Method for enriching polyunsaturated fatty acid in grease

A technology of unsaturated fatty acids and oils, which is applied in the field of enrichment of polyunsaturated fatty acids, can solve the problems of complex steps and high cost of enzyme preparations, and achieve the effect of mild conditions and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

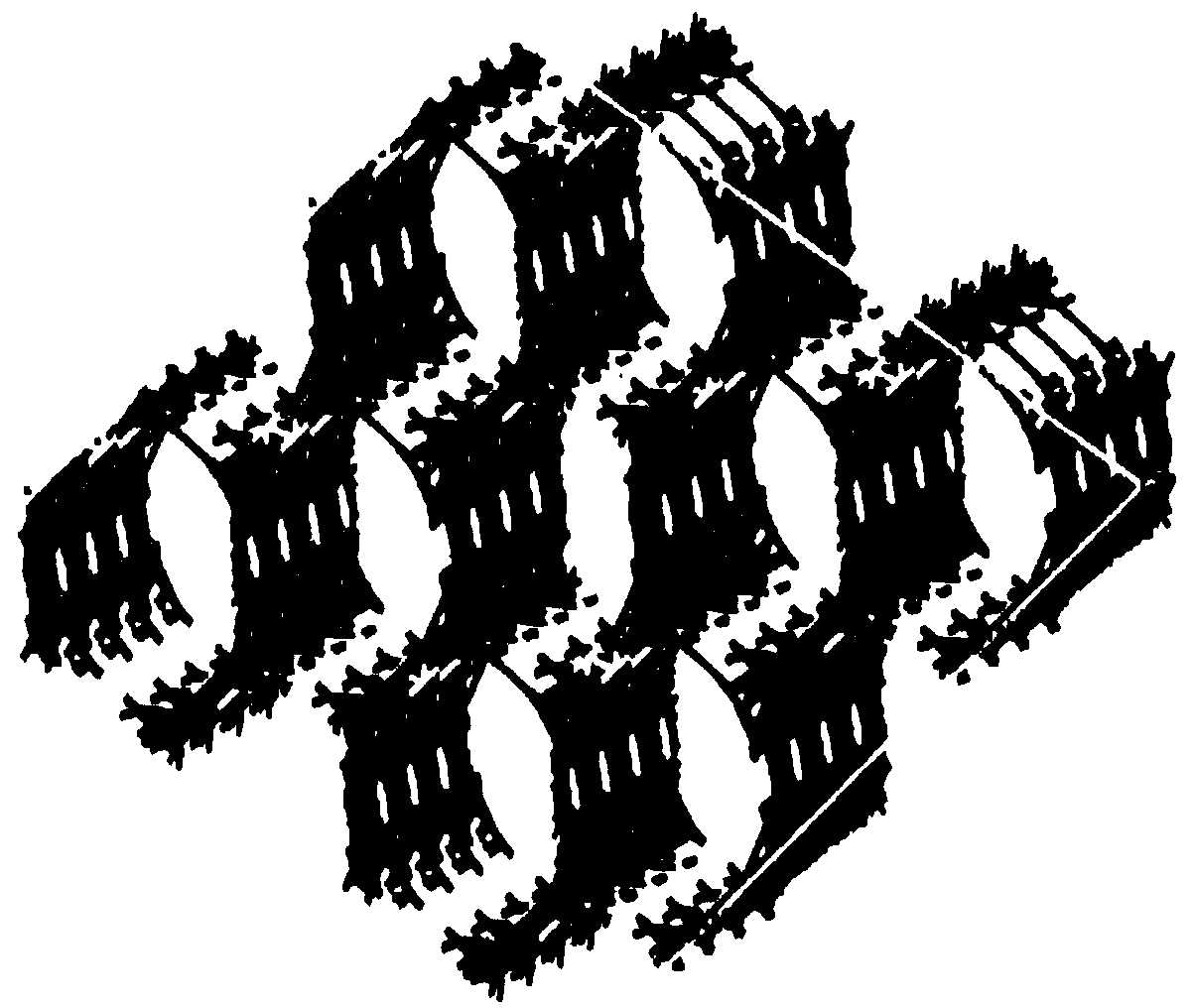

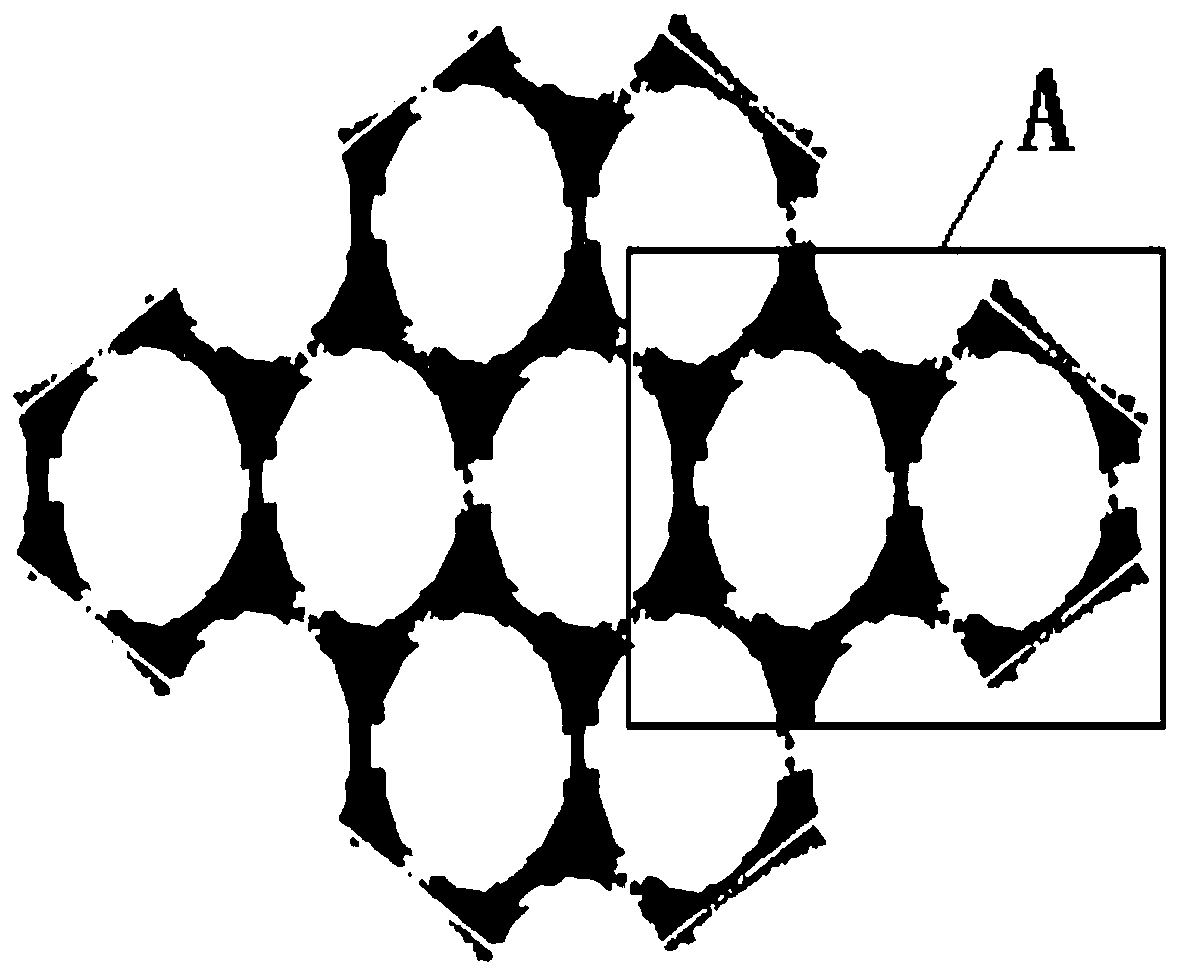

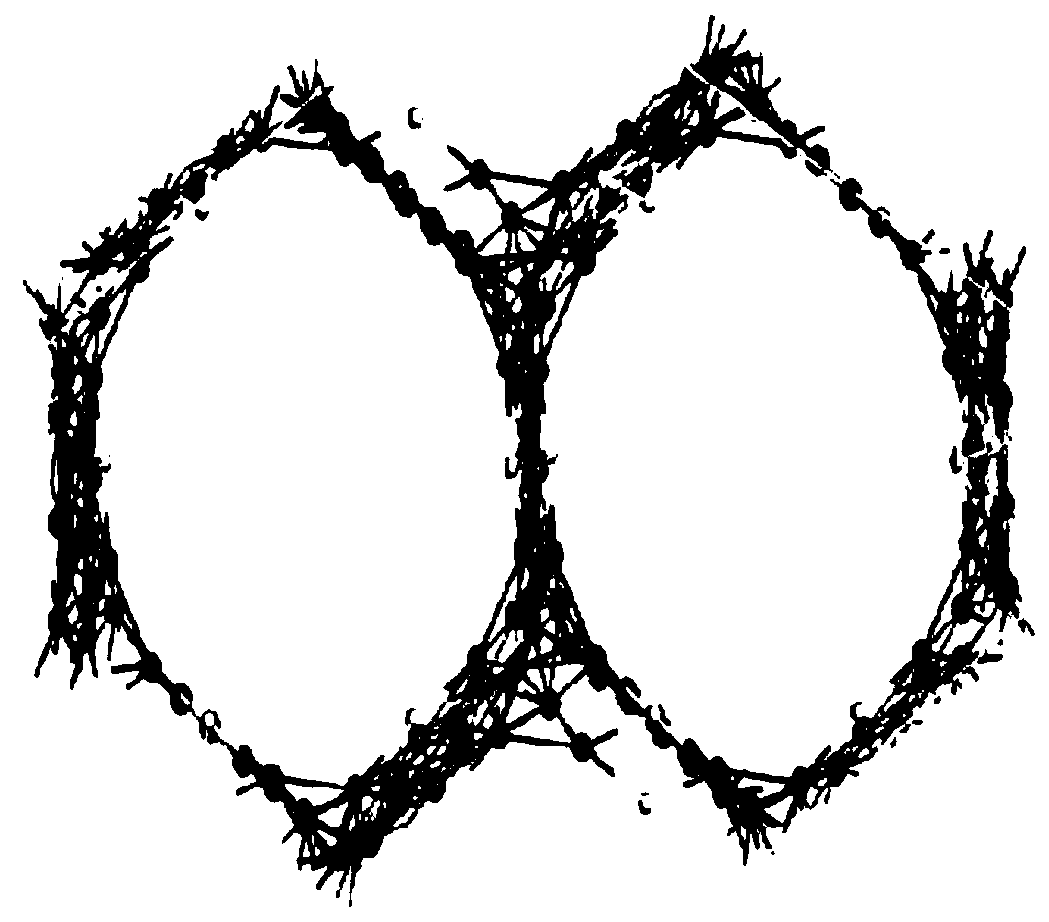

[0042] Embodiment 1: Preparation of Fe-MOF74 particles

[0043] (1) 288 grams of Fe(NO 3 ) 2 .6H 2O and 553 grams of 2,5-dimethylolterephthalic acid were dissolved in 5 L of solvent prepared from ethanol, water and N,N dimethylformamide (DMF) in a volume ratio of 1:2:2 It is formed, bubbled with argon for 15 minutes to remove the air in the solution, then sealed the solution and heated at 100°C for 24 hours, cooled to room temperature, filtered, and the solid powder product was repeatedly soaked and extracted with methanol 4 times, each time using 5L Soak in methanol for 12 hours, then dry the solid powder product at 150°C for 6 hours, and finally obtain 602.5 grams of the product, and use a pulverizer to crush it to 50 meshes to obtain an iron-terephthalic acid organometallic framework compound (Fe-MOF74). The pore size is about 1.46nm, and the specific surface area is 1020m 2 / g.

[0044] (2) Take 500 grams of Fe-MOF74 powder and add it to the swing granulator. After op...

Embodiment 2

[0048] Embodiment 2: Preparation of Zn-MOF74 particles

[0049] (1) 299 grams of Zn(NO 3 ) 2 .6H 2 O and 594 grams of 2,5-dihydroxybutyl terephthalic acid were dissolved in 6 L of solvent prepared from ethanol, water and N,N dimethylformamide (DMF) in a volume ratio of 1:1:1 It is formed, bubbled with argon for 15 minutes to remove the air in the solution, then sealed and placed at 120 ° C for 12 hours, cooled to room temperature, filtered, and the solid powder product was repeatedly soaked and extracted with methanol twice, each soaked in 8L of methanol 8h, then dry the solid powder product at 120°C for 12h, and finally obtain 704.6 grams of the product, use a pulverizer to crush it to 100 mesh, and obtain the zinc-terephthalic acid organometallic framework compound (Zn-MOF74), the pore size The size is about 1.42nm, and the specific surface area is 1130m 2 / g.

[0050] (2) Take 500 grams of Zn-MOF74 powder, add it to the swing granulator, and slowly spray 150 mL of sodi...

Embodiment 3

[0053] Example 3 Enrichment of DHA in Schizochytrium algae oil

[0054] Get 500 grams of Fe-MOF74 particles prepared in Example 1 and fill them into a glass tube for column chromatography with a diameter of 60 mm, then slowly add 250 mL of Schizochytrium algae oil (containing DHA 40%) from the mouth of the tube, fill the glass tube and After immersing the Fe-MOF74 particles, let it stand for 2 hours, then release the adsorbed oil, collect the Fe-MOF74 adsorption material, put the adsorption material in a high-speed centrifuge for centrifugation at a speed of 8000r / min, and centrifuge for 10 minutes to collect and enrich DHA The Schizochytrium algae oil was 200mL with a DHA content of 50%. The DHA content in the oil was tested according to the national standard GB5009.168; the enrichment operation was repeated three times to obtain 85mL of the Schizochytrium algae oil rich in DHA with a DHA content of 75%.

[0055] After centrifugation, the Fe-MOF74 adsorption material can be r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com