Sludge conditioner and sludge drying treatment method

A sludge conditioning and sludge drying technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. Pollution and other problems, to achieve the effect of stable sludge structure, good treatment effect and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

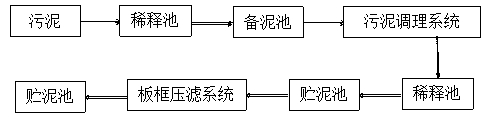

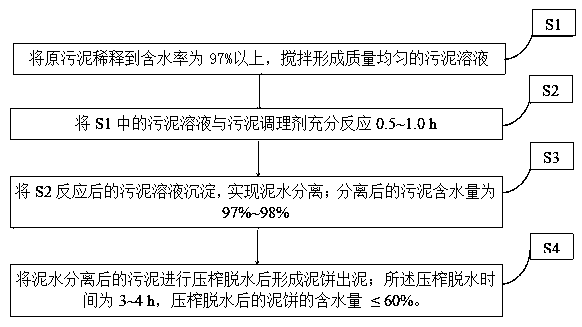

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] 1. Sludge conditioner

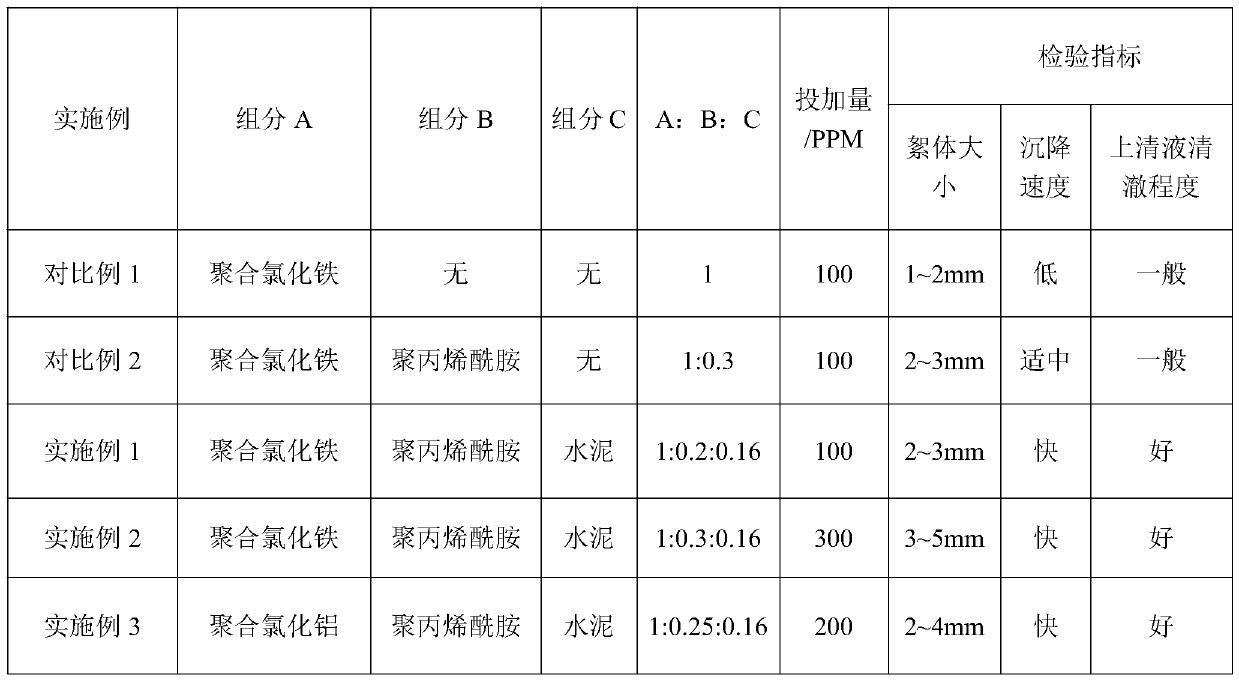

[0036] A sludge conditioner, comprising component A, component B and component C; the mass ratio of the component A, component B and component C is 1:0.2~0.5:0.15~0.2; wherein, the The component A is polyferric chloride or polyaluminum chloride, the component B is polyacrylamide, and the component C is cement. The specific ingredients and proportioning are shown in Table 1.

[0037] Table 1 The specific components and proportions of component A, component B and component C

[0038]

[0039] It can be seen from the above table that compared with the sludge flocs formed in Comparative Examples 1 and 2, the sludge flocs formed in Comparative Examples 1 and 2 were small, the sedimentation velocity was low, and the clarity of the supernatant was average. The sludge flocs formed in Examples 1-4 were large, the sedimentation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com