High-anisotropy rare earth hard magnetic nano-particles and preparation method thereof

An anisotropic, nanoparticle technology, applied in the field of rare earth hard magnetic nanometers, can solve the problems of runaway, rapid growth, and uncontrollable size of alloy nanoparticles, and achieve ordered crystallization temperature reduction, controllable size, and composition. tuning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] One aspect of the embodiments of the present invention provides a method for preparing highly anisotropic rare earth hard magnetic nanoparticles, which includes:

[0029] Provide Sm(Co 1-x Ni x ) y Target and / or Sm(Co 1-x Cu x ) y Target material, wherein x is 0.2 to 0.8, and y is 2 to 10;

[0030] The Sm(Co 1-x Ni x ) y Target and / or Sm(Co 1-x Cu x ) y The target material is placed in a nano-cluster deposition system for nano-cluster deposition to obtain highly anisotropic rare earth hard magnetic nanoparticles.

[0031] As one of the preferred schemes, the conditions for the deposition of nanoclusters include: the pressure of the deposition chamber is below 1000 Pa, the flow rate of the working gas is below 1000 sccm, the flow rate of the transmission medium is below 1600 sccm, and the flight heating temperature is from room temperature to 1000 ° C. The distance between the cluster source and the substrate is less than 100cm, the power is less than 100W, a...

Embodiment 1

[0062] SmCo 5 , Sm(Co 0.7 Ni 0.3 ) 5 and Sm(Co 0.7 Cu 0.3 ) 5 Weigh high-purity Sm, high-purity Co, high-purity Ni and high-purity Cu corresponding to the mass, mix the corresponding proportion of elements, and then use the same method to prepare three kinds of targets respectively.

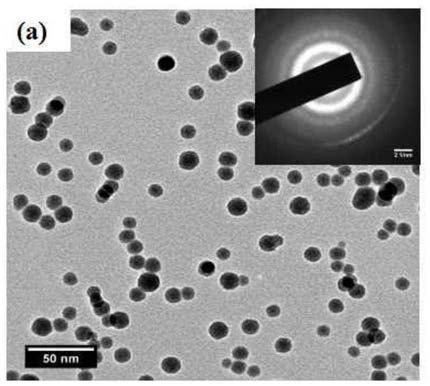

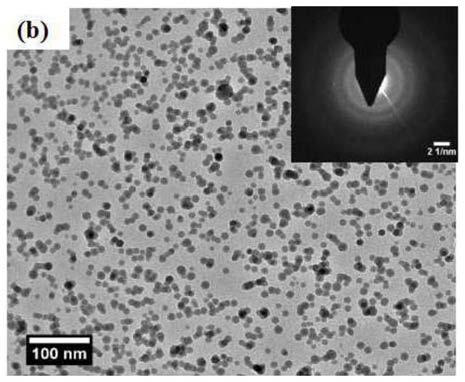

[0063] SmCo 5 , Sm(Co 0.7 Ni 0.3 ) 5 and Sm(Co 0.7 Cu 0.3 ) 5 Put the target material into the cluster source position of the equipment, put the substrate / micro-grid carbon film into the deposition chamber, and pump until the vacuum of the deposition chamber reaches 1.5*10 -8 Below mbar, turn on the circulating water, adjust the position of the cluster source to 100mm, set the flow rate of Ar gas and He gas to 98sccm and 30sccm respectively, and the pressure of the deposition chamber to 110Pa, use 0.2A, 0.3A and 0.2A sputtering respectively current and a sputtering voltage of 160V to deposit SmCo 5 , Sm(Co 0.7 Ni 0.3 ) 5 and Sm(Co 0.7 Cu 0.3 ) 5 Nanoparticles, and according to...

Embodiment 2

[0067] SmCo 5 , Sm(Co 0.7 Cu 0.3 ) 5 and Sm(Co 0.7 Ni 0.3 ) 5 Weigh high-purity Sm, high-purity Co, high-purity Ni and high-purity Cu corresponding to the mass, mix the corresponding proportion of elements, and then use the same method to prepare three kinds of targets respectively.

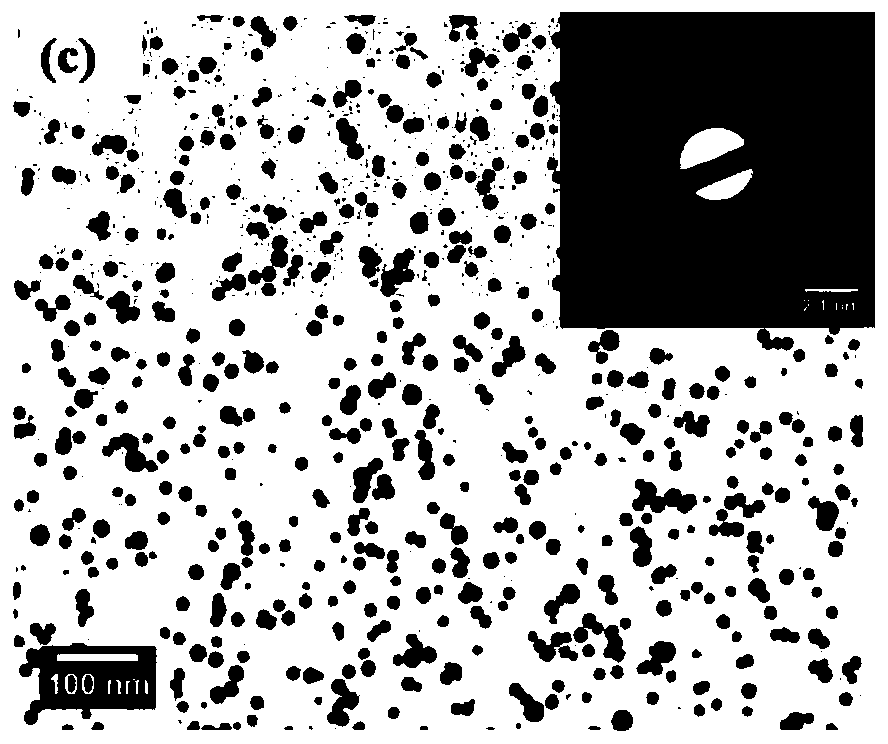

[0068] SmCo 5 , Sm(Co 0.7 Ni 0.3 ) 5 and Sm(Co 0.7 Cu 0.3 ) 5 Put the target material into the cluster source position of the equipment, put the substrate / micro-grid carbon film into the deposition chamber, and pump until the vacuum of the deposition chamber reaches 1.5*10 -8 Below mbar, turn on the circulating water, adjust the position of the cluster source to 100cm, set the flow rates of Ar gas and He gas to 98sccm and 30sccm respectively, set the pressure of the deposition chamber to 110Pa, set the flight heating temperature to 750-820°C, and use 0.2A, 0.3A and 0.2A sputtering current and 160V sputtering voltage deposit SmCo 5 , Sm(Co 0.7 Ni 0.3 ) 5 and Sm(Co 0.7 Cu 0.3 ) 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com