Nanometer ferric oxide/nanometer titanium dioxide composite photocatalyst, and preparation method thereof

A technology of nano-ferric oxide and nano-titanium dioxide, which is applied in the field of preparation of nano-ferric oxide/titanium dioxide composite photocatalysts, can solve problems such as easy recombination, failure to meet expected requirements, and reduced photocatalytic performance. Effect of electron-hole recombination rate, high activity, and visible light catalytic activity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of nano ferric oxide / nano titanium dioxide composite photocatalyst, its step is:

[0017] (1) Dissolve 0.2g-1.80g of ferric nitrate nonahydrate in distilled water, then add 0.10g-0.80g of citric acid and sodium chloride into the solution of ferric nitrate nonahydrate, and stir to obtain a uniform solution;

[0018] (2) Add titanium dioxide powder to prepare a suspension, transfer it to a tube furnace for combustion, and after the reaction is completed, the reaction kettle is naturally cooled to room temperature and washed repeatedly;

[0019] (3) After washing, place the sample in a vacuum drying oven at a temperature of 60°C for 2 hours to dry the sample.

[0020] In the preparation method of the nanometer ferric oxide / nanotitanium dioxide composite photocatalyst mentioned above, the stirring adopts magnetic stirring for 30 minutes.

[0021] The above-mentioned preparation method of nano-ferric oxide / nano-titanium dioxide composite photocatalyst...

Embodiment 1

[0029] Embodiment 1: Preparation of nano-ferric oxide / nano-titanium dioxide photocatalyst:

[0030] (1) According to 0.1% Fe 3+ :1Ti 4+ The molar ratio of Fe(NO 3 ) 3 .9H 2 O and TiO 2 , then take a certain amount of citric acid and sodium chloride according to the chemical reaction equation;

[0031] (2) Mix the above reactants evenly in a mortar and grind them;

[0032] (3) Transfer to a beaker and add a small amount of distilled water, and ultrasonically disperse until uniform;

[0033] (4) Transfer the above sample to a quartz crucible and burn it in a tube furnace at 700°C for 2 hours;

[0034] (5) After the reaction is completed, the reaction kettle is naturally cooled to room temperature, and then the sample is taken out, and washed with water and alcohol repeatedly;

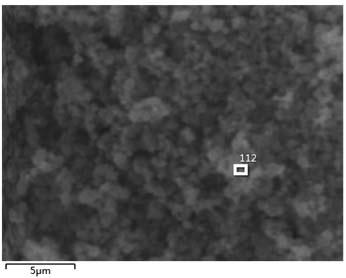

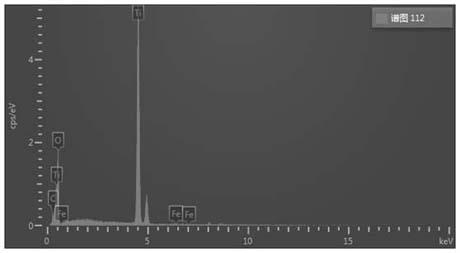

[0035] Table 1. Energy Spectrum Data Sheet:

[0036] element wt% wt% Sigma atomic percentage C 3.52 0.53 6.57 O 51.81 0.87 72.55 Ti 44.56 0.81 20.84 Fe...

Embodiment 2

[0038] Embodiment 2: The preparation method of nano-ferric oxide / nano-titanium dioxide photocatalyst:

[0039] (1) According to 0.1% Fe 3+ :1Ti 4+ The molar ratio of Fe(NO 3 ) 3 .9H 2 O and P25TiO 2 , then take a certain amount of citric acid and sodium chloride according to the chemical reaction equation;

[0040] (2) Mix the above reactants evenly in a mortar and grind them;

[0041] (3) Transfer to a beaker and add a small amount of distilled water, and ultrasonically disperse until uniform;

[0042] (4) Transfer the above sample to a quartz crucible and burn it in a tube furnace at 500°C for 2 hours;

[0043] (5) After the reaction is completed, the reactor is naturally cooled to room temperature, and then the samples are taken out, and washed with water and alcohol repeatedly.

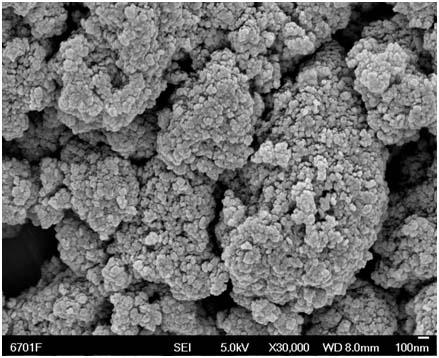

[0044] The EDS and SEM characterizations of the samples showed that the nanometer ferric oxide / titanium dioxide was successfully matched, and the prepared photocatalyst was used to degrad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com