A kind of preparation method of reinforced, flame-retardant carbonized rubber wood board

A technology of rubber wood and wood square, applied in the direction of wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of diversification of the color of carbonized wood at a single treatment temperature, unfavorable subsequent use of carbonized wood panels, and high processing temperature of carbonized wood panels. The effect of anti-corrosion treatment process, optimization of drying/carbonization process, and shortening of drying/carbonization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

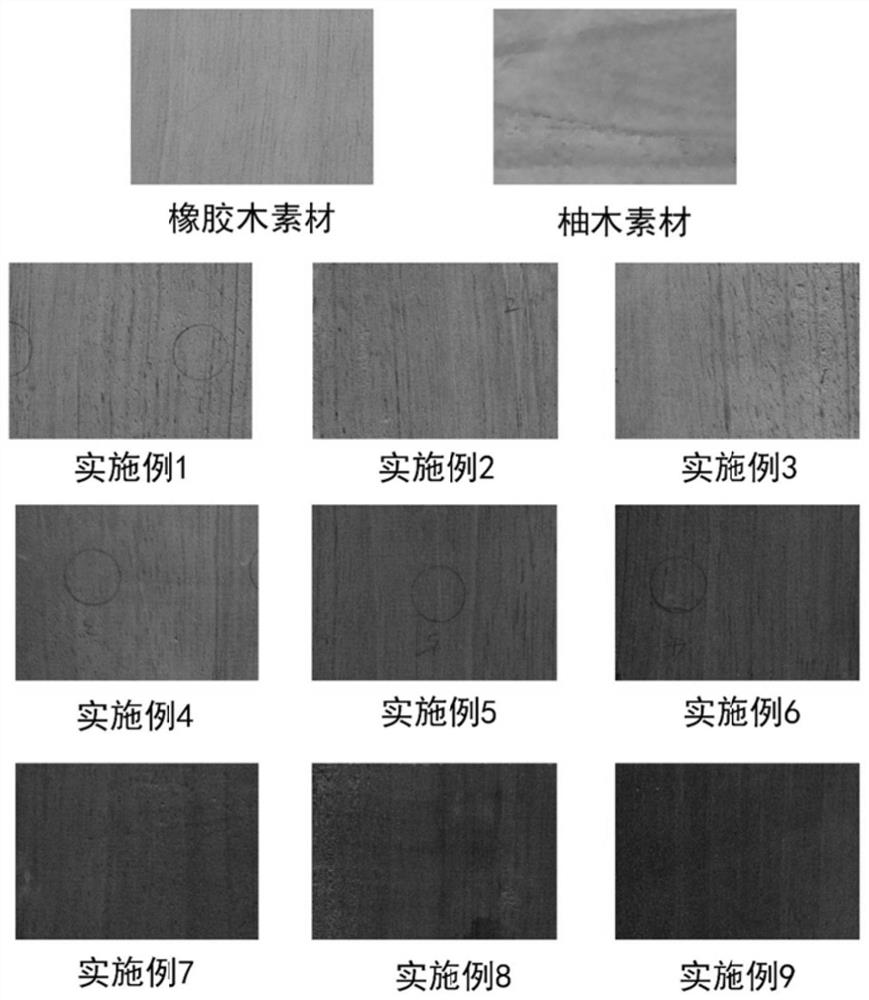

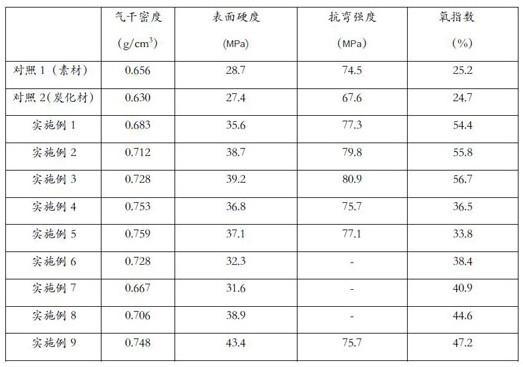

Examples

Embodiment 1

[0066] A kind of preparation method of reinforced, flame-retardant carbonized rubber wood board comprises the following steps:

[0067] (1) Saw rubber wood logs into wooden squares;

[0068] (2) Stack the rubber wood squares and place them in a high-temperature carbonization kiln or carbonization tank for preheating treatment; feed steam, and adjust the preheating temperature from 40°C to ensure that the dry and wet bulb temperatures rise synchronously. To 100°C, the treatment time is 24h;

[0069] (3) Stop feeding steam, continue heating and enter the low-temperature drying treatment stage, gradually increase the temperature from 100°C to 130°C, and the treatment time is 48h;

[0070] (4) In the stage of high-temperature carbonization treatment, continue to feed steam, adjust the carbonization temperature to 170°C, and process for 8 hours;

[0071] (5) In the cooling treatment stage, use atomized water to cool down to about 95°C, and the treatment time is 10 hours; adjust t...

Embodiment 2

[0079] The difference from Example 1 is that the water-soluble flame retardant and reinforcing liquid used in Example 2 are respectively: the water-soluble flame retardant is a mixture of 2 parts of boric acid, 8 parts of disodium tetraborate, and 100 parts of water.

[0080] The reinforcing fluid is water glass, which is made by mixing 30 parts of 40A water glass and 100 parts of water.

[0081] In addition, in Example 2, (2) Stack the rubber wood squares and place them in a high-temperature carbonization kiln or carbonization tank for preheating treatment; steam is introduced to ensure that the dry and wet bulb temperatures rise synchronously , adjust the preheating temperature from 40 to 100 ° C, and the treatment time is 48 hours; (7) Cut the impregnated wood into 2.0cm thick boards by multi-blade sawing.

Embodiment 3

[0083] The difference from Example 1 is that the water-soluble flame retardant and reinforcing liquid used in Example 5 are respectively: the water-soluble flame retardant is ammonium polyphosphate, diammonium hydrogen phosphate, boric acid, and its consumption is 4 parts of ammonium polyphosphate, Diammonium hydrogen phosphate 15 parts, boric acid 4 parts, water 100 parts.

[0084] The reinforcing fluid is water glass, and its dosage is 40 parts of 50A water glass and 100 parts of water.

[0085] In addition, in Example 3, (2) Stack the rubber wood squares and place them in a high-temperature carbonization kiln or carbonization tank for preheating; add steam to ensure that the dry and wet bulb temperatures rise synchronously Next, adjust the preheating treatment temperature from 40 to 100°C, and the treatment time is 36h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com