Nano micropore thermal-insulation board and production method thereof

A technology of nano-micropores and heat insulation boards, which is applied to ceramic products, other household appliances, applications, etc., can solve the problems of increasing environmental pressure and waste water treatment costs, heat preservation performance is difficult to meet heat insulation needs, and energy consumption increases, etc., to achieve Improve the effect of heat insulation, good high temperature stability, and improve the effect of heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

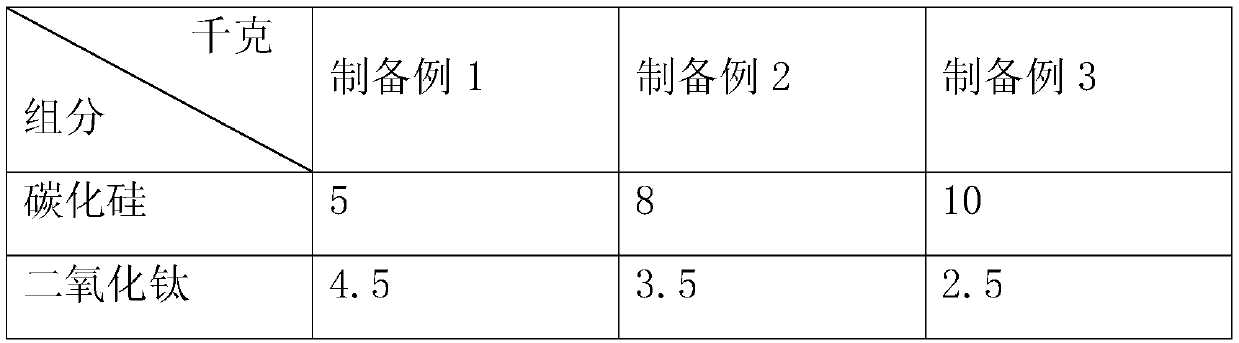

[0041] The raw material ratio of infrared radiation sunscreen agent in Table 1 preparation example 1-3

[0042]

preparation example 1

[0043] Preparation Example 1: According to the ratio in Table 1, first add 2.5kg of silicon carbide into the high-speed mixer, then feed 4.5kg of titanium dioxide powder into the upper layer of silicon carbide that has been added to the bottom of the high-speed mixer, and finally add the remaining 2.5kg Feed kg silicon carbide to the upper layer of titanium dioxide, turn on the high-speed mixer, adjust the speed to 100rpm, stir and mix for 5min, then adjust the speed to 800rpm, stir and mix for 10min.

preparation example 2

[0044] Preparation Example 2: According to the ratio in Table 1, first add 4kg of silicon carbide to the high-speed mixer, then feed 3.5kg of titanium dioxide powder into the upper layer of silicon carbide that has been added to the bottom of the high-speed mixer, and finally carbonize the remaining 4kg Feed silicon into the upper layer of titanium dioxide, turn on the high-speed mixer, adjust the rotation speed to 150 rpm, stir and mix for 8 minutes, then adjust the rotation speed to 900 rpm, and stir and mix for 13 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com