In-plane biaxial piezoresistive acceleration sensor chip and preparation method thereof

An acceleration sensor and chip technology, applied in the direction of acceleration measurement using inertial force, piezoelectric/electrostrictive/magnetostrictive devices, impedance networks, etc., can solve problems such as low sensitivity, low natural frequency, and large input impedance. Achieve the effects of alleviating the direct contradiction relationship, increasing the stress, and accurate thickness and dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

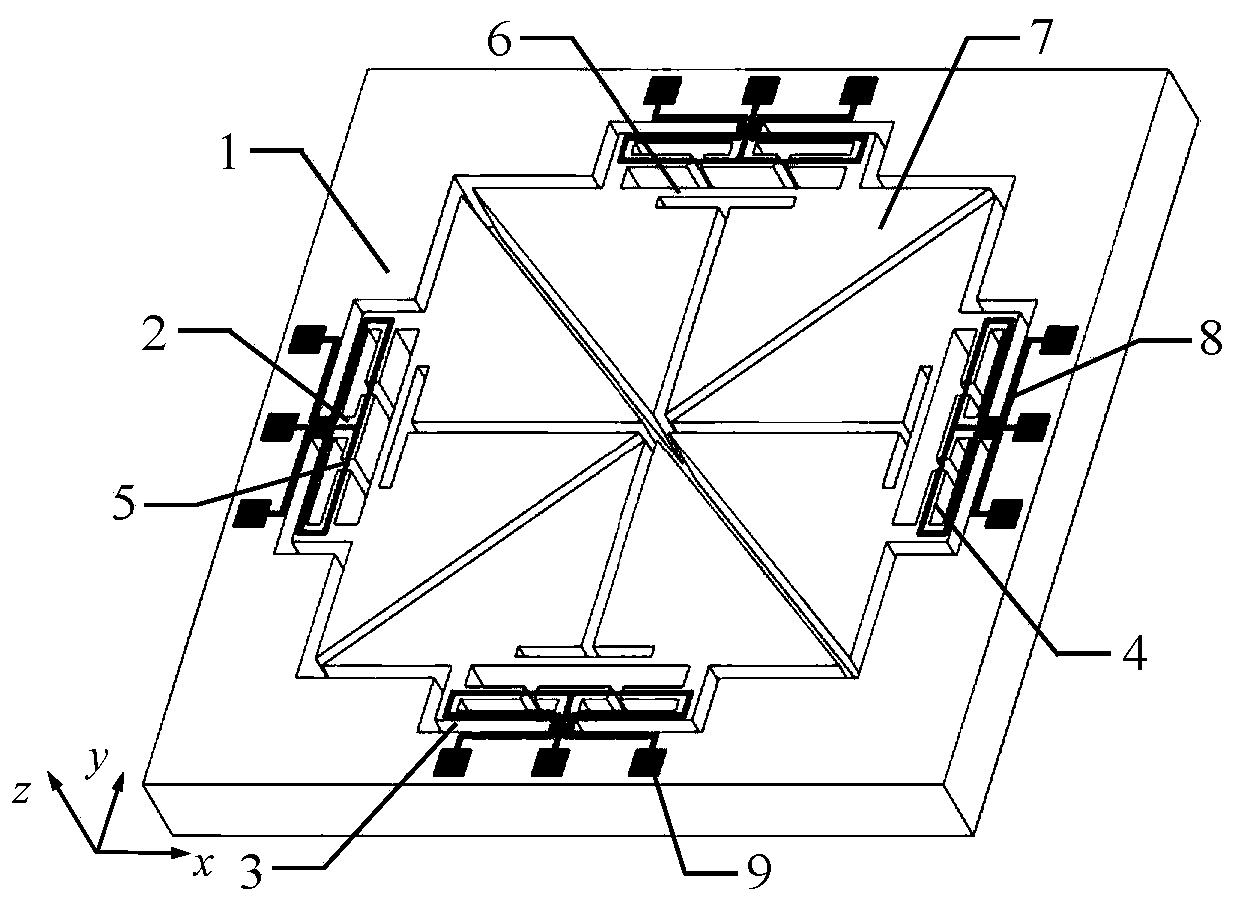

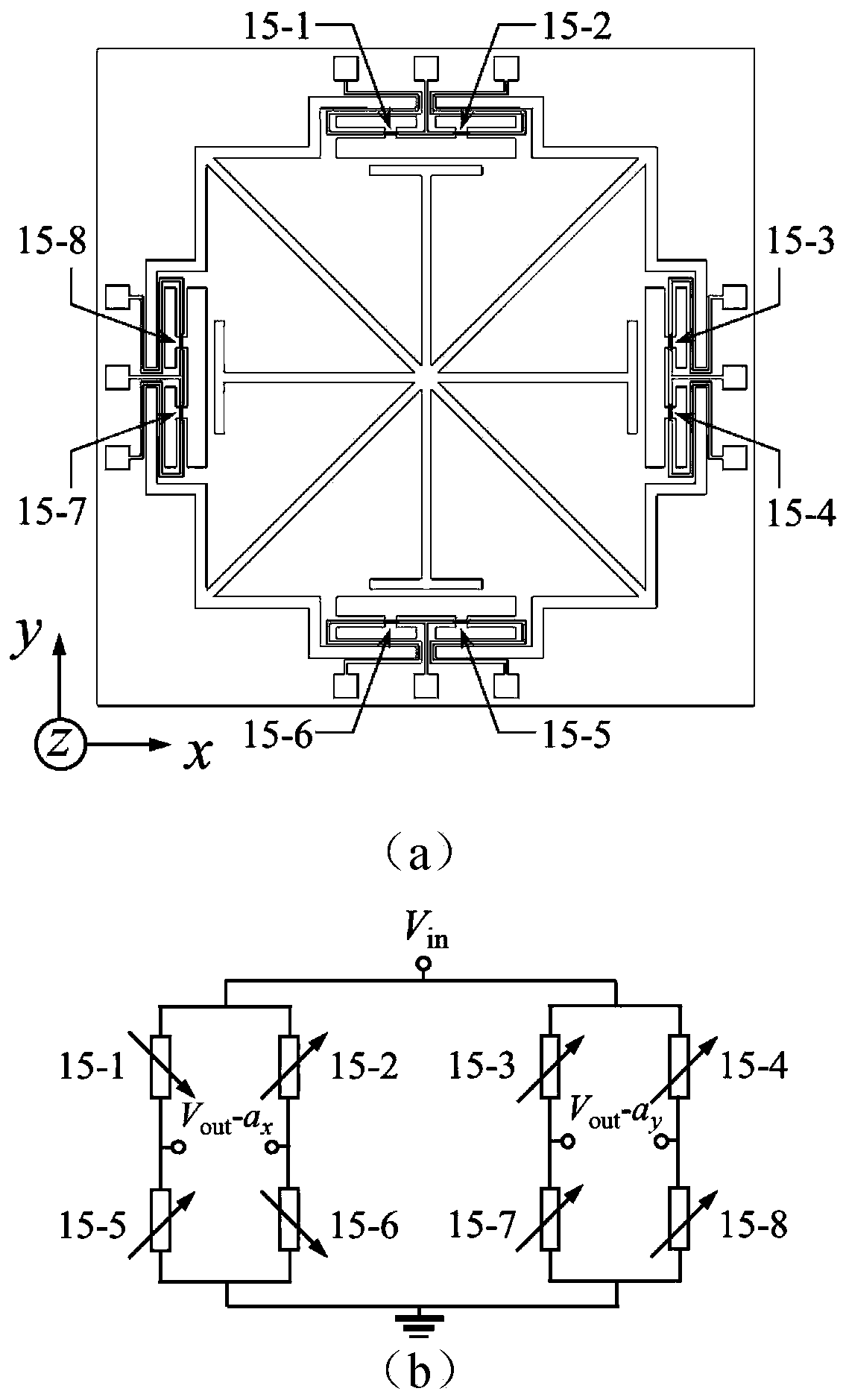

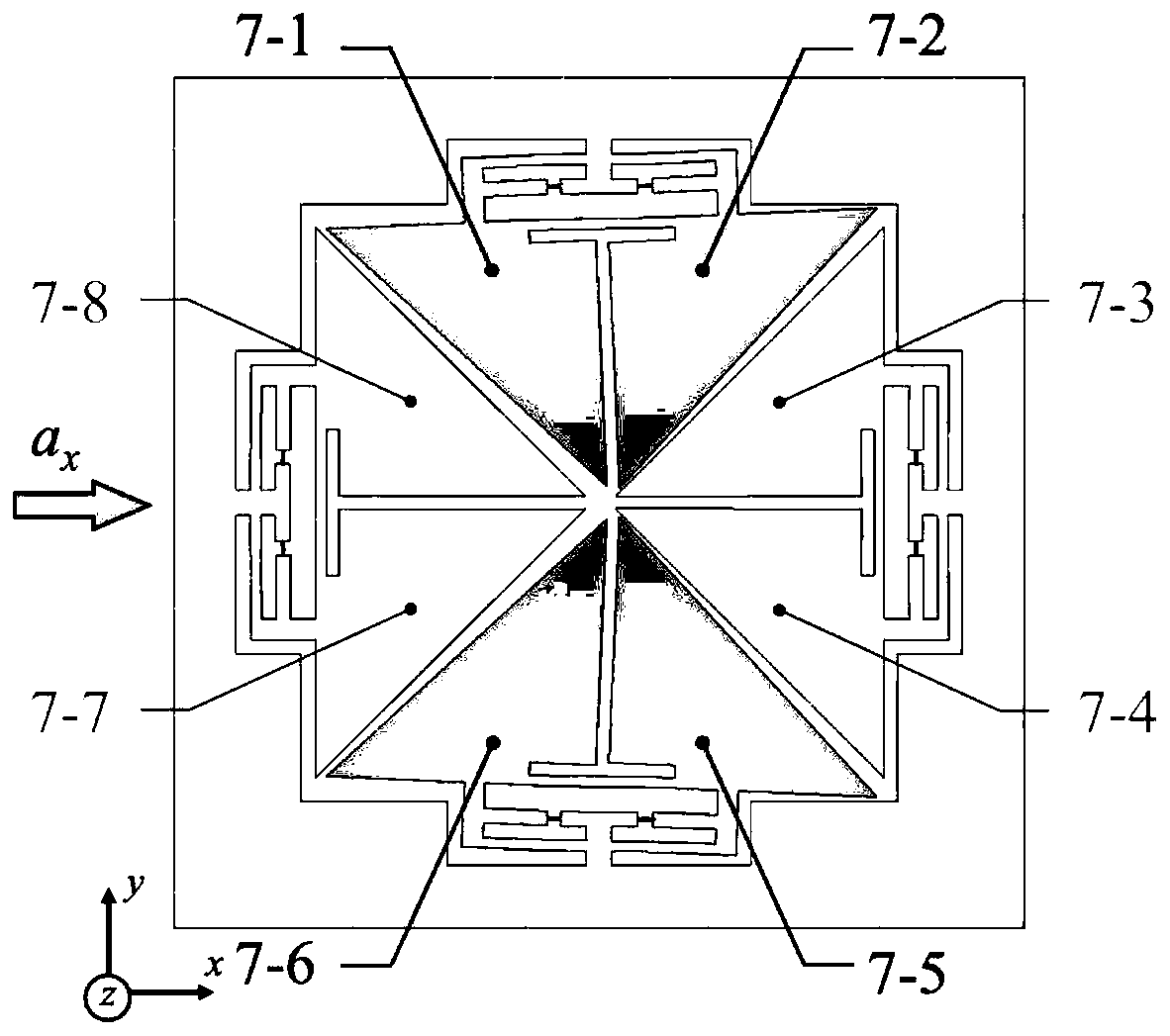

[0039] refer to figure 1 , an in-plane biaxial piezoresistive acceleration sensor chip, made of SOI silicon wafers, including a chip outer frame 1, the size of the chip outer frame 1 along the acceleration working direction is larger than the corresponding size of the mass block 7 on the side adjacent to it, the chip The middle part of each side of the outer frame 1 is provided with a fixed island 2, and the support beam 3 is an "L"-shaped structure. One end of the longer section is fixed to the outer frame 1 of the chip through the fixed island 2, and the shorter section is sequentially connected with the extension beam 4 and the The mass blocks 7 are connected, and the sensitive piezoresistive microbeams 5 are arranged in the gap between the end of the extension beam 4 and the fixed island 2, and are symmetrically distributed on both sides of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com