Fermenting medium and method for producing spores by liquid submerged fermentation of Purpureocillium lilacinum

A liquid submerged fermentation and fermentation medium technology, applied in the field of bioengineering, to achieve the effects of shortening the fermentation cycle, promoting production and maturation, and promoting sporulation and spore maturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: a kind of fermented medium of Paecilomyces lilacinus liquid fermentation produces spore, contains the material of following proportioning: sucrose 45g / L, soluble starch 40g / L, soybean powder 20g / L, potassium dihydrogen phosphate 4g / L L, anhydrous calcium chloride 0.1g / L, magnesium sulfate heptahydrate 0.3g / L, cobalt chloride hexahydrate 0.01g / L, ferric sulfate heptahydrate 0.05g / L, manganese sulfate monohydrate 0.005g / L, seven Zinc sulfate hydrate 0.014g / L.

Embodiment 2

[0026] Embodiment 2: a kind of fermented medium of Paecilomyces lilacinus liquid fermentation produces spore, contains the following material of proportioning: glucose 80g / L, soluble starch 23g / L, cottonseed powder 35g / L, potassium dihydrogen phosphate 2g / L L, calcium chloride anhydrous 0.4g / L, magnesium sulfate heptahydrate 0.1-g / L, cobalt chloride hexahydrate 0.037g / L, iron sulfate heptahydrate 0.01g / L, manganese sulfate monohydrate 0.016g / L, Zinc sulfate heptahydrate 0.005g / L.

Embodiment 3

[0027] Embodiment 3: a kind of fermented medium of Paecilomyces lilacinus liquid fermentation produces spore, contains the material of following proportioning: sucrose 45g / L, soluble starch 23g / L, soybean powder 20g / L, potassium dihydrogen phosphate 4g / L L, anhydrous calcium chloride 0.3g / L, magnesium sulfate heptahydrate 0.3g / L, cobalt chloride hexahydrate 0.037g / L, iron sulfate heptahydrate 0.05g / L, manganese sulfate monohydrate 0.016g / L, seven Zinc sulfate hydrate 0.014g / L.

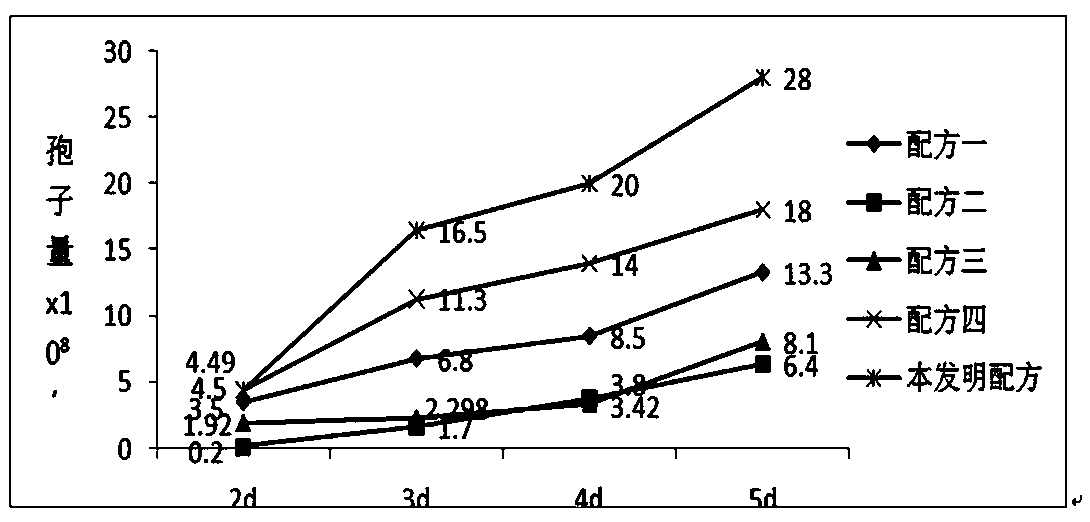

[0028] Embodiment: 4: the impact comparison of different fermentation medium formulas on sporulation effect

[0029] (1) Fermentation medium formula:

[0030] Formula 1: glucose 80g / L, soybean powder 35g / L, potassium dihydrogen phosphate 10g, zinc sulfate 0.1g;

[0031] Formula 2: glucose 80g / L, tryptone 16g / L, potassium dihydrogen phosphate 10g, zinc sulfate 0.1g;

[0032] Formula 3: glucose 80g / L cottonseed cake powder 50g / L, potassium dihydrogen phosphate 10g, zinc sulfate 0.1g;

[0033] Formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com