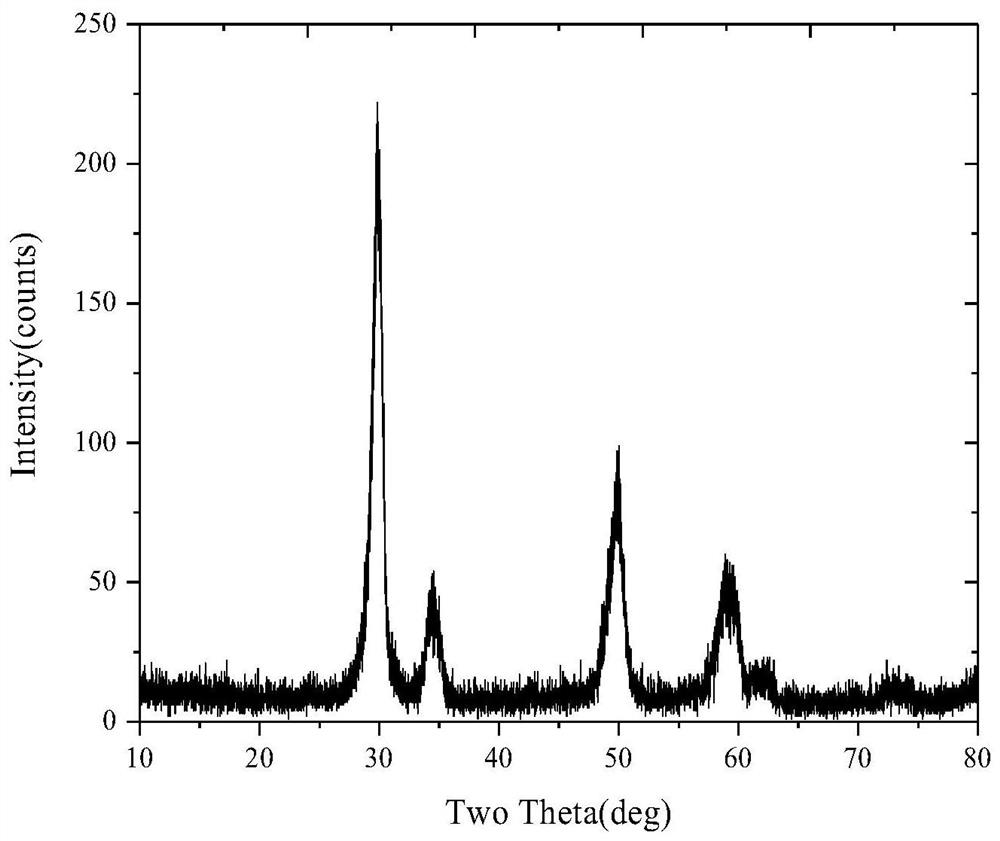

A kind of cerium zirconium composite oxide and preparation method thereof

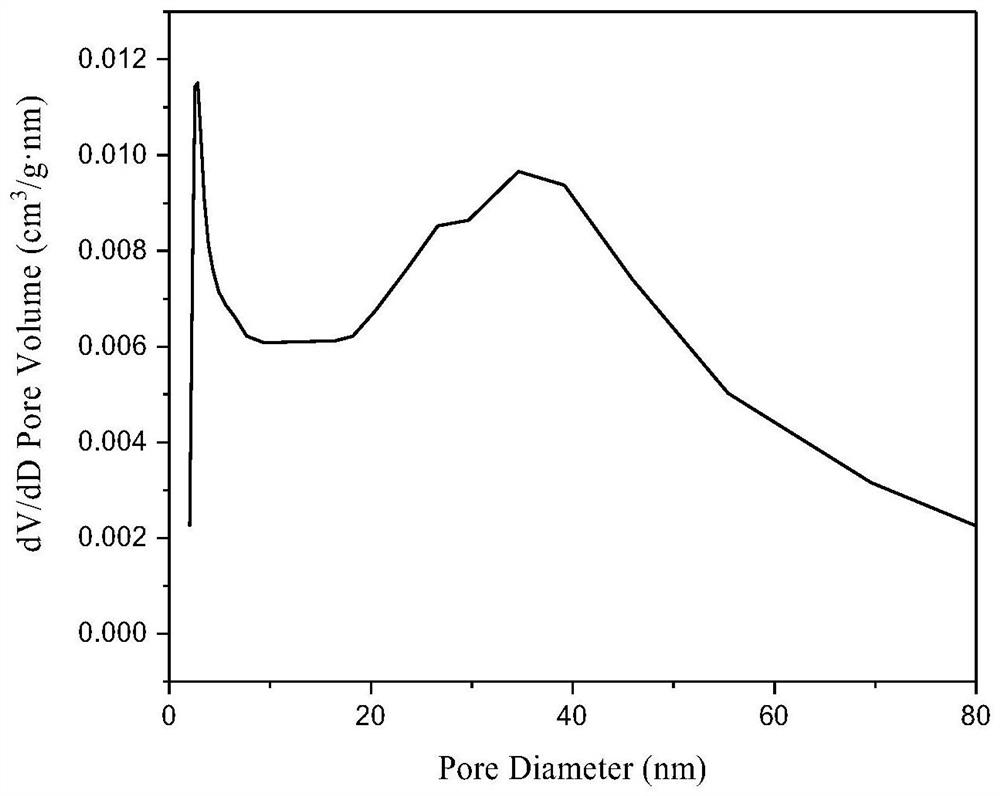

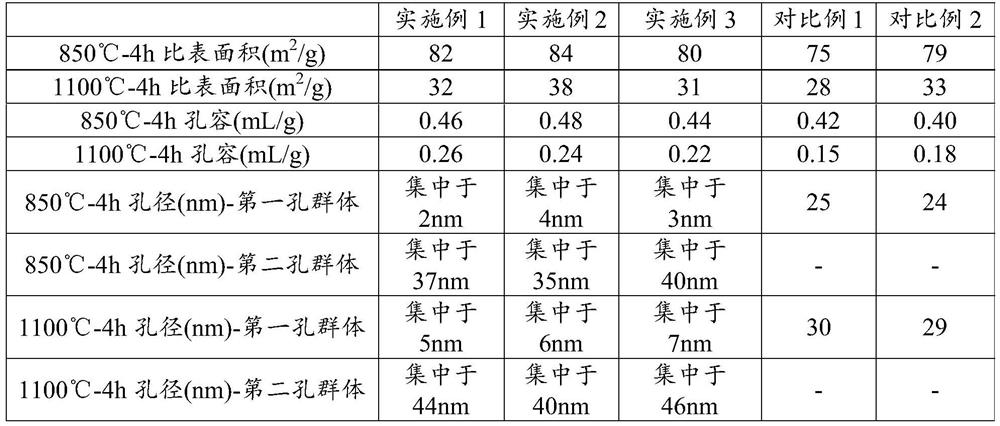

A composite oxide and cerium-zirconium technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problems of inapplicability to industrial production and high cost, and achieve good results Effects of low-temperature catalytic activity, large pore volume, and high oxygen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention provides a preparation method of cerium-zirconium composite oxide, comprising the following steps:

[0047] S1, preparation of seed crystals: zirconium oxychloride is dissolved in pure water to prepare a solution, and the pH value is adjusted to 1.2-2.0. The zirconium oxychloride solution was added to the autoclave, heated at 150°C to 180°C for 24 hours to obtain a white precipitate, which was filtered and washed for later use;

[0048] S2, liquid preparation: dissolve the cerium source, zirconium source and other rare earth elements except cerium in pure water to obtain a mixed solution;

[0049] S3, precipitation: adding the seed crystal obtained in step S1 into the aqueous ammonia solution, and introducing the mixed solution obtained in step S2 into it, adjusting the pH to 10-11, to obtain a mixed precipitate, and washing until there is no chloride ion;

[0050] S4, hydrothermal: the mixed precipitate obtained in step S3 is introduced into the autoclav...

Embodiment 1

[0053] Embodiment 1 provides a composition comprising CeO 2 40%, ZrO 2 50%, La 2 O 3 5%, Pr 6 O 11 5% cerium zirconium composite oxide, prepared by the following method:

[0054] Dissolve 139 g of zirconium oxychloride in pure water to make a solution, adjust the pH to 2, place it in an autoclave, heat and react at 180 °C for 24 h to obtain a zirconium seed crystal precipitate, which is filtered and washed and added to the aqueous ammonia solution;

[0055] 559g of zirconium oxychloride, 622g of ceric ammonium nitrate, 65g of lanthanum nitrate and 58g of praseodymium nitrate were added to 1500mL of ultrapure water, and stirred for 0.5h to obtain a clear solution, which was introduced into the above-mentioned ammonia solution containing zirconium seed crystal precipitate , adjust the pH to 10 to obtain a mixed precipitate of cerium hydroxide-zirconium hydroxide-lanthanum hydroxide-praseodymium hydroxide;

[0056] The mixed precipitate was filtered and washed for at le...

Embodiment 2

[0062] Embodiment 2 provides a composition comprising CeO 2 20%, ZrO 2 73%, La 2 O 3 2%, Nd 2 O 3 5% cerium zirconium composite oxide, prepared by the following method:

[0063] Dissolve 182g of zirconium oxychloride in pure water to make a solution, adjust the pH to 2, place it in an autoclave, heat and react at 170°C for 24h to obtain a zirconium seed crystal precipitate, which is filtered and washed and added to the aqueous ammonia solution;

[0064] Take 838g of zirconium oxychloride, 311g of ceric ammonium nitrate, 26g of lanthanum nitrate and 65g of neodymium nitrate, add them to 1500mL of ultrapure water, and stir for 0.5h to obtain a clear solution, which is introduced into the above-mentioned ammonia solution containing the zirconium seed crystal precipitate , adjust the pH to 10 to obtain a mixed precipitate of cerium hydroxide-zirconium hydroxide-lanthanum hydroxide-neodymium hydroxide;

[0065] The above precipitate was filtered and washed for at least 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com