiment 1 silk fibroin solution

[0026] Select fresh silkworm cocoons produced in the current year, remove silkworm chrysalis and other sundries, and obtain silkworm cocoon shells. Weigh 80 g silkworm cocoon shells with a precision balance, prepare 4000 mL of sodium bicarbonate / sodium carbonate aqueous solution with a mass fraction of 0.01M and pH=9.5, heat it to boiling with an induction cooker, add the cocoon shells, and adjust the power of the induction cooker to keep the aqueous solution slightly boiling for 30 minutes , take out the cocoons and clean them with deionized water.

[0027] The above test was repeated three times to remove the sericin, and then the cocoon silk was taken out and dried in an oven at 60° C. to obtain pure silk fibroin fibers. Dissolve pure silk fibroin fibers in a lithium bromide solution with a concentration of 9.3mol / L at a bath ratio of 20:150, and dissolve in a constant temperature magnetic stirrer at 60±2°C for...

Embodiment 2

[0028] The preparation of embodiment 2 silk fibroin superabsorbent material

[0029] (1) Adjust the concentration of the pure silk fibroin solution in Example 1 to 30 mg / mL with deionized water to obtain an aqueous silk fibroin solution.

[0030] (2) Add riboflavin and horseradish peroxidase solution to the silk fibroin aqueous solution to obtain a reaction solution. The riboflavin concentration in the reaction solution was 0.3 mM, and the horseradish peroxidase concentration was 20 U / mL.

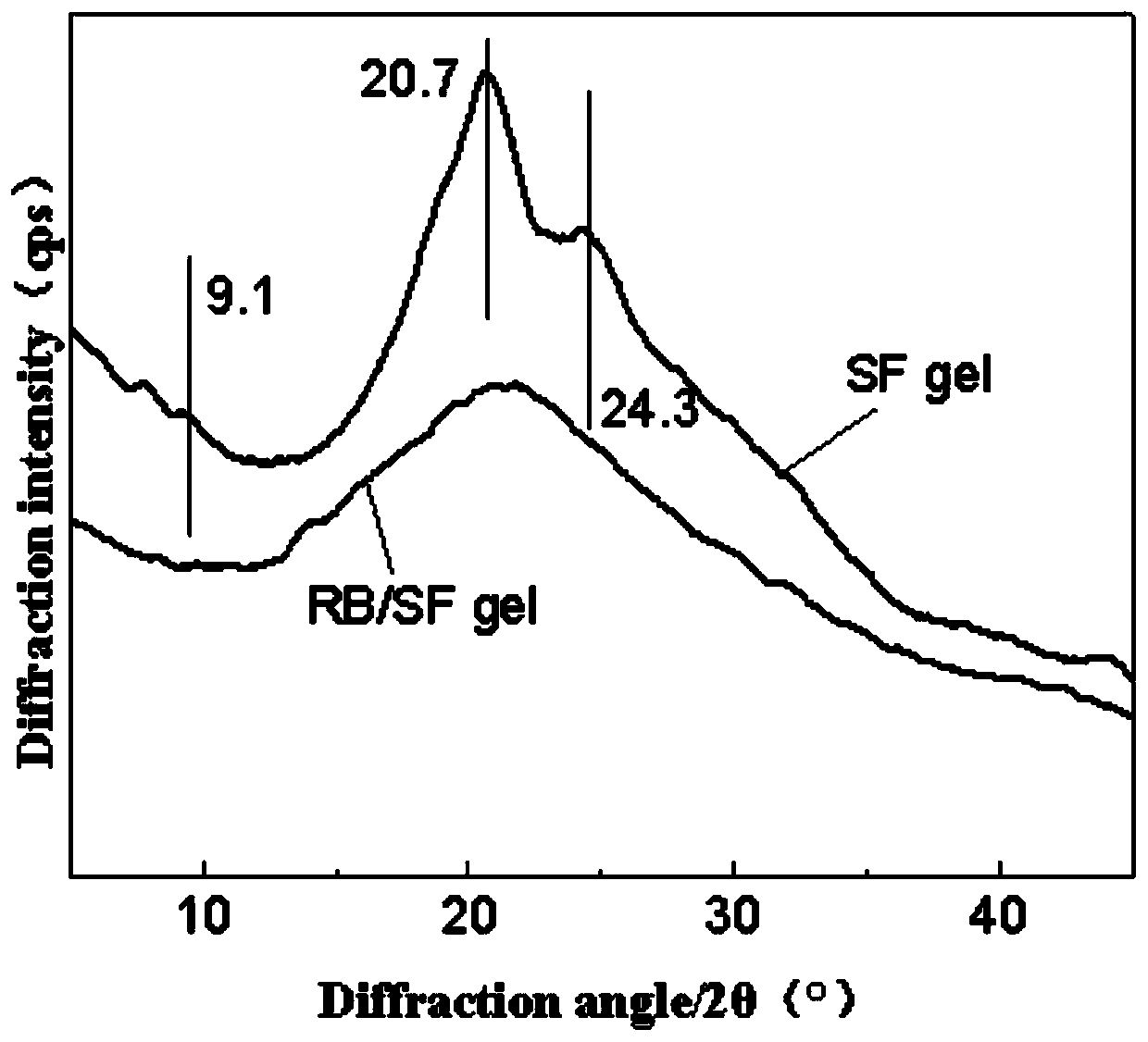

[0031] Most of the cross-linking points in traditional silk fibroin hydrogel are physical cross-linking points, which are easy to slide along the molecular chain during the drying process to produce a large number of crystal structures, which greatly limits its water absorption capacity. Under the irradiation of ultraviolet light, riboflavin generates active oxygen free radicals that can react with tyrosine on the molecular chain of silk fibroin, induce chemical cross-linking of amino grou...

Embodiment 3

[0040] The preparation of embodiment 3 silk fibroin superabsorbent material

[0041] (1) Adjust the concentration of the pure silk fibroin solution in Example 1 to 20 mg / mL with deionized water to obtain an aqueous silk fibroin solution.

[0042] (2) Add riboflavin and horseradish peroxidase solution to the silk fibroin aqueous solution to obtain a reaction solution. The riboflavin concentration in the reaction solution was 0.1 mM, and the horseradish peroxidase concentration was 10 U / mL.

[0043] Most of the cross-linking points in traditional silk fibroin hydrogel are physical cross-linking points, which are easy to slide along the molecular chain during the drying process to produce a large number of crystal structures, which greatly limits its water absorption capacity. Under the irradiation of ultraviolet light, riboflavin generates active oxygen free radicals that can react with tyrosine on the molecular chain of silk fibroin, induce chemical cross-linking of amino grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com