Composite zinc cathode with inorganic functional modification layer in water system battery and preparation method thereof, and application of composite zinc cathode with inorganic functional modification layer in water system battery

A modified layer and zinc negative electrode technology, applied to composite zinc negative electrode and its preparation method and application field, can solve the problems of affecting battery safety performance and cycle stability, reducing cycle efficiency, battery short circuit, etc., achieving easy to enlarge application, specific surface area Great, improve the effect of battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A 0.05 mg / μl polyvinylidene fluoride (PVDF) binder was prepared. Adding polyvinylidene fluoride (PVDF) into a methylpyrrolidone (NMP) solution for magnetic stirring for 10 hours to obtain a uniformly dispersed binder solution;

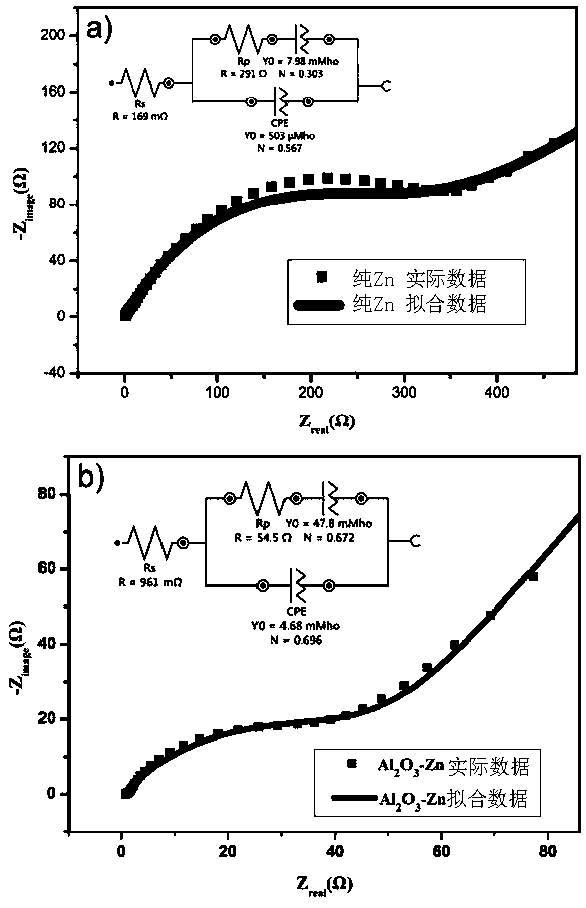

[0042] Weigh the alumina powder, acetylene black and polyvinylidene fluoride (PVDF) binder solution according to the mass percentage of 90:5:5, put it in a beaker, add a stirring magnet, place it on a magnetic stirrer and stir for 5 hours . The pretreatment of degreasing, decontaminating and deoxidizing the zinc foil is carried out, the zinc sheet is polished with sandpaper, then ultrasonicated, rinsed with deionized water and dried. Coat the uniformly mixed alumina slurry on the zinc foil with a thickness of 200 μm by doctor blade film-forming method, and dry it in an oven at 70°C to obtain a composite zinc negative electrode;

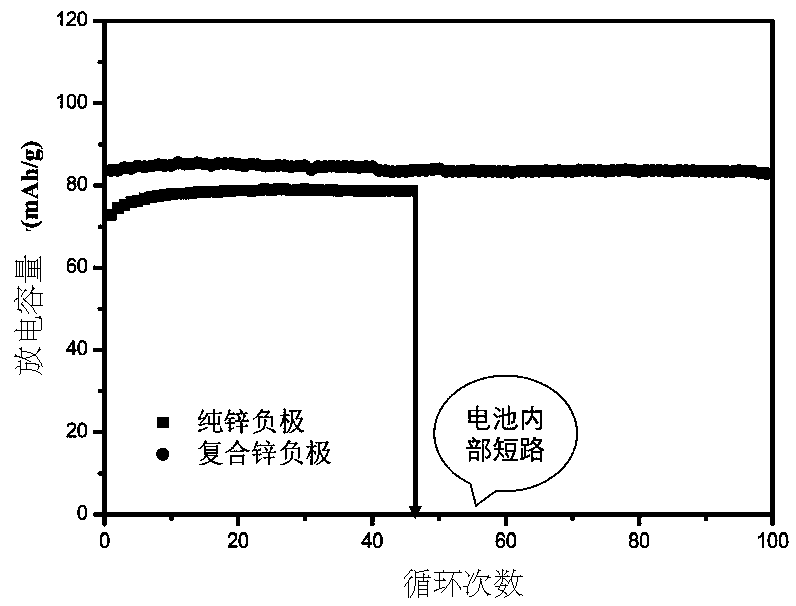

[0043] The full battery is assembled with lithium manganate as the positive electrode, polyethylene non-woven fabri...

Embodiment 2

[0047] A 0.05 mg / μl polyvinyl butyral (PVB) binder was prepared. Add polyvinyl butyral (PVB) into the alcohol solution for magnetic stirring, and the stirring time is 10 hours to obtain a uniformly dispersed binder solution;

[0048] Weigh the alumina powder, acetylene black and polyvinylidene fluoride (PVDF) binder solution according to the mass percentage ratio of 80:10:10, put it in a beaker, add a stirring magnet, place it on a magnetic stirrer and stir for 5 hours . The pretreatment of degreasing, decontaminating and deoxidizing the zinc foil is carried out, the zinc sheet is polished with sandpaper, then ultrasonicated, rinsed with deionized water and dried. Coat the uniformly mixed alumina slurry on zinc foil with a film-forming method of a doctor blade, with a thickness of 200 μm, and dry it in an oven at 70°C to obtain a composite negative electrode;

[0049] The full battery is assembled with lithium manganate as the positive electrode, polyethylene non-woven fabri...

Embodiment 3

[0053] A 0.02 mg / μl styrene-butadiene rubber (SBR) binder was prepared. Add styrene-butadiene rubber (SBR) into the toluene solution for magnetic stirring for 10 hours to obtain a uniformly dispersed binder solution;

[0054] The silica powder, graphite and styrene-butadiene rubber (SBR) binder solution were weighed according to the mass percentage ratio of 75:15:10 and placed in a beaker. After adding a stirring magnet, placed on a magnetic stirrer and stirred for 5 hours. The pretreatment of degreasing, decontaminating and deoxidizing the zinc foil is carried out, the zinc sheet is polished with sandpaper, then ultrasonicated, rinsed with deionized water and dried. Coat the uniformly mixed silicon oxide slurry on the zinc foil with a thickness of 200 μm by casting method, and put it into a 70°C oven to dry to obtain a composite negative electrode;

[0055] Figure 5 It is the constant current charge and discharge cycle life diagram of the manganese-based full battery assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com