Rotor, motor and electric vehicle

A rotor and rotor shaft technology, applied in the field of electric vehicles, can solve the problems of loss of motor kinetic energy, low rotor iron consumption, limited heat generation, etc., and achieve the effect of reducing kinetic energy loss and effective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose, technical solution and advantages of the application clearer, the application will be further described in detail below in conjunction with the accompanying drawings.

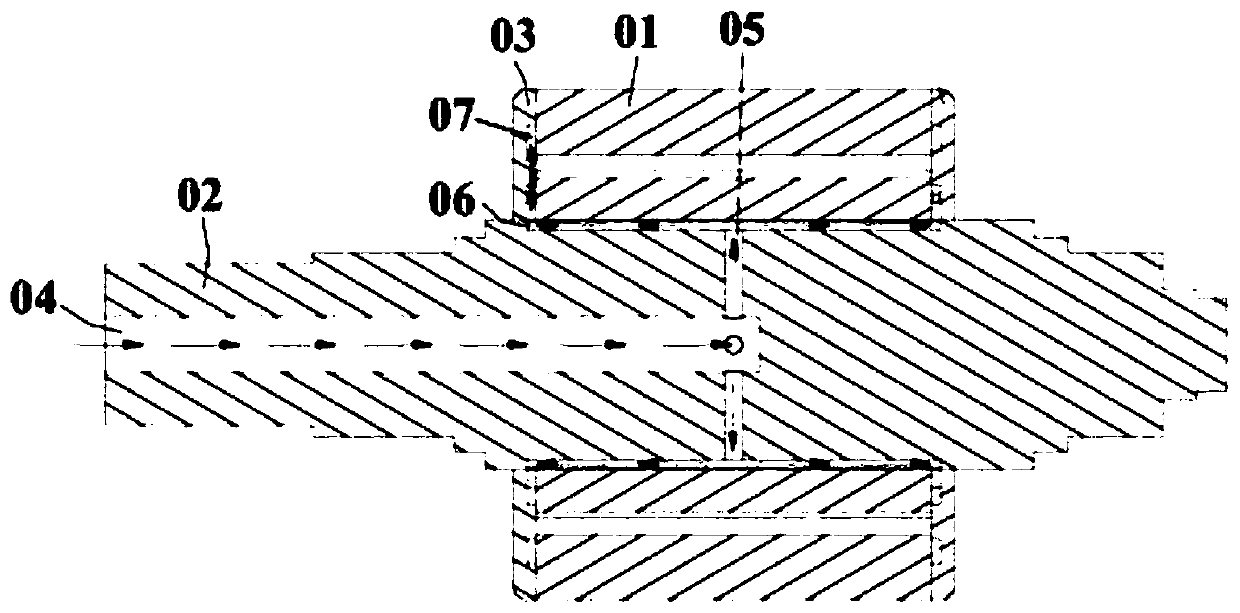

[0042] In view of the poor heat dissipation effect caused by the water-cooled heat dissipation technology and the high requirements for structural precision, some motors are gradually adopting oil-cooled heat dissipation instead of water-cooled heat dissipation. like figure 1 The shown motor adopts oil cooling heat dissipation technology, its structure includes a rotor core 01 and a rotor shaft 02 fixedly assembled in the rotor core 01, in addition, the two ends of the rotor core 01 are respectively provided with fixing plates 03 , The fixing plate 03 is provided with a through hole through which the rotor shaft can pass. When arranging the cooling passage, one end surface of the rotor shaft 02 is provided with a blind hole 04 arranged in the axial direction, and at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com