Hot air and vacuum pulsation combined drying method and equipment based on temperature and humidity control

A technology of temperature and humidity control and vacuum pulsation, which is applied in lighting and heating equipment, dryers for stationary materials, and drying of solid materials by heating, etc. It can solve unreasonable exhaust gas emissions, poor convective heat transfer effect of hot air, and affect drying efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

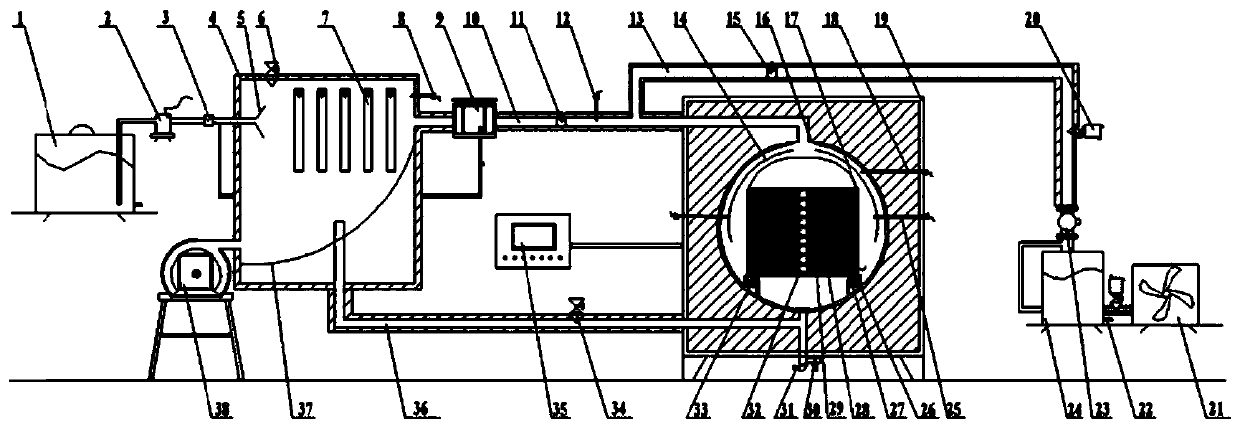

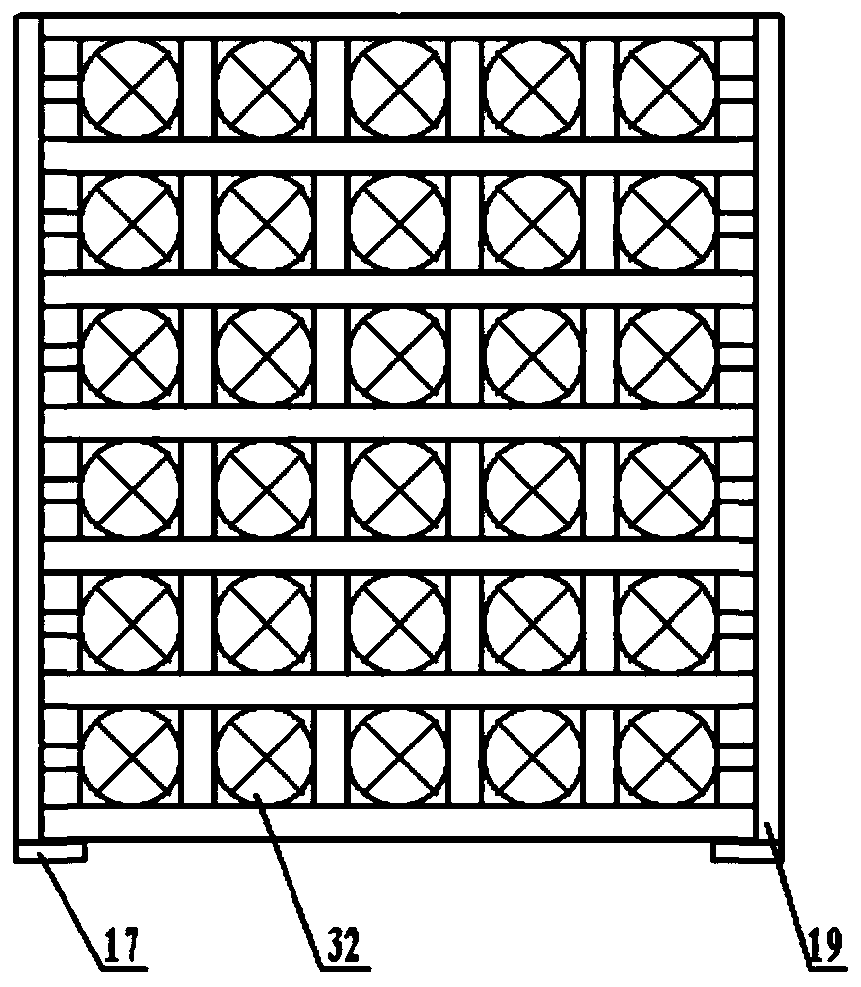

[0086] like figure 1 and figure 2 As shown, a temperature and humidity controlled hot air and vacuum pulsating combined drying equipment includes: a circulating hot air drying system, a combined drying body, a pulsating vacuum generating system, a vacuum heating system and an automatic control system.

[0087]The circulating hot air drying system includes a water tank 1, an atomizing pump 2, an air heating box 4, a nozzle 5, a heating pipe 7, an electric air heating device 9, a hot air inlet pipeline 10, a hot air return pipeline 36, a deflector 37, Centrifugal variable frequency fan 38 and axial flow fan 32; Wherein,

[0088] The water tank 1 and the first side of the air heating tank 4 are connected through a first pipeline, and an atomizing pump 2 is arranged on the first pipeline between the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com