Novel steel-tube reinforced concrete-filled steel tubular member and processing method thereof

A new type of concrete filled steel tube technology, applied in the direction of manufacturing tools, ceramic molding machines, pillars, etc., to achieve the effect of weakening the lateral tension, increasing the bearing capacity, and effectively restraining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced. The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "side", etc., are for reference only The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

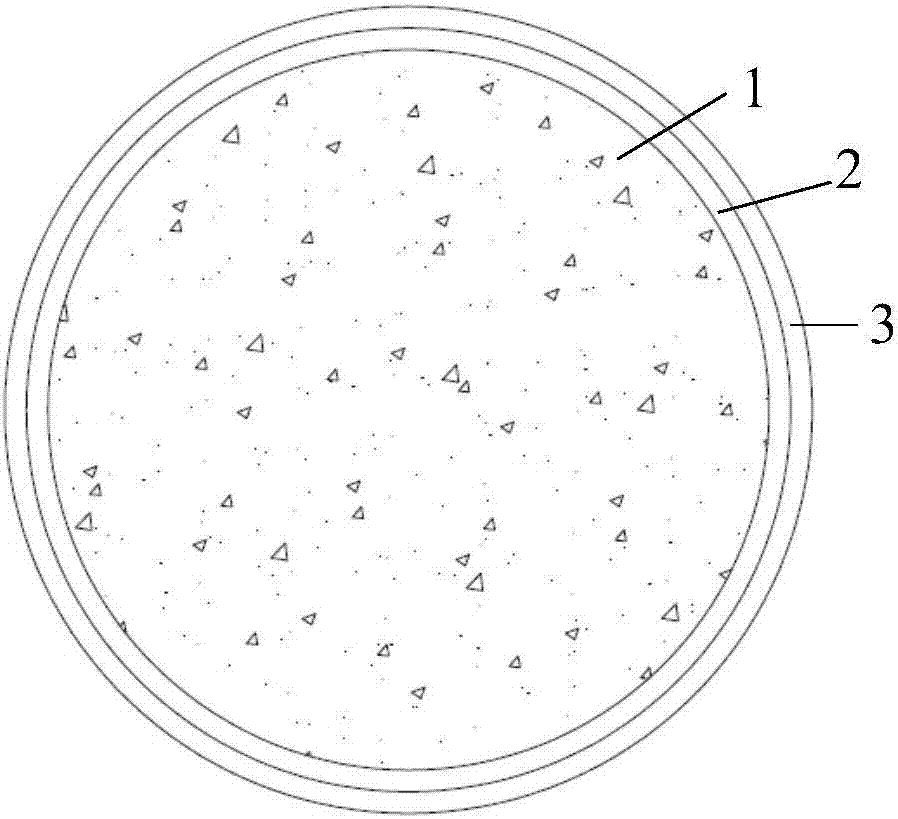

[0034] In this embodiment, both the core component and the outer layer component adopt a cylindrical structure, but the core component and the outer layer component of this solution can also be prepared with structures of other shapes.

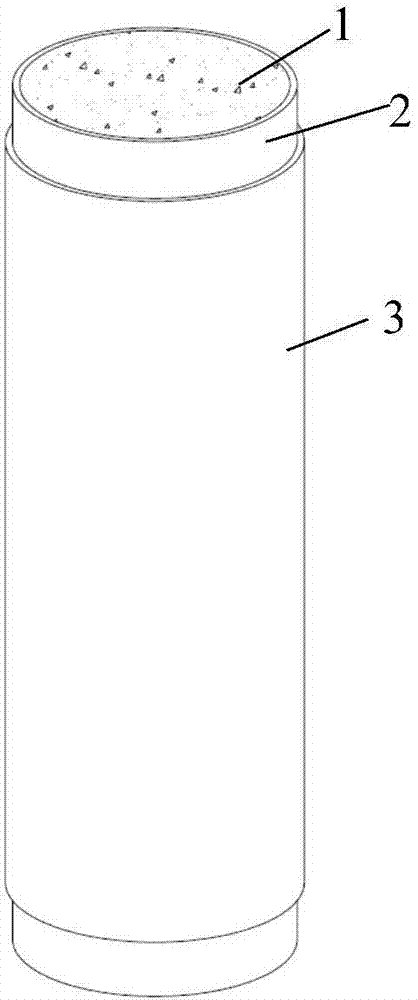

[0035] figure 1 It is a structural schematic diagram of a new steel-filled steel tube concrete member provided by an embodiment of the present invention. from figure 1It can be seen from the figure that the appearanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com