Neodymium iron boron permanent magnet material preparation method

A permanent magnet material, NdFeB technology, used in magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of high cost, low reserves of heavy rare earth elements, reduction of magnet remanence and maximum magnetic energy product, etc. , to achieve the effect of good consistency, deep diffusion of heavy rare earths, and improved diffusion speed and depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The present invention provides a kind of preparation method of NdFeB permanent magnet material, comprises the following steps:

[0016] Step 1: Carry out orientation molding and isostatic pressing treatment of NdFeB magnetic powder to make NdFeB magnet green body;

[0017] Step 2: Deposit aluminum hydride on the surface of the manufactured NdFeB magnet green body, with a deposition thickness of 11-12 μm;

[0018] Step 3: mixing dysprosium-iron alloy powder with ethanol in a weight ratio of 1:2-3 to prepare a diffusion liquid;

[0019] Step 4: Fully contact the NdFeB magnet green body with aluminum hydride deposited on the surface with the diffusion liquid for 1-3 hours, and the weight ratio of the NdFeB magnet green body with aluminum hydride deposited on the surface to the diffusion liquid is 100: 1-3;

[0020] Step 5: The NdFeB magnet green body after the contact reaction in Step 4 is subjected to secondary heating treatment. The temperature condition of the first s...

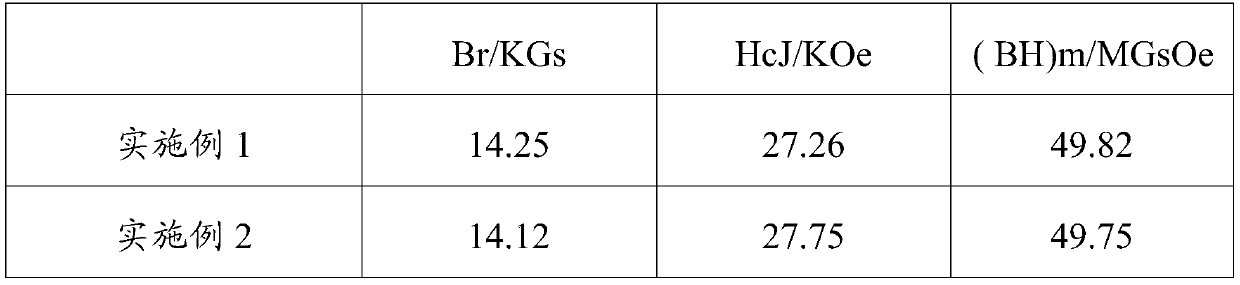

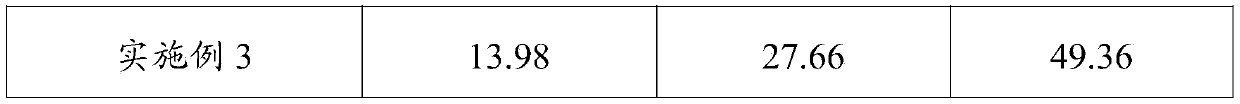

Embodiment 1

[0031] A preparation method of NdFeB permanent magnet material, comprising the following steps:

[0032] Step 1: Carry out orientation forming and isostatic pressing treatment of NdFeB magnetic powder to make NdFeB magnet green body, the orientation field size of the orientation forming is 1.5T, and the particle size of the NdFeB magnetic powder is less than 3 μm;

[0033] Step 2: Deposit aluminum hydride on the surface of the manufactured NdFeB magnet green body, with a deposition thickness of 11 μm;

[0034] Step 3: mixing dysprosium-iron alloy powder with ethanol at a weight ratio of 1:2 to prepare a diffusion liquid;

[0035] Step 4: Fully contact the NdFeB magnet green body with aluminum hydride deposited on the surface with the diffusion liquid for 1 h, and the weight ratio of the NdFeB magnet green body with aluminum hydride deposited on the surface to the diffusion liquid is 100: 1;

[0036] Step 5: The NdFeB magnet green body after the contact reaction in step 4 is ...

Embodiment 2

[0039] A preparation method of NdFeB permanent magnet material, comprising the following steps:

[0040] Step 1: Carry out orientation molding and isostatic pressing treatment on the NdFeB magnetic powder to make an NdFeB magnet green body, the orientation field of the orientation molding is 1.7T, and the particle size of the NdFeB magnetic powder is less than 3 μm;

[0041] Step 2: Deposit aluminum hydride on the surface of the manufactured NdFeB magnet green body, with a deposition thickness of 11 μm;

[0042] Step 3: mixing dysprosium-iron alloy powder with ethanol at a weight ratio of 1:2 to prepare a diffusion liquid;

[0043] Step 4: Fully contact the NdFeB magnet green body with aluminum hydride deposited on the surface with the diffusion liquid for 2 hours, and the weight ratio of the NdFeB magnet green body with aluminum hydride deposited on the surface to the diffusion liquid is 50: 1;

[0044] Step 5: The NdFeB magnet green body after the contact reaction in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com