A high-efficiency prefabricated steam insulation pipe

A steam thermal insulation pipe and high-efficiency technology, applied in the directions of thermal insulation, pipeline protection through thermal insulation, pipeline protection, etc., can solve the problems of easy collapse of organic thermal insulation materials, decreased thermal insulation performance of thermal insulation pipes, and many joints in hard thermal insulation layers, etc. The effect of reducing the convective heat transfer efficiency, reducing the contact area and improving the heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

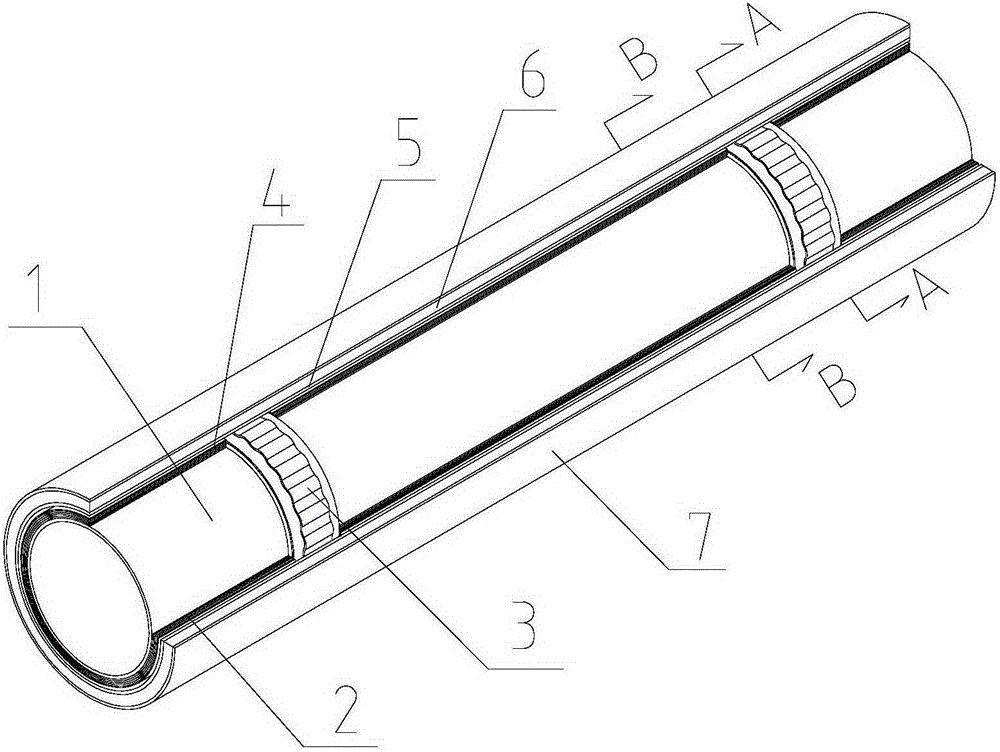

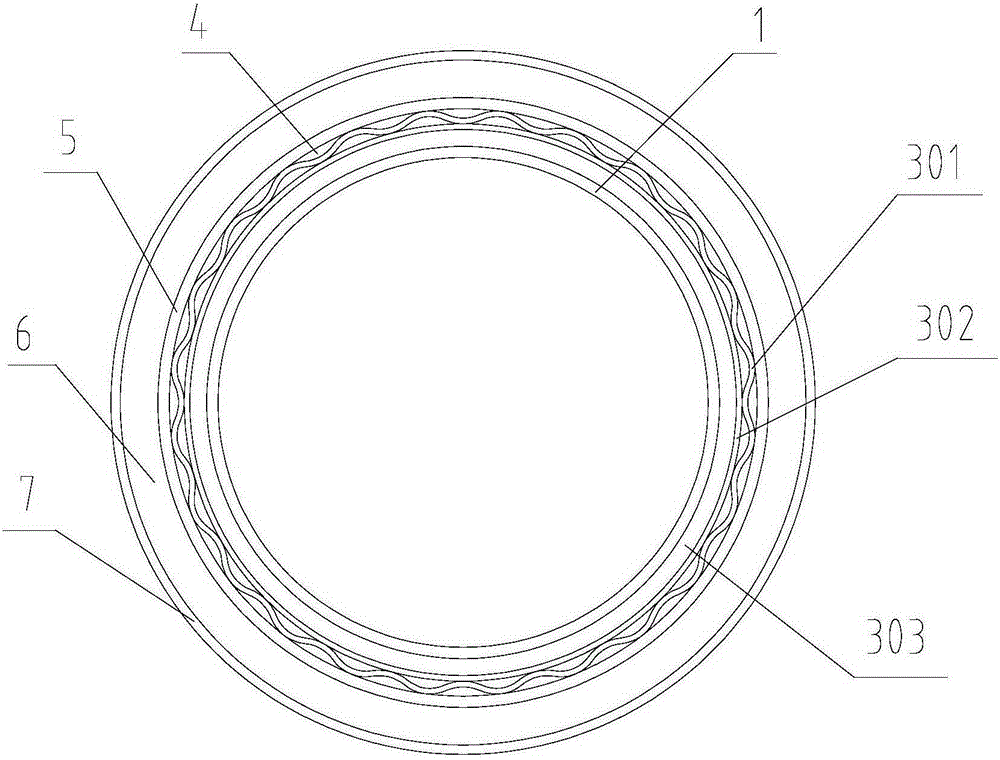

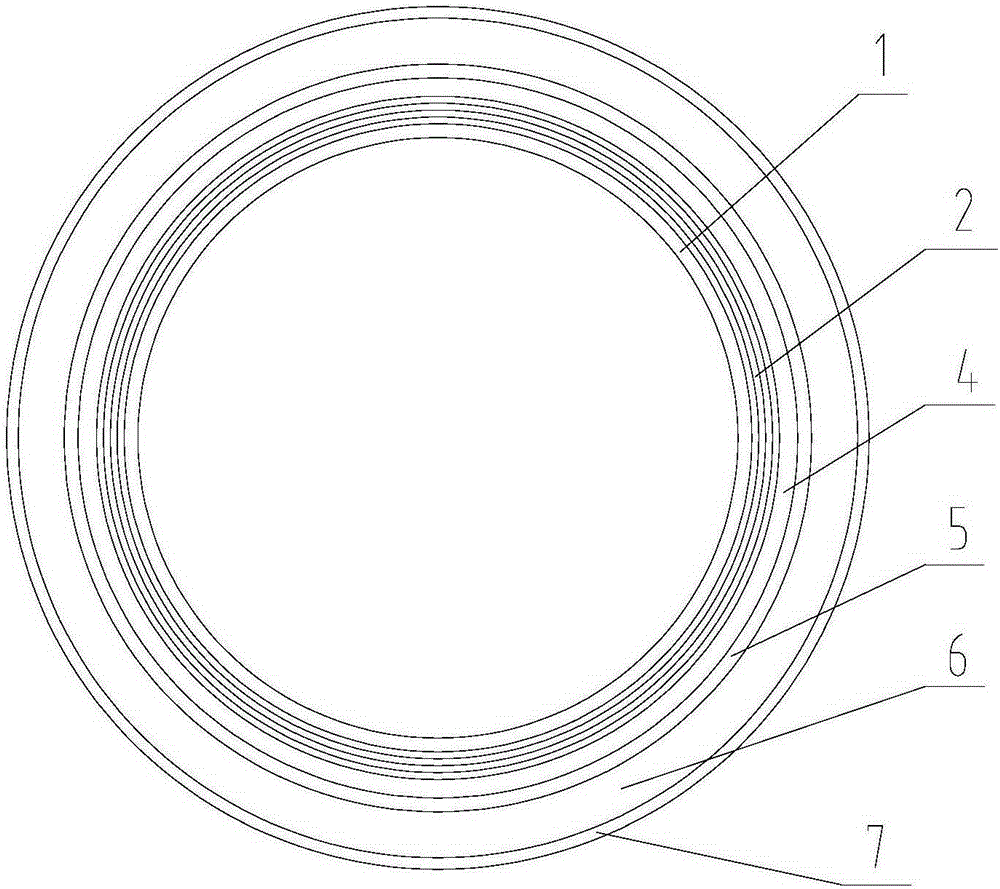

[0032] The high-efficiency prefabricated steam insulation pipe of this embodiment has a structure such as figure 1 , figure 2 , image 3 and Figure 7 As shown, it includes working steel pipe 1, first insulation layer 2, outer protection steel pipe 5, second insulation layer 6 and non-metallic outer protection pipe 7 from the inside to the outside, wherein the non-metallic outer protection pipe 7 adopts PE pipe, which can improve The anti-corrosion performance of the insulation pipe is used to fix the second insulation layer 6 and prevent the external environment from corroding the entire pipeline. The working steel pipe 1 is equipped with the first thermal insulation layer 2 and the sliding guide bracket 3 in sequence in the outer axial direction. 3 and the outer protective steel pipe 5 are provided with an air interlayer 4. In order to reduce the heat radiation in the high-temperature area, the first thermal insulation layer 2 is made of ultra-thin thermal insulation ma...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that the inner diameter of the bracket body 301 is slightly smaller than the outer diameter of the inner lining tube 302, so that the bracket body 301 and the inner lining tube 302 are in an interference fit, and the bracket body 301 is tightly hooped inside Liner 302. In addition, the ultra-thin heat insulation material is made of 20 layers of aluminum foil 202, and the thickness of a single layer of aluminum foil 202 is 0.01 mm.

Embodiment 3

[0039] The difference between this embodiment and Embodiment 1 is that the ultra-thin heat insulating material is made of 25 layers of aluminum foil 202, and the thickness of a single layer of aluminum foil 202 is 0.055mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com