Functionalized nanofiber three-dimensional net-shaped flexible sensing film and preparation method and application thereof

A sensing film, three-dimensional mesh technology, applied in the organic composite and inorganic fields, can solve the problems of air flow and filtration efficiency can not have both, can not meet the high-efficiency filtration PM, the filter is bulky, etc., and achieves a novel and enhanced network structure. Interconnectivity, simple crafting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

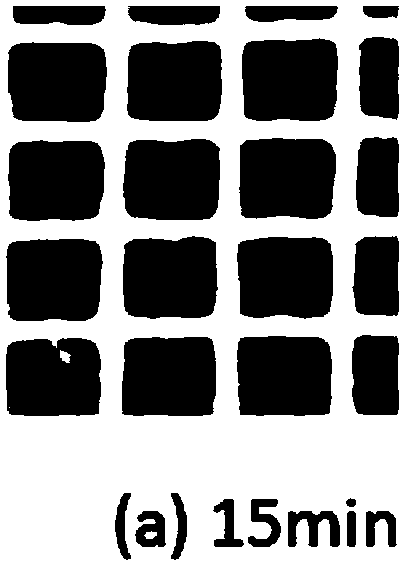

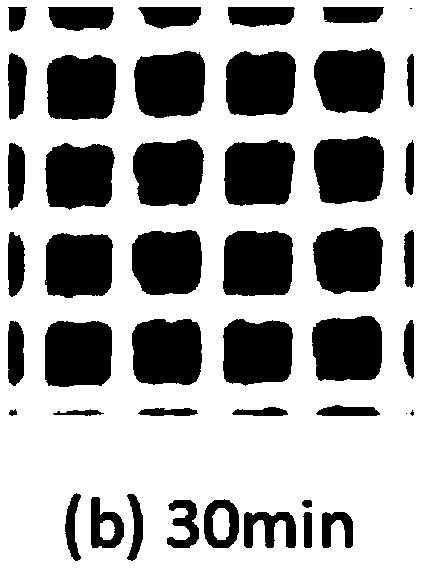

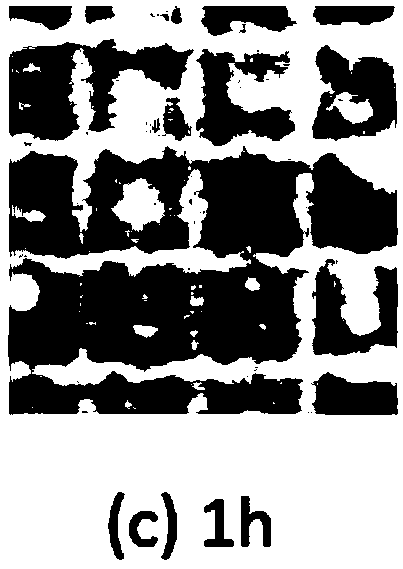

[0038] 1a: First, dissolve 1 g of polyacrylonitrile (PAN) in a mixture of 7 mL of N,N-dimethylformamide (DMF) and 3 mL of acetone, wherein the concentration of polyacrylonitrile is 10% (mass fraction), and magnetically stir After 6-8 hours, it will become viscous and transparent; fill the syringe and place the syringe on the pusher to fix it. The receivers are screens of different thicknesses, and the base is aluminum foil. Connect the positive and negative poles of the high voltage to the syringe needle and the aluminum foil respectively to form an electric field. The resulting electric field can be made into nanofibers by passing the polymer solution through the syringe. Adjust the distance between the needle tip of the syringe and the collection device to 15cm, set the voltage between the emission device and the collection device to 20kV, adjust the output speed of the syringe pump to 0.5mL / h, and electrospin for 15min, 30min, 1h to obtain nanofiber films Wrapped mesh scr...

Embodiment 2

[0054] 2a: Refer to step 1a in Example 1 to prepare a three-dimensional network skeleton of polyacrylonitrile nanofibers.

[0055] 2b: Refer to step 1b in Example 1, wherein dimethyl yellow is replaced by chromotropic acid, and other steps are the same to prepare a mixed function solution.

[0056] 2c: See 1c in Example 1.

[0057] 2d: Refer to 1d in Example 1 to obtain a polyacrylonitrile nanofiber film.

[0058] The polyacrylonitrile nanofibers prepared in the above examples are arranged randomly on the mesh screen window, and the functional solutions of hydroxylamine sulfate and chromotropic acid are evenly wrapped on the surface of the polyacrylonitrile nanofibers with the three-dimensional network skeleton.

[0059] The polyacrylonitrile nanofiber film prepared in Example 2 was assembled on a gas sensing device for formaldehyde gas detection.

[0060] Performance testing: the prepared polyacrylonitrile nanofiber film was cut into 4cm×4cm and placed in a sealed cover (sa...

Embodiment 3

[0065] 3a: Prepare a 15wt% polyvinylpyrrolidone (PVP) ethanol solution, refer to the method of 1a in Example 1, and electrospin for 1 hour to prepare a polyvinylpyrrolidone three-dimensional network skeleton.

[0066] 3b: Dissolve 0.1 g of zinc tetraphenylporphyrin in 50 mL of chloroform solution, stir and dissolve to prepare a functional solution.

[0067] 3c: Cut the prepared three-dimensional network skeleton into a size of 5 cm × 5 cm, then soak it in the mixed functional solution prepared in 3b for 15 seconds, take it out and immerse it again, and repeat this three times.

[0068] 3d: The functionalized film is taken out and dried in a vacuum oven to obtain a polyvinylpyrrolidone nanofiber film.

[0069] The polyvinylpyrrolidone nanofibers prepared in the above example are arranged randomly on the mesh screen window, and the zinc tetraphenylporphyrin functional solution is evenly wrapped on the surface of the polyvinylpyrrolidone nanofibers with the three-dimensional netw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com