Weather-resistant calcium-zinc stabilizer for PVC and preparation method thereof

A calcium-zinc stabilizer and weather-resistant technology, which is applied in the field of weather-resistant calcium-zinc stabilizer for PVC and its preparation field, can solve the problems of reducing PVC rigid products, reducing the softening point of products, poor lubricity, etc., so as to improve weather resistance and improve Weather resistance and thermal stability, the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

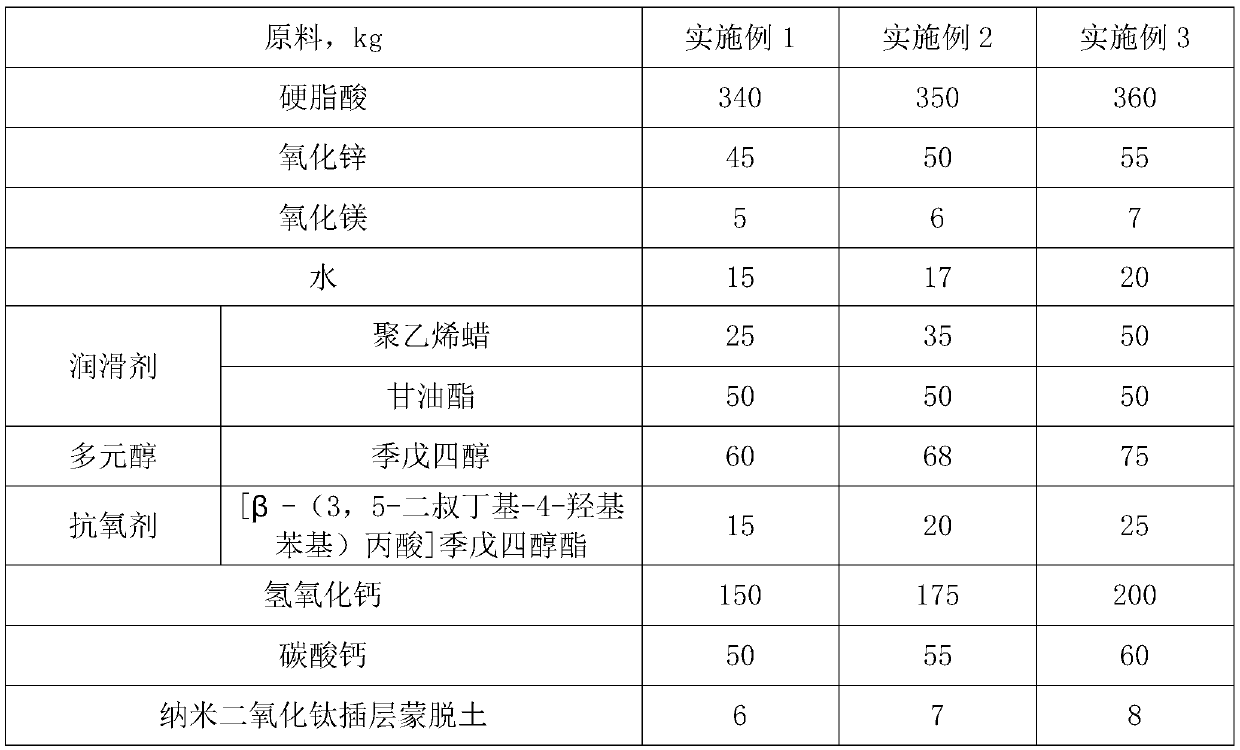

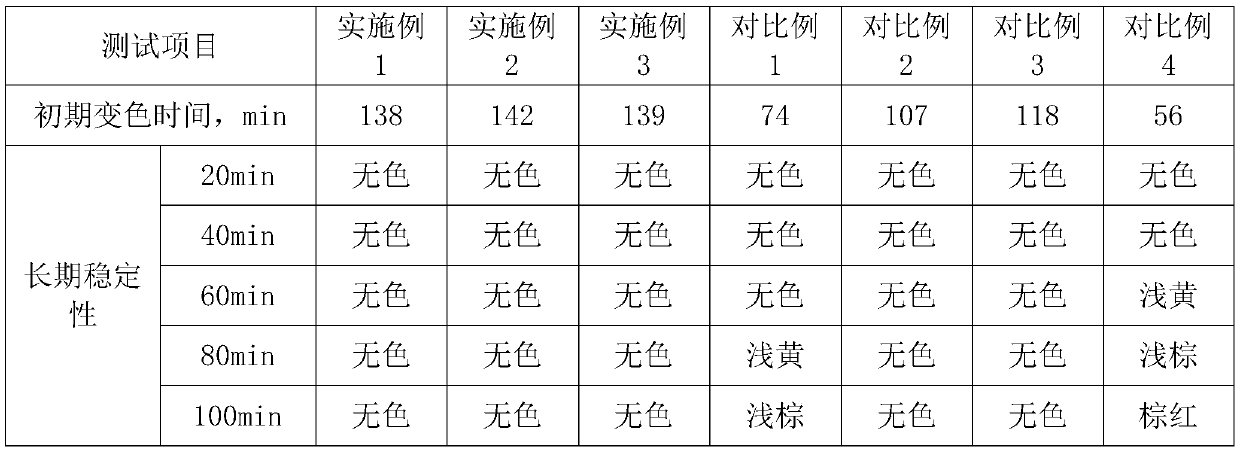

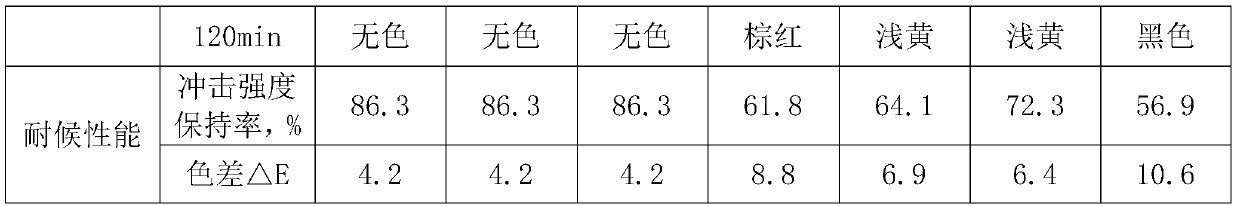

Examples

preparation example 1

[0034] Preparation Example 1: ① Mix tetraethoxytitanium with a molar ratio of 6:1 and hydrochloric acid and stir for 40 minutes to obtain a titanium dioxide sol;

[0035] ②Take 10kg montmorillonite, add 500kg, 2wt% sodium chloride solution, heat up to 60°C, stir for 30min; let it stand for 16h after natural cooling, and obtain a solidified product after filtering; wash and dry the solidified product, and then Place in 200kg of water and mix evenly to obtain sodium-based montmorillonite;

[0036] ③Take 10kg of titanium dioxide sol and the sodium-based montmorillonite solution in step ②, stir for 40min at a speed of 1000r / min at a temperature of 80°C; add 1kg of cetyltrimethylammonium bromide, and stir for 10min, The temperature was kept at 120° C. for 30 hours, and the mixture was obtained after filtration; after the mixture was washed and dried, it was placed at a temperature of 600° C. and burned for 2 hours to obtain nano-titanium dioxide intercalated montmorillonite.

preparation example 2

[0037] Preparation example 2: ①Mix tetraisopropoxytitanium and nitric acid with a molar ratio of 6:1 and mix and stir for 50 minutes to obtain titanium dioxide sol; ②Take 10kg montmorillonite, add 500kg, 2wt% sodium chloride solution, and heat up to 70°C , stirred for 45 minutes; left to stand for 18 hours after natural cooling, and filtered to obtain a solidified product; after the solidified product was washed and dried, it was placed in 200kg of water and mixed evenly to obtain sodium-based montmorillonite;

[0038] ③Take 12.5kg of titanium dioxide sol and the sodium-based montmorillonite solution in step ②, stir for 50min at a speed of 1250r / min at a temperature of 85°C; add 1.5kg of cetyltrimethylammonium bromide, and stir for 15min Finally, the mixture was kept at 125° C. for 35 hours, and filtered to obtain the mixture; after the mixture was washed and dried, it was placed at a temperature of 700° C. and burned for 2.5 hours to obtain nano-titanium dioxide intercalated m...

preparation example 3

[0039] Preparation example 3: ① Mix titanium tetrachloride and hydrochloric acid with a molar ratio of 6:1 and stir for 60 minutes to obtain a titanium dioxide sol;

[0040] ② Take 10kg montmorillonite, add 500kg, 2wt% sodium chloride solution, heat up to 80°C, stir for 60min; let it stand for 20h after natural cooling, and obtain a solidified product after filtering; wash and dry the solidified product, and then Place in 200kg of water and mix evenly to obtain sodium-based montmorillonite;

[0041]③Take 15kg of titanium dioxide sol and the sodium-based montmorillonite solution in step ②, and stir for 60min at a speed of 1500r / min at a temperature of 90°C; add 2kg of cetyltrimethylammonium bromide, and stir for 20min. The temperature was kept at 130° C. for 40 hours, and the mixture was obtained after filtration; after the mixture was washed and dried, it was placed at a temperature of 800° C. and burned for 3 hours to obtain nano-titanium dioxide intercalated montmorillonite....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com