A hydraulic self-adaptive dynamic water and fertilizer mixed rectifier regulator and method

A water-fertilizer mixing and self-adapting technology, which is applied in fluid mixers, pressurized spreading methods of liquid fertilizers, chemical instruments and methods, etc. It can reduce the variation of water flow and pressure, improve the management level of agricultural irrigation, and keep the direction of flow rate consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

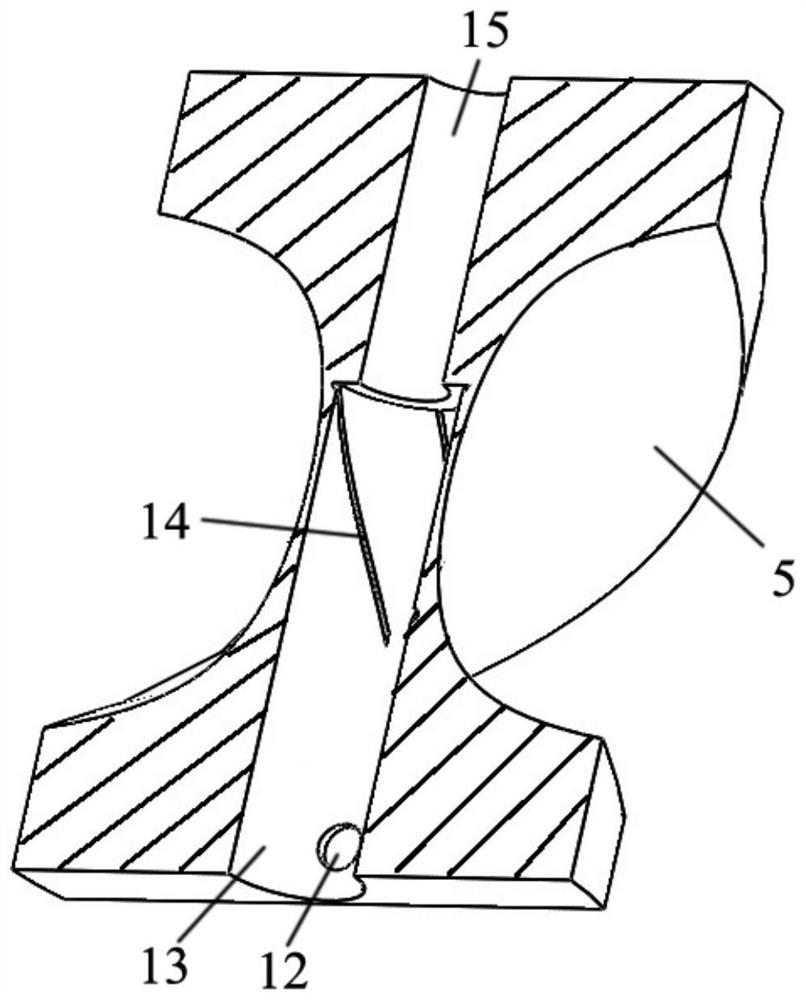

[0051] A hydraulic self-adaptive dynamic water and fertilizer mixing rectifier regulator of the present invention includes mixing blades, blade mounting shaft 22, adjustment mechanism and sleeve 7; the adoption of dynamic mixing blades solves the problem of flow rate and The dynamic change of pressure can not be automatically adapted and the problem of feedback adjustment; using dynamic mixing blades, in the process of water and fertilizer mixing, the water and fertilizer mixture is divided into two parts of fluid, and the two parts of fluid undergo compression and expansion processes, which increases the time of water and fertilizer mixing and improves the efficiency. The degree of mixing of water and fertilizer.

[0052] Specifically, such as figure 1 and Figure 17 As shown, the two ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com